Permanent magnet direct driving motor with large axial directional load

A permanent magnet direct drive, large load technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of temperature rise, slow heat dissipation, etc., to reduce temperature rise, prolong service life, ensure lubrication and heat dissipation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

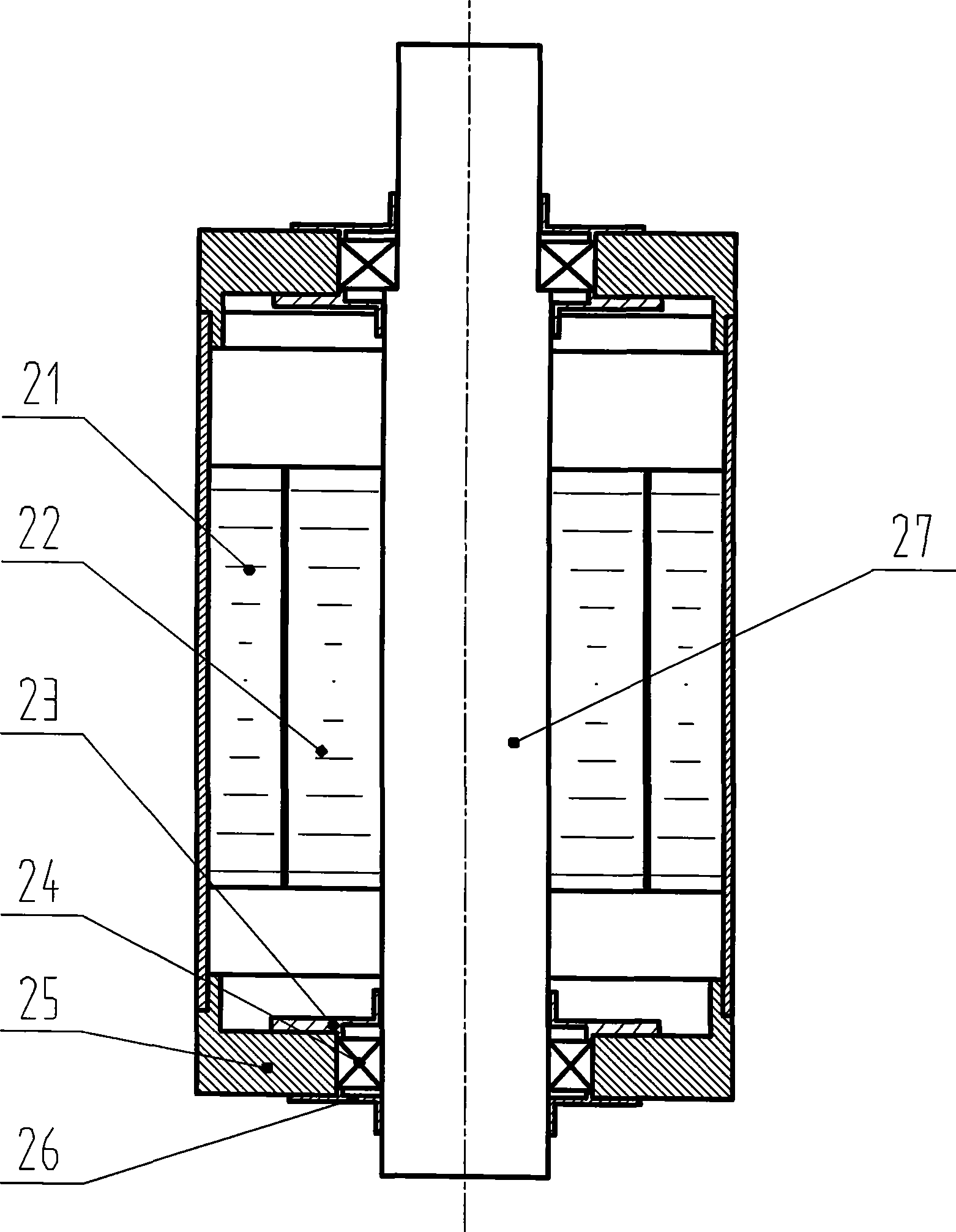

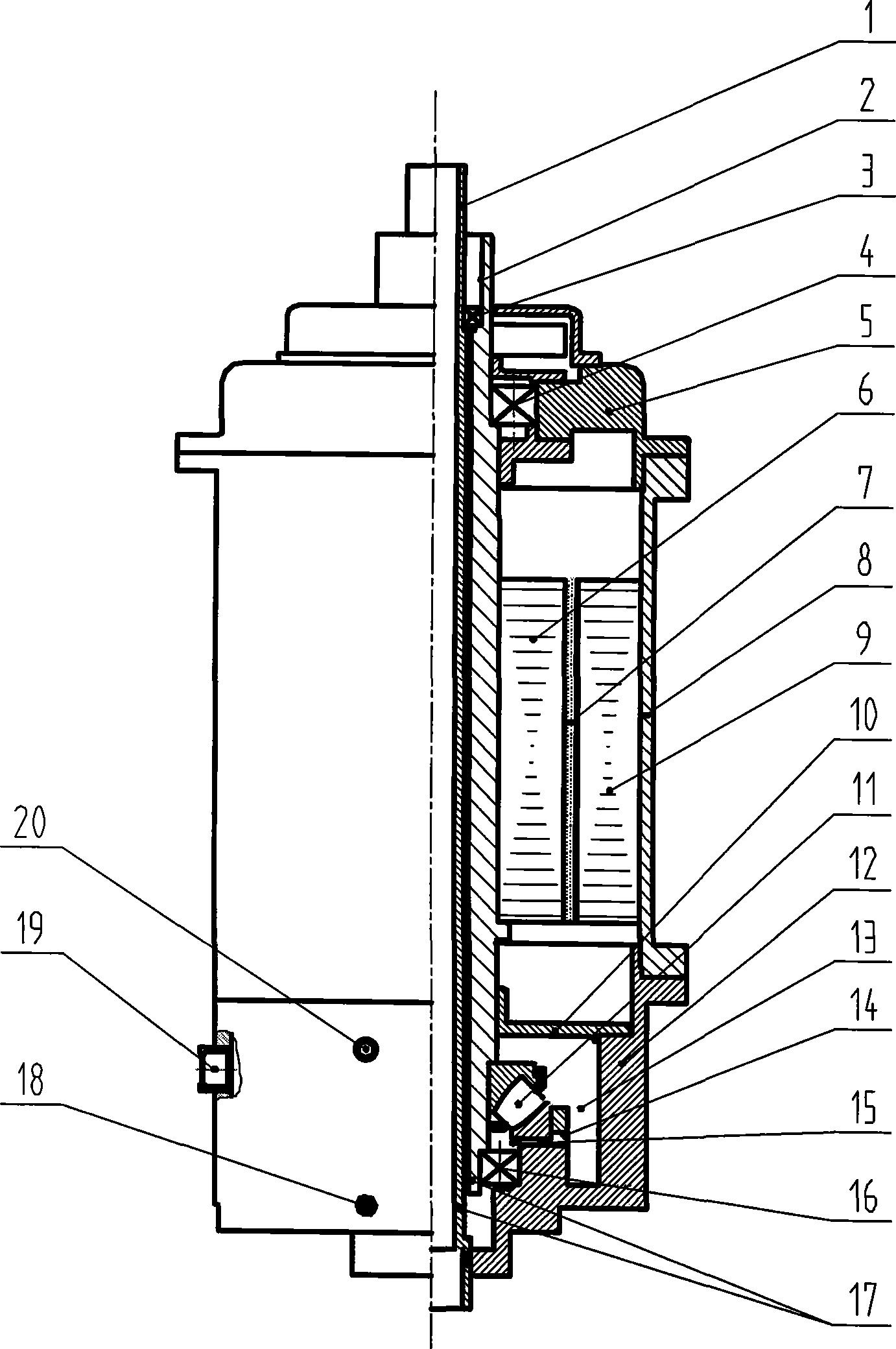

[0015] exist figure 2 Among them, the high-performance rare earth permanent magnet material-NdFeB magnet 7 is glued on the surface of the rotor 6, the rotating shaft 17 adopts a double-shaft structure, the hollow shaft is made of high-strength alloy steel, and the central shaft 1 is set in the hollow shaft 2 , the lower part is connected with the large aspect ratio end cover 12, and the sealing effect is achieved between the O-shaped sealing ring and the large aspect ratio end cover 12, the upper end of the central shaft 1 is matched with the hollow shaft 2 through the central bearing 3, and the rotor 6 are set on the hollow shaft 2, the stator 9, the rotor 6, the end cover 5, the upper support bearing 4 and the lower support bearing 16 constitute the main power part of the motor, and the spherical roller thrust bearing 11 is installed on the lower end and the large length of the hollow shaft 2 Between the bearing housings of the diameter ratio end caps 12, the large aspect r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com