Method for continuously non-interrupt numerical control processing for plate parts

A technology for processing plates and parts, which is applied in the field of continuous and uninterrupted CNC processing of plate-shaped parts, can solve the problems of easy safety accidents and affect processing efficiency, and achieve the effects of simple operation, improved cutting conditions, easy operation and programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

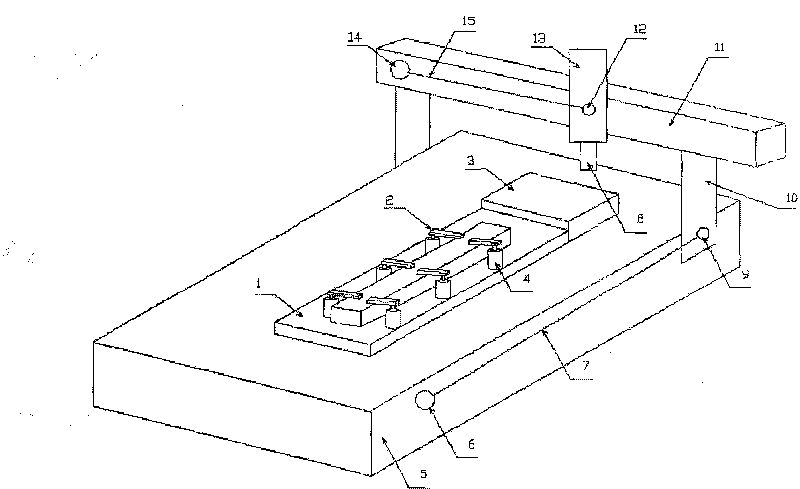

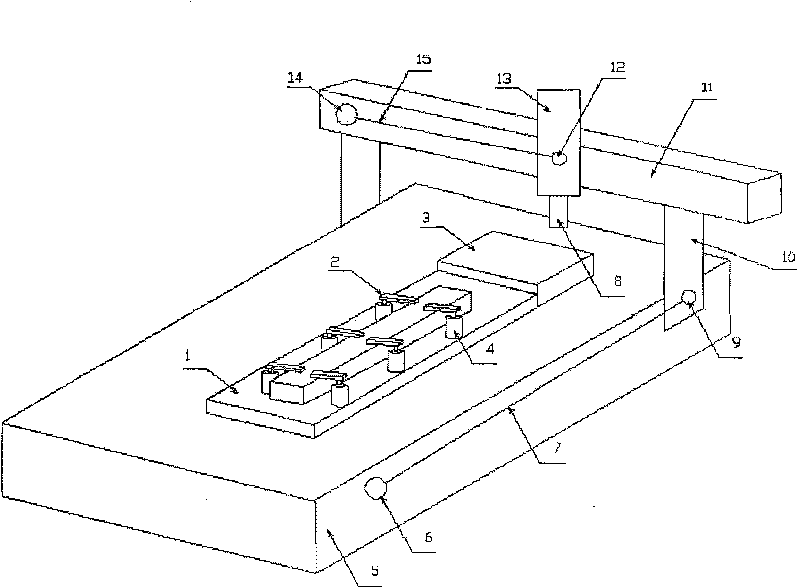

[0013] refer to figure 1 . According to the present invention, the whole control process is divided into three steps.

[0014] Step 1: Detect and track the position of the tool by the wire displacement sensor. Choose a safe location and attach the wire displacement sensor to a place where the machine tool does not move. The stay wire displacement sensors 6 and 14 are respectively adsorbed by two controllable permanent magnet bases (not shown) fixed on the side of the X-axis table 5 and on the Y-axis beam. The stay wire ends (9, 12) of the stay wire displacement sensor are respectively fixed on the moving column (10) of the X axis and the moving slide table of the Y axis. The displacement sensors (6, 14) and the stay wire ends (9, 12) are respectively connected together by the stay wires (7, 15). The controllable permanent magnet base adsorbs the two pull wire displacement sensors (6) and (14) on the X and Y axes of the numerically controlled machine tool. The control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com