No-weaving filter composite material of feather fiber and preparation method thereof

A feather fiber and composite material technology, applied in the field of non-woven composite materials and its preparation, can solve the problems of unfavorable fiber cohesion, hair loss, high static electricity, etc., and achieve good filtering performance and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

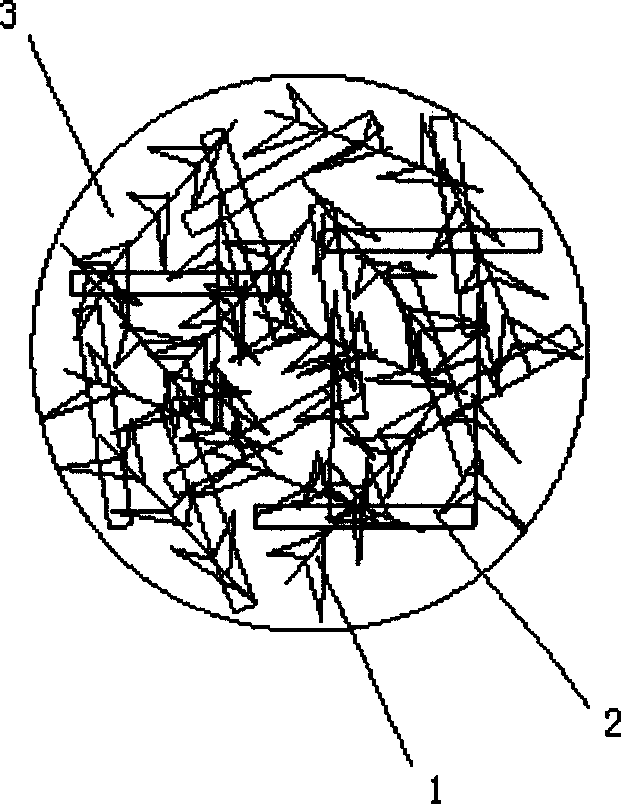

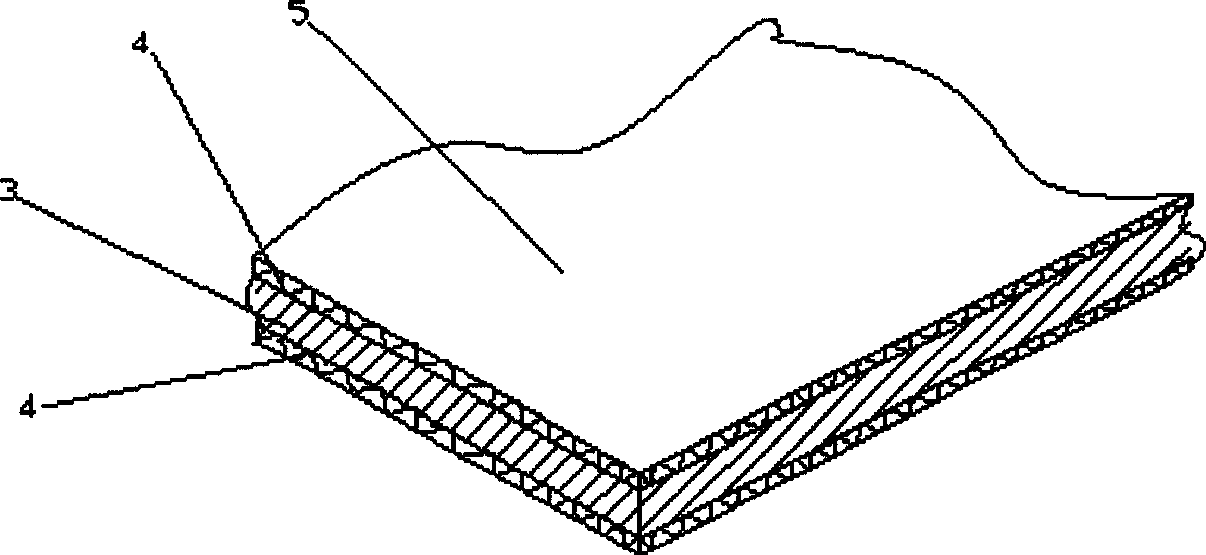

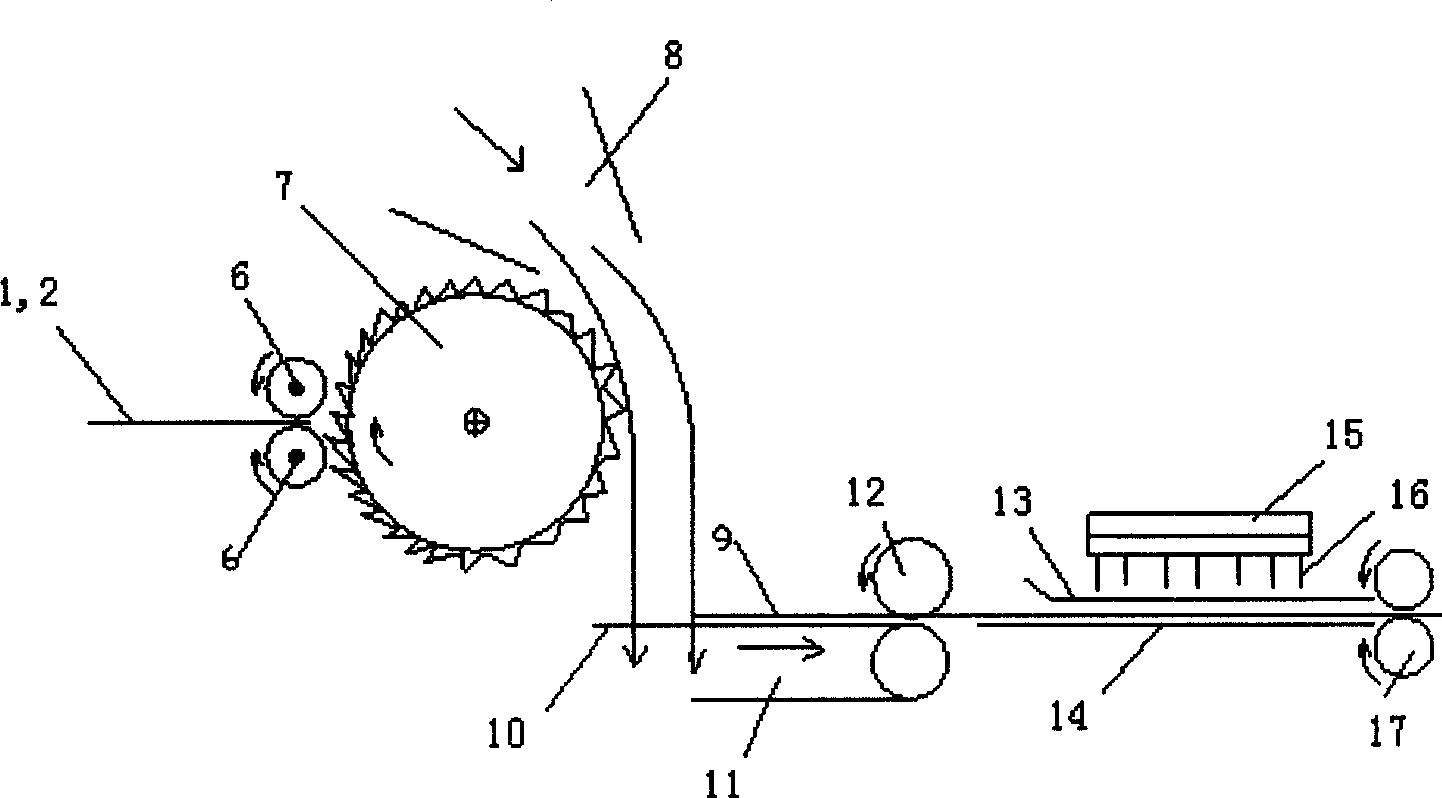

[0035] The feather nonwoven fabric is composed of feather fibers (1) and low melting point PET bicomponent fibers (2). Feather fiber (1) and low-melting point PET bi-component fiber (2) are preliminarily mixed in a mass ratio of 70:30, adjusted to humidity and added oil to remove static electricity, then opened, impurity removed, mixed, and then fed into Rando airlaid Form the fiber web, adjust the speed of the web feeding roller (6) and the web forming curtain (10) to change the fiber web density at 150-200g / m 2 between, such as image 3 . The fiber web is fed into the acupuncture machine, and the number of acupuncture passes is set to 2, such as image 3 . Then fill in the hot air oven such as Figure 4 , the hot melt temperature is 120 degrees, and the bonding time is 5 minutes. compound device such as Figure 5 , the direction of the spunbond nonwovens is the same as that of the feather nonwovens, both of which are in the same direction as the output of the machine.

Embodiment 2

