CdGeAs2 crystal etching agent and etching method

A kind of etchant and crystal technology, applied in the direction of crystal growth, chemical instruments and methods, preparation of test samples, etc., can solve the problem that the etching pit pattern is not clear enough, the three-dimensional etching pit morphology image cannot be seen, and the corrosion research of CdGeAs2 crystal has not been seen. Reporting and other issues, to achieve the effect of low cost, good corrosion resistance and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this example, CdGeAs 2 The etchant for the crystal is prepared from hydrochloric acid, nitric acid and deionized water, the mass concentration of the hydrochloric acid is 35-38%, and the mass concentration of the nitric acid is 65-68%. The volume ratio of hydrochloric acid, nitric acid, deionized water is hydrochloric acid: nitric acid: deionized water=1:1:1, measure hydrochloric acid, nitric acid and deionized water respectively by described volume ratio, then hydrochloric acid, nitric acid are added deionized water and Stir evenly to form a corrosive agent.

Embodiment 2

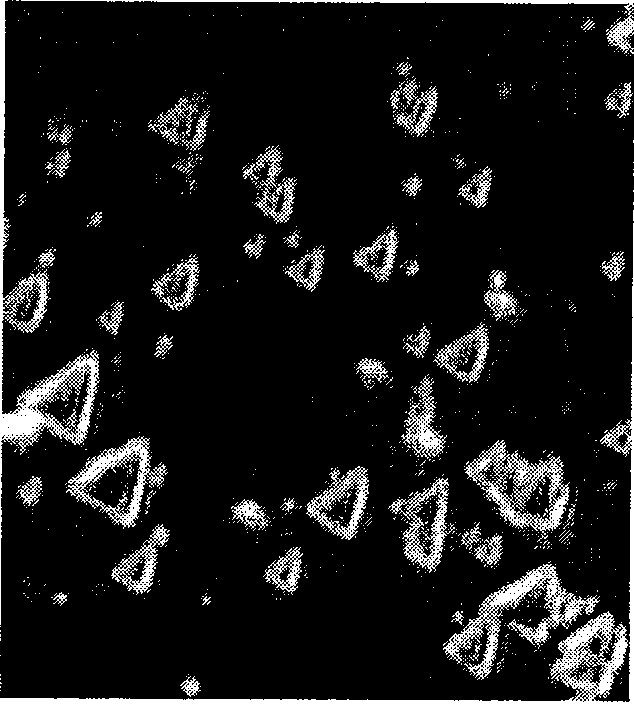

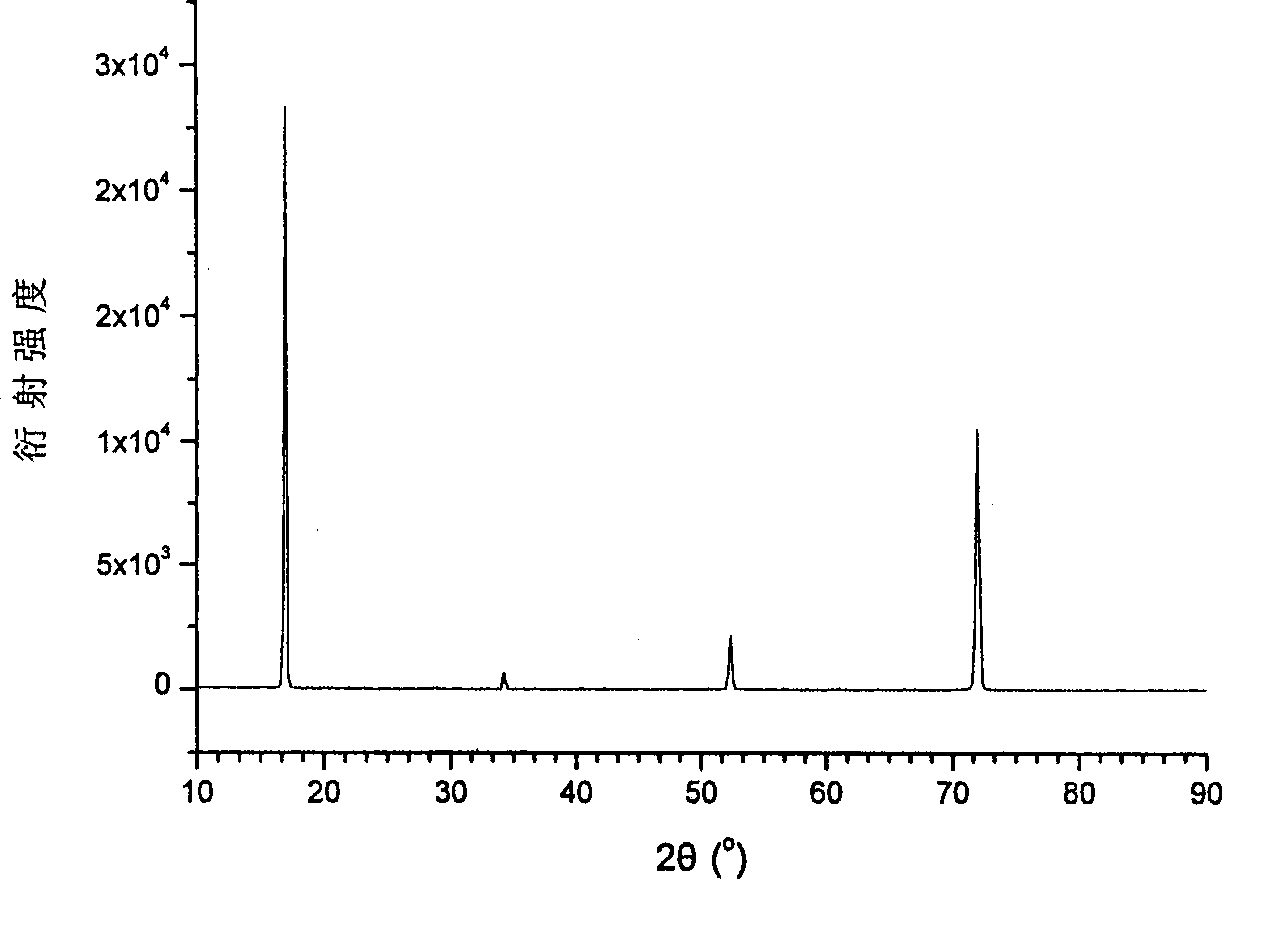

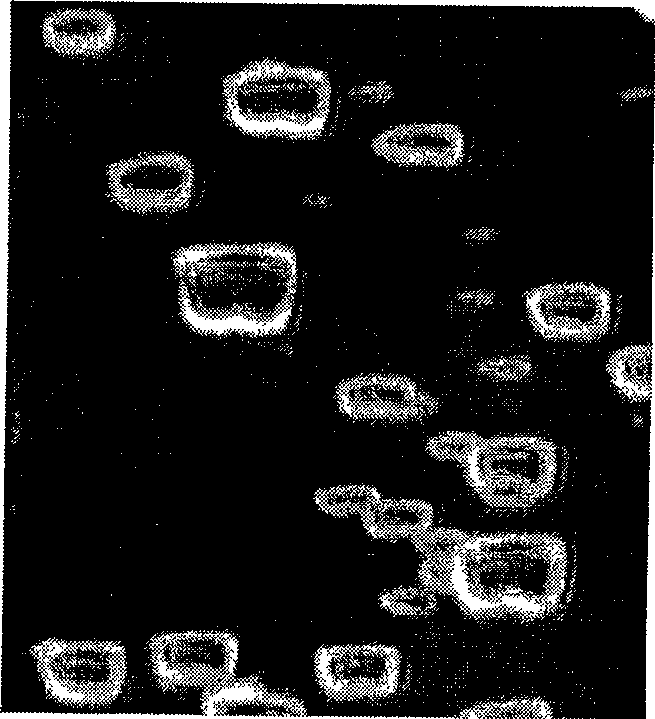

[0028] In this example, CdGeAs 2 The (101) crystal face of the crystal is etched, and the etchant used is the etchant prepared in Example 1, and the process steps are as follows:

