Continuously variable transmission control device, continuously variable transmission, and vehicle equipped with the same

A continuously variable transmission and control device technology, applied in the direction of transmission, toothed elements, transmission control, etc., can solve the problems of poor riding experience, uneven acceleration, etc., to avoid the reduction of driving comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0065]

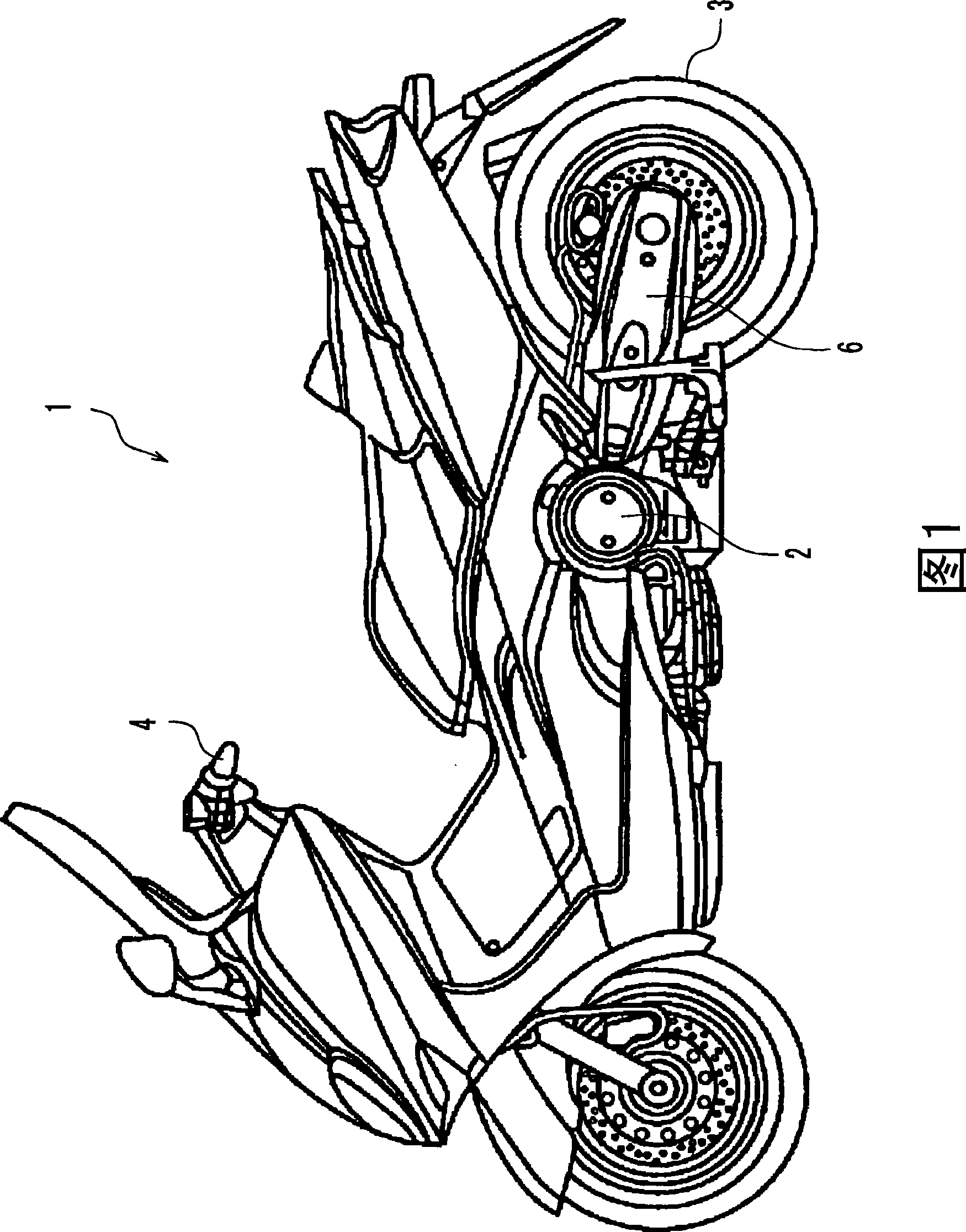

[0066] In this embodiment, a scooter type motorcycle 1 will be explained as an example of an embodiment of the present invention. As shown in FIG. 1, a motorcycle 1 includes a handlebar 4, a power unit 2, and a rear wheel 3 as a driving wheel.

