Denitrification processing method of coking wastewater and processing arrangement

A technology for coking wastewater and treatment method, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, and multi-stage water/sewage treatment, etc., can solve the problems of secondary pollution, high treatment cost, and difficulty in popularization and application, and saves power costs. , The effect of reducing ammonia nitrogen load and saving power cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

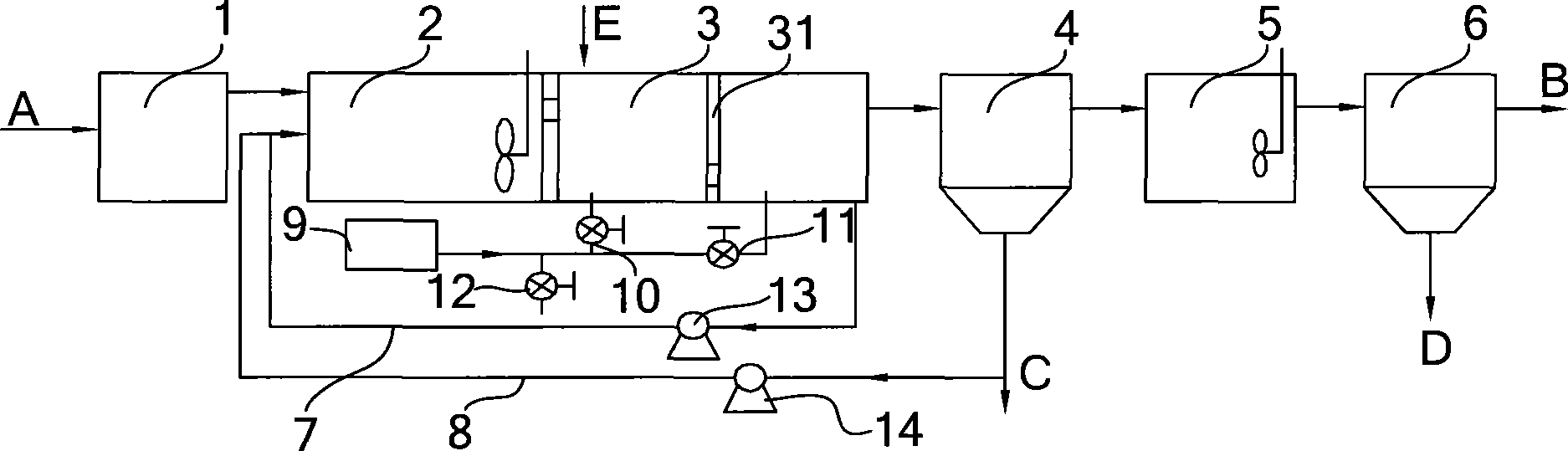

[0026] In this embodiment, the denitrification treatment method for coking wastewater includes the following steps: pretreatment, biochemical treatment aerobic reactor, biochemical treatment aerobic reactor, biochemical treatment secondary sedimentation tank, coagulation treatment (coagulation reaction tank, mixing Condensation and sedimentation tank), mainly to convert part of the ammonia nitrogen in the wastewater into nitrate and nitrite in the aerobic reactor, nitrate and part of the nitrite are denitrified and denitrified in the aerobic reactor, part of the nitrite Anaerobic ammonium oxidation denitrification is performed in a facultative reactor. This processing method uses the figure 1 The processing equipment shown specifically includes: air flotation tank unit 1, aerobic reactor 2, aerobic reactor 3, secondary sedimentation tank 4, coagulation reaction tank 5, coagulation sedimentation tank 6, mixed liquid return pipe 7. Sludge return pipe 8 and regulating valve (reg...

Embodiment 2

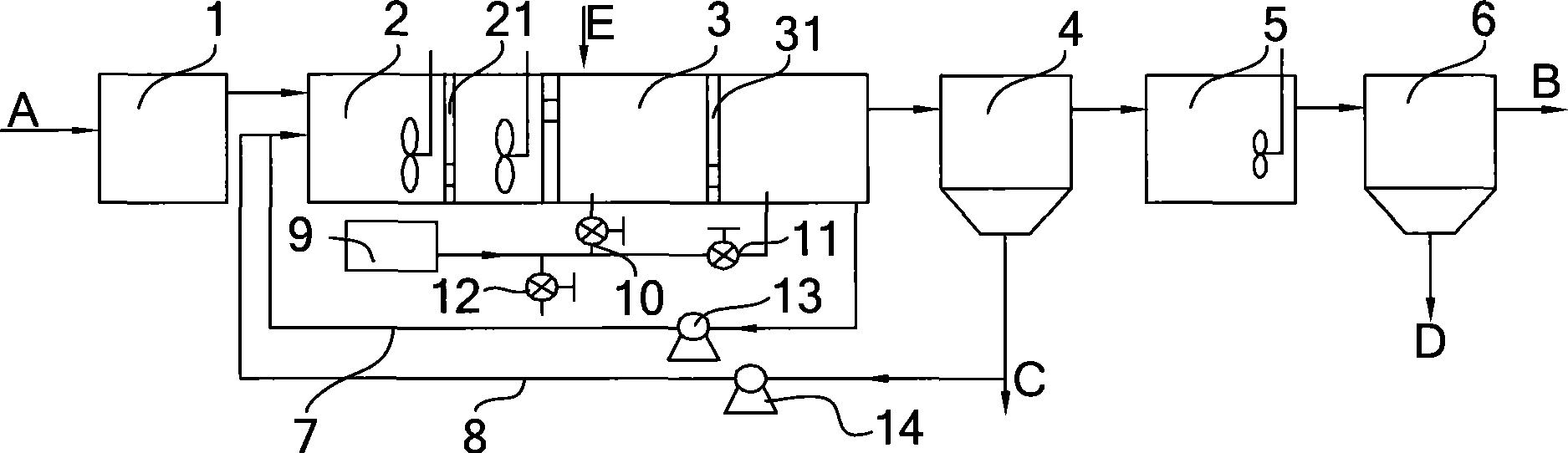

[0038] In this embodiment, the coking wastewater treatment denitrification treatment equipment such as figure 2 As shown, the anaerobic reactor of this equipment is divided into two parts by a partition wall, and a through hole is provided on the partition wall, and the two parts separated inside the anaerobic reactor are connected through the through hole. This structure is beneficial to the facultative and anaerobic The separation and enrichment of aerobic microorganisms increase the reaction rate of denitrification and anammox. The other structures of the equipment are the same as those in Embodiment 1. The treatment process of using this equipment to treat coking wastewater for denitrification is also the same as that of Example 1.

[0039] In summary, in the embodiment of the present invention, a biological denitrification process combining common nitrification / denitrification, short-cut nitrification, denitrification and anammox is realized through the cooperation of fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com