[0029] (1) Grinding and polishing

[0030] CdGeAs 2 The crystal (101) wafer is roughly ground and finely ground with 0#-02#-04#-06# metallographic sandpaper with an average particle size distribution of 50 μm to 5 μm, and then white corundum powder (average particle size 0.5 μm) and The suspension of deionized water (the mass ratio of white corundum powder and deionized water is 1:10) was mechanically polished on silk cloth for 20 minutes, and then rinsed with deionized water to obtain CdGeAs with a smooth surface. 2 Wafer; then place the mechanically polished wafer in a bromomethanol solution with a mass concentration of 3%, soak it at room temperature for about 1 minute for chemical polishing, and clean it with methanol, acetone, ethanol and deionized water in sequence after taking it out;

[0...

Embodiment 3

[0039] In this example, CdGeAs 2 The etchant for the crystal is prepared from hydrochloric acid, nitric acid and distilled water, the mass concentration of the hydrochloric acid is 35-38%, and the mass concentration of the nitric acid is 65-68%. The volume ratio of hydrochloric acid, nitric acid, distilled water is hydrochloric acid: nitric acid: distilled water=1:1:1, measure hydrochloric acid, nitric acid and distilled water respectively by said volume ratio, then add hydrochloric acid, nitric acid to distilled water and stir to form corrosive agent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap