Dyeing heat energy recovery method

A high-temperature wastewater and low-temperature technology, applied in the field of dyeing process, can solve the problems of long process time, high energy consumption, high production cost, etc., and achieve the effect of reducing cooling system, reducing sewage discharge and shortening process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The high-temperature wastewater produced by dyeing is firstly exchanged with low-temperature clean water to form low-temperature wastewater, and then the decontamination treatment is carried out.

[0007] Decontamination treatment is to control pollution only by lifting.

[0008] The high-temperature clean hot water obtained after heat exchange can be directly used for the main dyeing vat and the auxiliary vat.

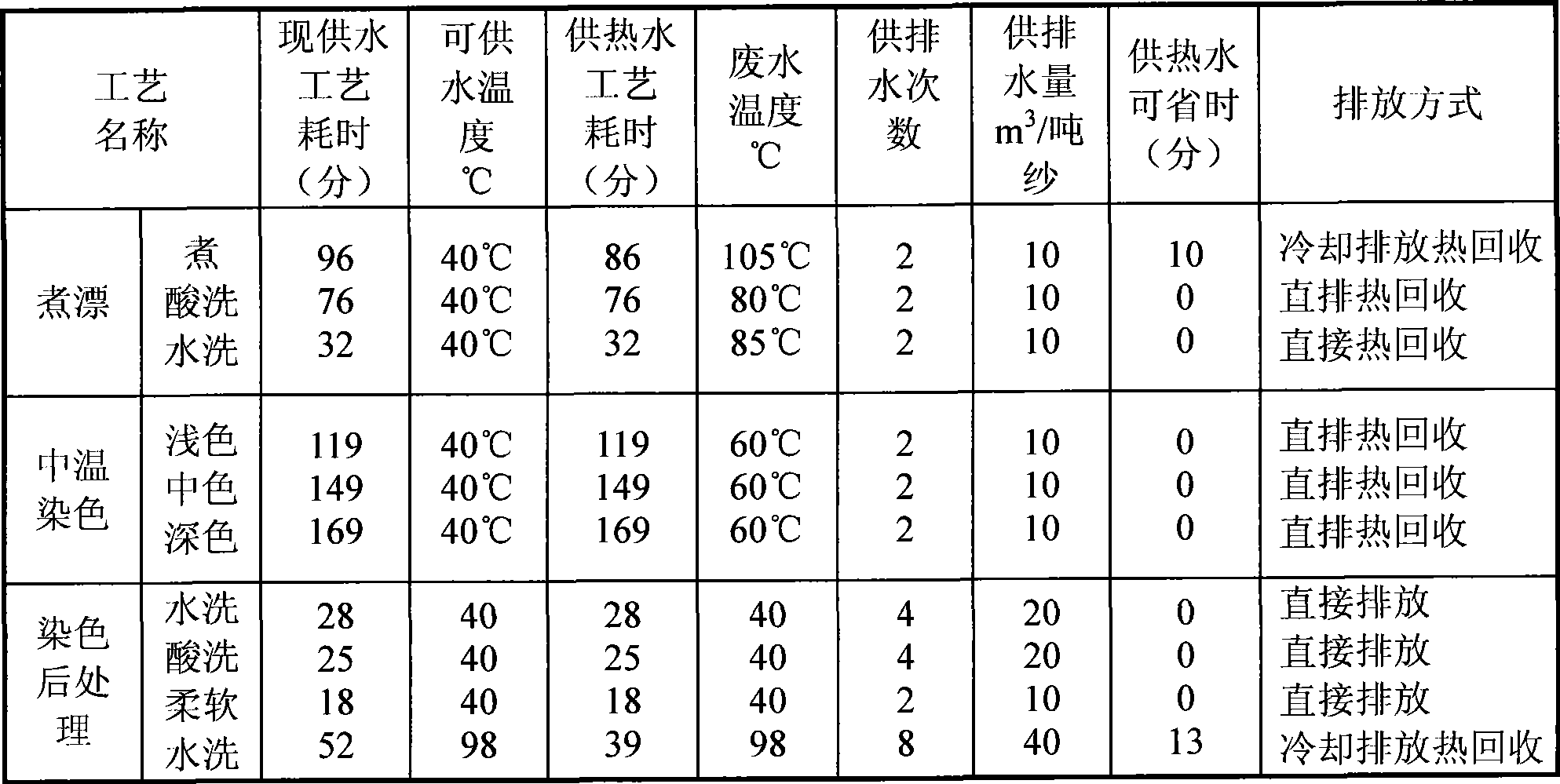

[0009] The time-consuming, supply and drainage parameters of the whole process are shown in the table below:

[0010]

[0011] Note: The whole process of the original process supplies soft water at room temperature (40°C) every time. After the technical transformation, according to the above table, the whole statistical process needs to supply hot soft water at 40°C for 9 times and 98°C for 4 times; hierarchical hot water supply can theoretically reduce the process consumption Time 23min.

[0012] illustrate:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com