Self-sealing residual compressive stress graft for dialysis

A technique of grafting and radial compression, which is applied in the direction of human tubular structure devices, blood vessels, etc., and can solve the problem of destroying the progress of hemodialysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

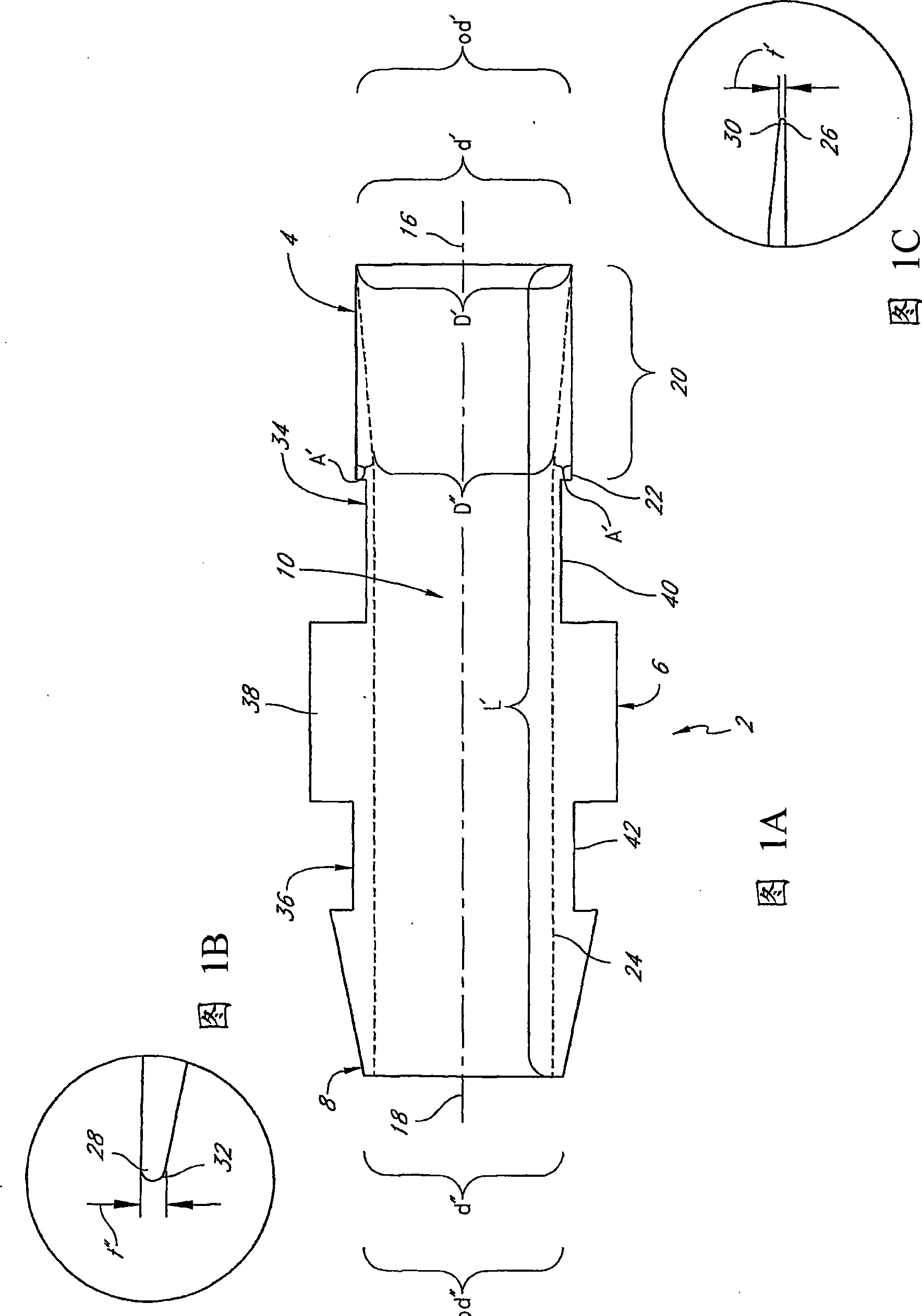

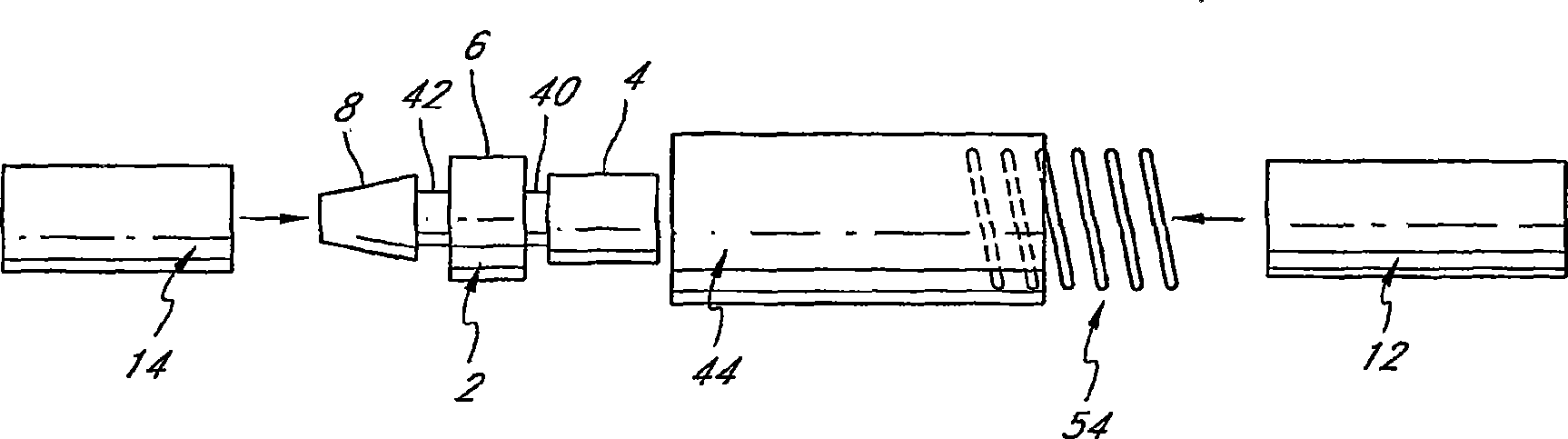

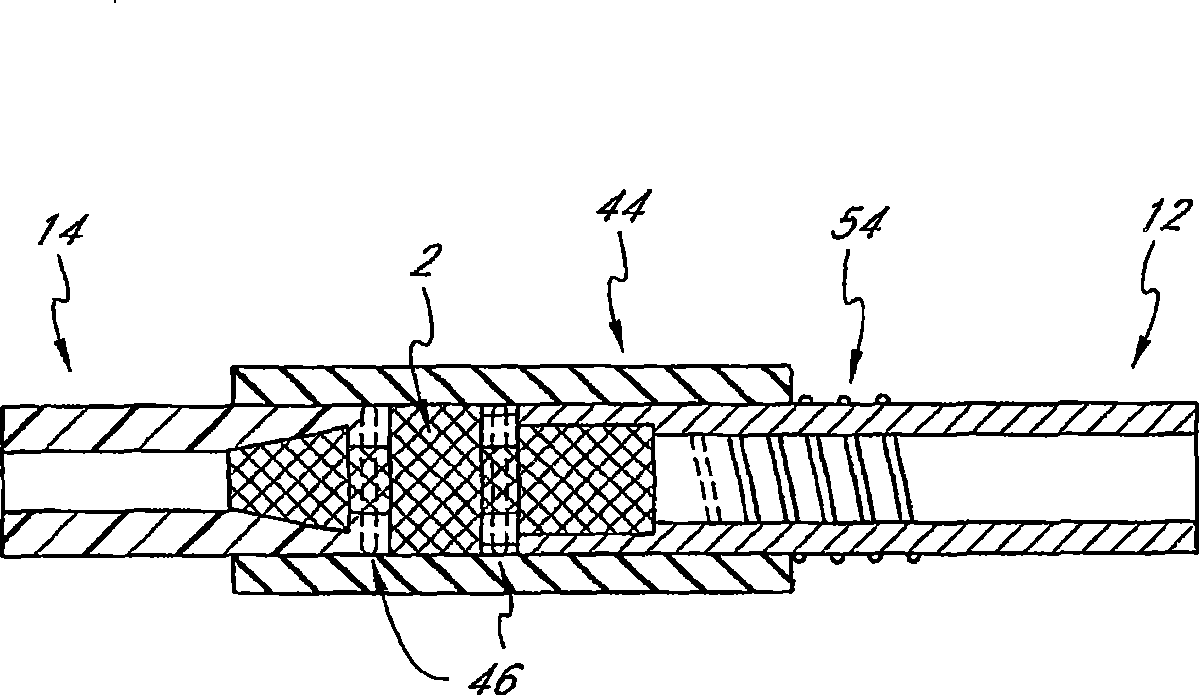

Method used

Image

Examples

Embodiment Construction

Detailed description of the preferred embodiment

[0049] Studies have shown that graft failure from local stenosis at the venous end of AV grafts is mainly due to intimal hyperplasia, compliance mismatch between graft and native vein anastomosis, and turbulent flow at the anastomotic site. Kanterman R.Y. et al"Dialysis accessgrafts: Anatomic location of venous stenosis and results of angioplasty (dialysis access grafts: anatomical location of venous stenosis and results of angioplasty)." Radiology 195: 135-139, 1995. We speculate that it can be obtained by These triggers are circumvented by using a catheter to direct blood flow into the venous system without venous anastomosis. We developed a vascular access system that removes the venous anastomosis in AV shunts using a catheter element at the venous end and a synthetic graft element that anastomoses to the artery in a standard manner. We believe such a system should eliminate or reduce venous hyperplasia, the largest cause ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com