[0067] (handles 4)

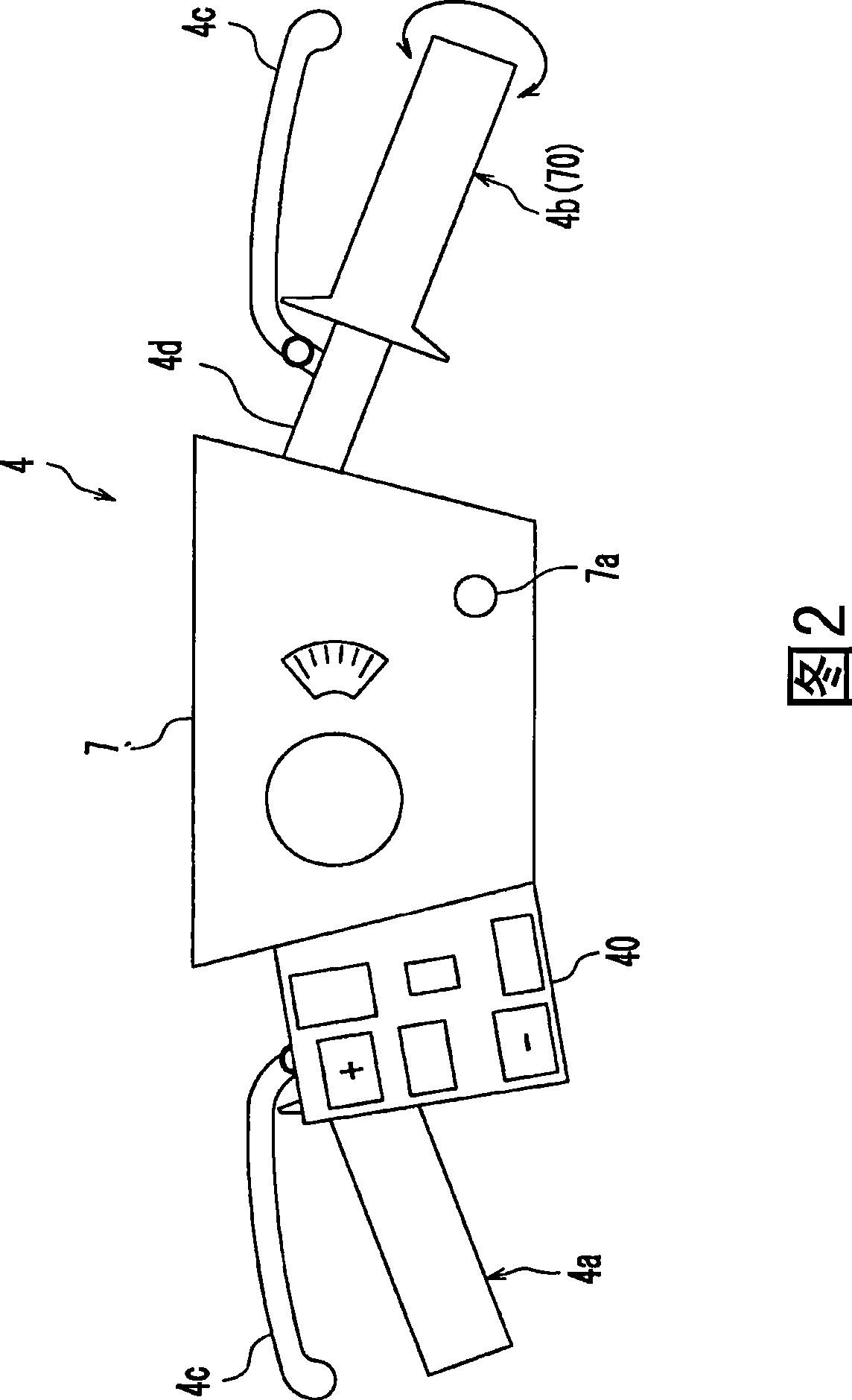

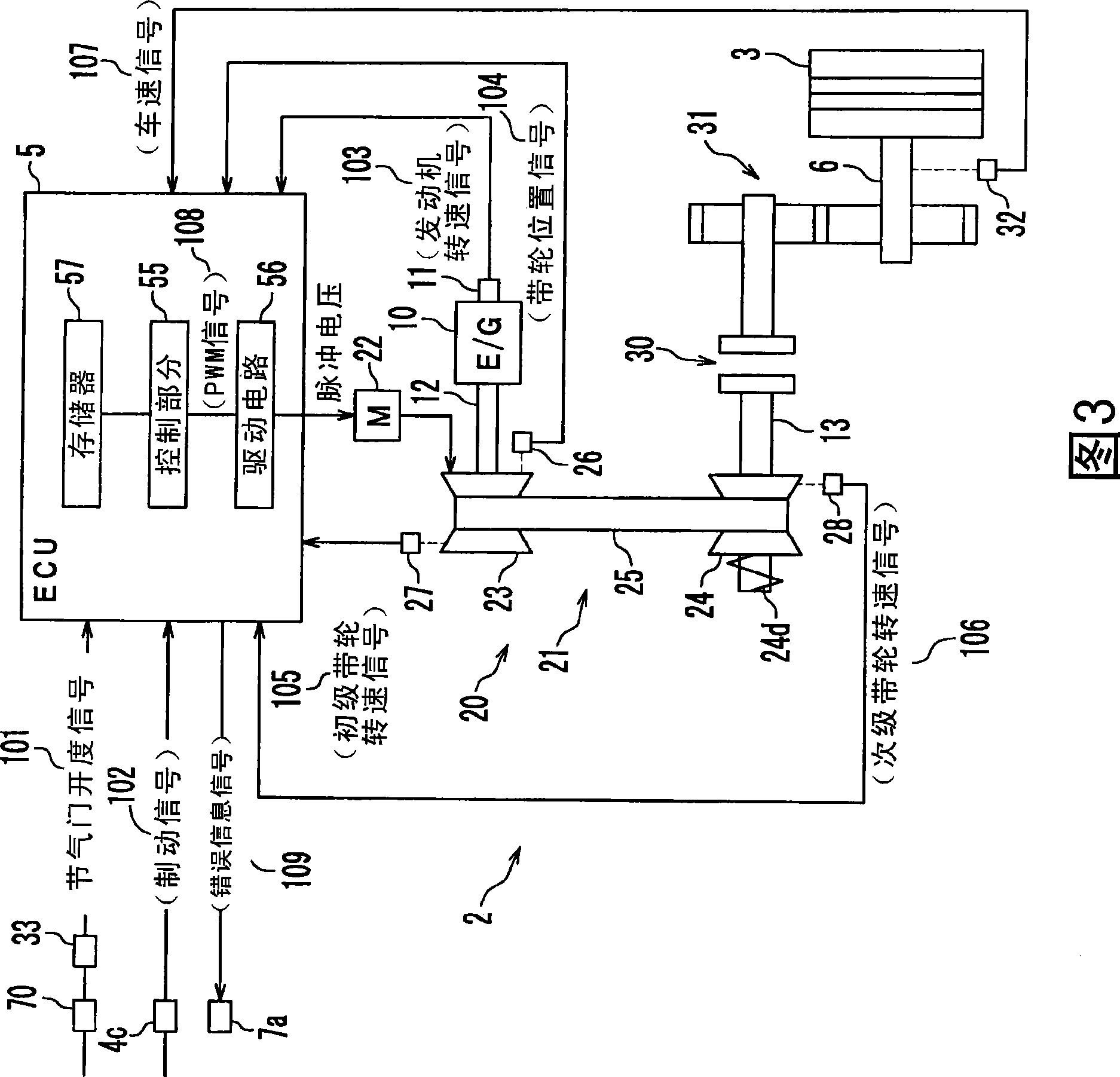

[0068] FIG. 2 shows a schematic view of the structure of the handlebar 4 . The handlebar 4 includes a handlebar stem 4d connected to a steering head pipe not shown. The handlebar 4 includes a left grip portion 4a at the left end of the handlebar stem 4d and a right grip portion 4b at the right end of the handlebar stem 4d. The right grip portion 4b is rotatable about the handlebar stem 4d. If the rider turns the right handle portion 4b, the throttle valve 70 as shown in FIG. 3 is operated and the throttle opening degree is adjusted.

[0069] A brake lever 4c is located adjacent to each of the handle portions 4a, 4b. When a rider operating these brake levers 4c operates the brakes (not shown) of the ...

no. 2 example —

[0138] FIG. 11 is a block diagram showing a continuously variable transmission 260 and a control system of a motorcycle according to the second embodiment. Also, according to the second embodiment, the transmission 260 is a belt-type ECVT. However, the belt of the transmission 260 according to the second embodiment is a so-called metal belt 264 .

[0139] According to a first embodiment, the actuator of the ECVT is the electric motor 22 (see FIG. 3 ). However, the actuator of the ECVT is not necessarily limited to the electric motor 22 . According to a second embodiment explained hereafter, the actuator of the ECVT is a hydraulic actuator.

[0140] Furthermore, as shown in FIG. 3 , the clutch according to the first embodiment is located in the transmission 20 between the output shaft 13 and the rear wheels 3 . In contrast, the clutch according to the second embodiment is a multi-plate friction clutch 265 located between the engine 10 and the input shaft 271 of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com