Battery cathode and preparation method thereof, lithium ion battery using the cathode

A lithium ion and negative electrode technology, which is applied to the battery negative electrode and the preparation method thereof and the battery field using the negative electrode, can solve the problems of poor safety performance and the like, and achieve the effect of high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

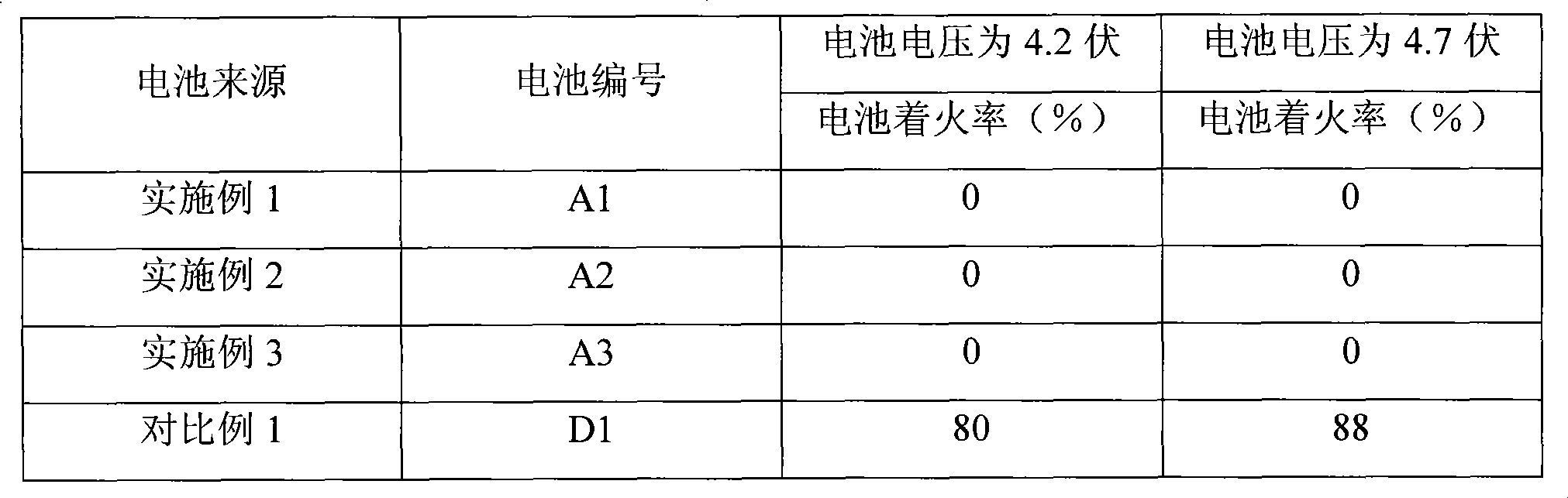

Examples

preparation example Construction

[0023] The preparation method of the negative electrode of the present invention comprises coating and / or filling the slurry A containing the negative electrode active material, the binder and the solvent on the current collector, drying, calendering or non-calendering, and forming a collector with the negative electrode material. The electric body, wherein, the method also includes coating the slurry B containing the negative electrode active material, the binder, the thermally conductive material and the solvent on the current collector with the negative electrode material, drying, calendering or non-calendering, and the negative electrode material A thermally conductive film layer is formed on it; the thermal conductivity of the thermally conductive material is above 50 W / (m·K), preferably 200-500 W / (m·K).

[0024] The thermally conductive material can be any material with a thermal conductivity of 50 W / (m·K) or more, for example, a metal material. Preferably, the thermally ...

Embodiment 1

[0042] This example illustrates the battery negative electrode of the present invention, the lithium ion battery using the negative electrode and their preparation methods.

[0043] (1) Preparation of negative electrode

[0044] Add 10 kg of negative electrode active material natural graphite (Showa, Japan, SLMG-AO) and 400 g of binder polytetrafluoroethylene into 4 kg of N-methylpyrrolidone, and then stir in a vacuum mixer to form a stable and uniform slurry a. The slurry A was evenly coated on a copper foil, dried at 120° C. for 0.5 hour, and then rolled to form a current collector with the negative electrode material.

[0045] 300 grams of negative electrode active material natural graphite (Showa Japan, SLMG-AO) and 6 grams of aluminum powder (thermal conductivity is 240 watts / (meter Kelvin), and the average particle diameter is 0.5 micron) are mixed uniformly to obtain a mixture, and the mixture Add 900 grams of N-methylpyrrolidone, then add 30 grams of polytetrafluoroe...

Embodiment 2

[0051] Prepare the battery according to the method of Example 1, the difference is that the negative electrode is prepared as follows:

[0052] Add 10 kg of negative electrode active material natural graphite (Showa, Japan, SLMG-AO) and 400 g of binder polytetrafluoroethylene into 4 kg of N-methylpyrrolidone, and then stir in a vacuum mixer to form a stable and uniform slurry a. The slurry A was evenly coated on a copper foil, dried at 120° C. for 0.5 hour, and then rolled to form a current collector with the negative electrode material.

[0053] 300 grams of negative electrode active material natural graphite (Showa Japan, SLMG-AO) and 9 grams of copper powder (thermal conductivity is 400 watts / (meter Kelvin), and the average particle diameter is 5 microns) are mixed uniformly to obtain a mixture, and the mixture Add 900 grams of N-methylpyrrolidone, then add 15 grams of polytetrafluoroethylene, mix uniformly to obtain slurry B, apply the slurry B to the current collector wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com