Refining technique method in malt amylin production process

A technology of production process and process method, which is applied in the field of maltodextrin production, can solve problems such as whiteness, peculiar smell, ash content and other indicators that cannot meet the requirements of users, and achieve the effect of improving product odor and increasing benefits

Active Publication Date: 2009-03-11

XIWANG GROUP

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The existing dextrin products are mainly produced according to the national standard product standards, and the production process is also controlled to meet the national standard requirements. However, with the improvement of quality requirements of food and beverage users, the whiteness of the original product standards , odor, ash and other indicators can not meet the requirements of users, the need to further improve the quality requirements of the product

Method used

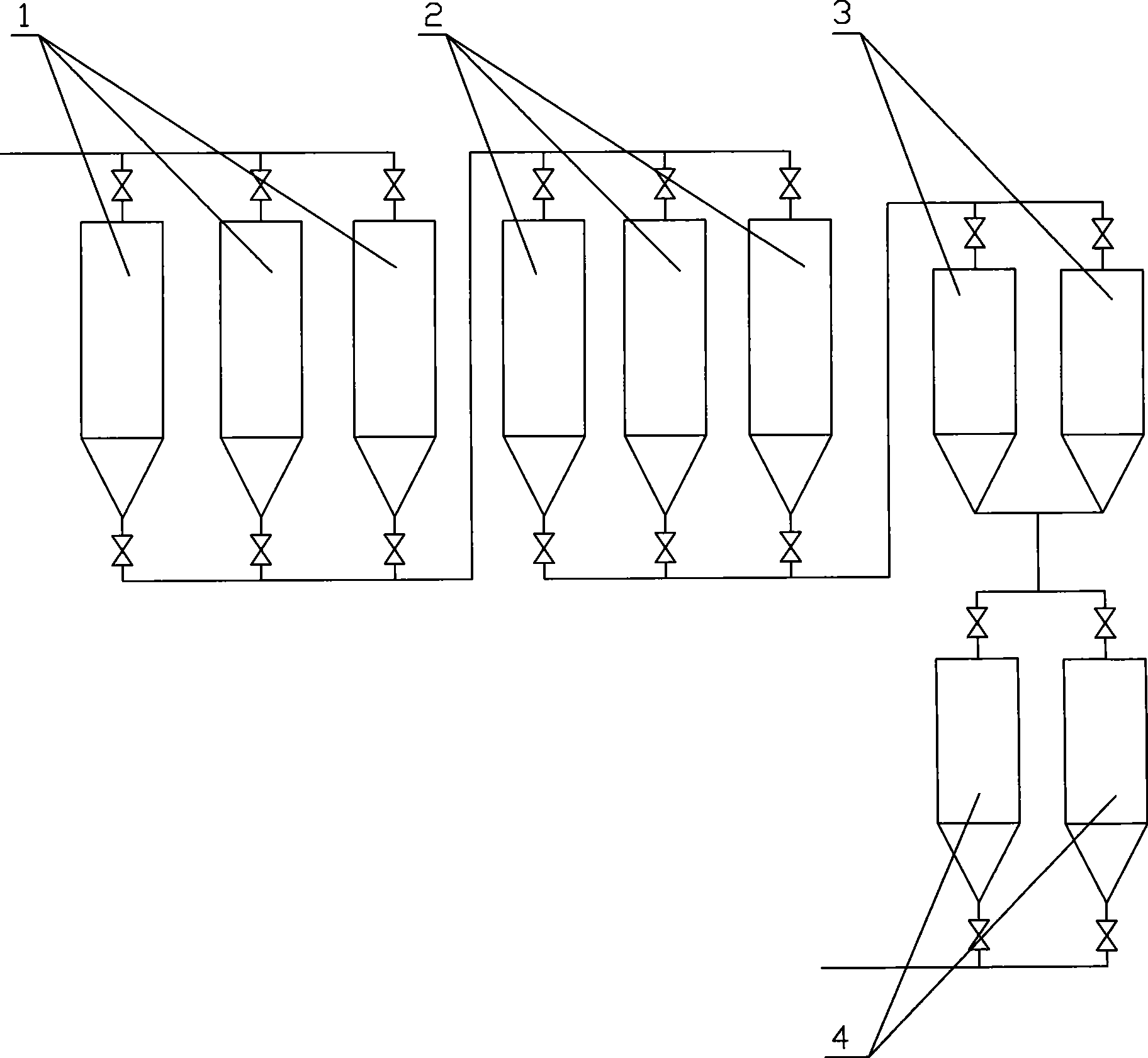

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

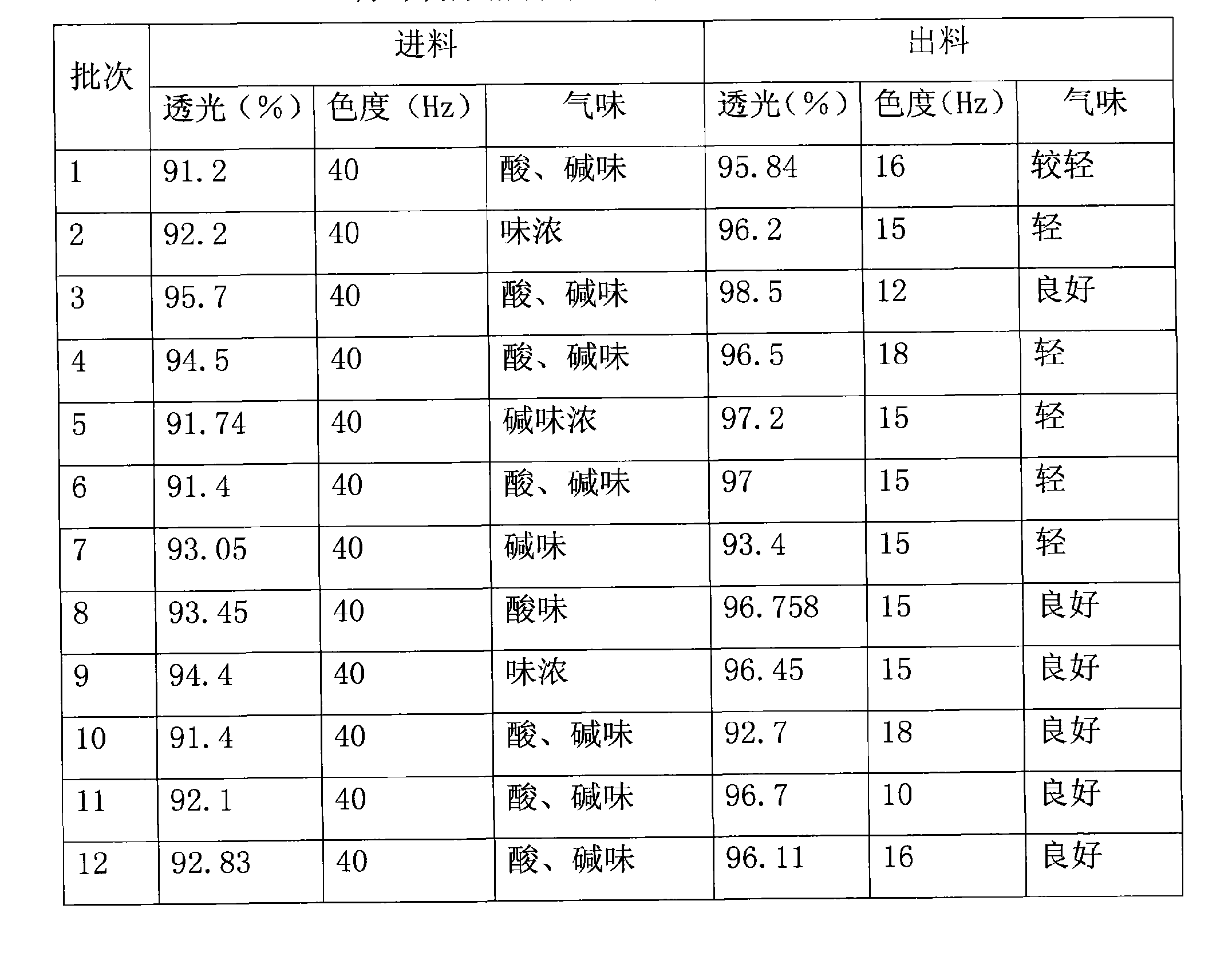

[0048] The test results of 12 batches of feed liquids refined using ion exchange and adsorption resin refining system and refining process operating method of the present invention are disclosed as follows:

[0049] Effect comparison table before and after refining with deodorizing resin:

[0050]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a refining process method for the productionof maltodextrin. The technical proposal of the method is as follows: the prior ion exchange refining system is adjusted, and a macroporous nonpolar adsorption resin column is added behind an adjustment column to form an ion exchange and adsorption resin refining system; a decolorized sugar solution directly enters the adsorption resin column through an ion exchange