[0037] The feather nonwoven fabric is composed of feather fibers (1) and low melting point PET bicomponent fibers (2). Feather (1) and low-melting-point PET bicomponent fiber (2) are preliminarily mixed in a mass ratio of 60:40, adjusted to humidity and added to remove static electricity, then opened, removed, mixed, and then fed into the Rando air-laid machine Form fiber web, adjust the speed of web feeding roller (6) and outlet web forming curtain (10) to change the fiber web density at 150-220g / m 2 between, such as image 3 . The fiber web is fed into the acupuncture machine, and the number of acupuncture passes is set to 3, such as image 3 . Then fill in the hot air oven such as Figure 4 , the hot melt temperature is 130 degrees, and the bonding time is 5 minutes. compound device such as Figure 5 , the direction of the spunbond nonwovens is the same as that of the feather nonwovens, both of which are in the same direction as the output of the machine.

Embodiment 3

[0039] The feather nonwoven fabric is composed of feather fibers (1) and low melting point PET bicomponent fibers (2). Feather (1) and low-melting-point PET bicomponent fiber (2) are preliminarily mixed in a mass ratio of 50:50, adjusted to humidity and added oil to remove static electricity, then opened, impurity removed, mixed, and then fed into the Rando air-laid machine Form the fiber web, adjust the speed of the web feeding roller (6) and the outlet web forming curtain (10) to change the fiber web density at 180-250g / m 2 between, such as image 3 . The fiber web is fed into the acupuncture machine, and the number of acupuncture passes is set to 4, such as image 3 . Then fill in the hot air oven such as Figure 4 , the hot melt temperature is 130 degrees, and the bonding time is 10 minutes. compound device such as Figure 5 , the direction of the spunbond nonwovens is the same as that of the feather nonwovens, both of which are in the same direction as the output of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com