column for further removal of impurities and peculiar smell, and then is sent to a concentration and drying system to be processed into a dextrine product. The light transmittance of the sugar solution treated by adopting the technical proposal is improved to 96.2 percent from the prior 92.2 percent, and is improved by 3. 28 percent; the chroma is improved to a value less than 15Hz from a value which is averagely less than 40Hz; the white content is improved to 92.5 percent from average 89 percent; and particularly the odor of the product is apparently improved, is reduced to a light odor or no odor from the prior strong acid and base odor and burned odor, and achieves the requirement of customers.

Description

Technical field: [0001] The invention belongs to the field of maltodextrin production and relates to a refining process of maltodextrin. Background technique: [0002] Maltodextrin is one of the deep-processing products of starch. It is a product between starch and starch sugar obtained by controlled low-level enzymatic hydrolysis from starch slurry. Maltodextrin is widely used in candies, beverages, In food, medicine, cosmetics and other industries, it can also be used as a dispersant and stabilizer in other industrial production processes. [0003] The existing dextrin products are mainly produced according to the national standard product standards, and the production process is also controlled to meet the national standard requirements. However, with the improvement of quality requirements of food and beverage users, the whiteness of the original product standards , odor, ash and other indicators can not meet the requirements of users, the need to further improve the qu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08B30/18

Inventor 王勇王金明王岩王金波王云王非何玉梅

Owner XIWANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com