Corrosion proof treatment method of anchor chain

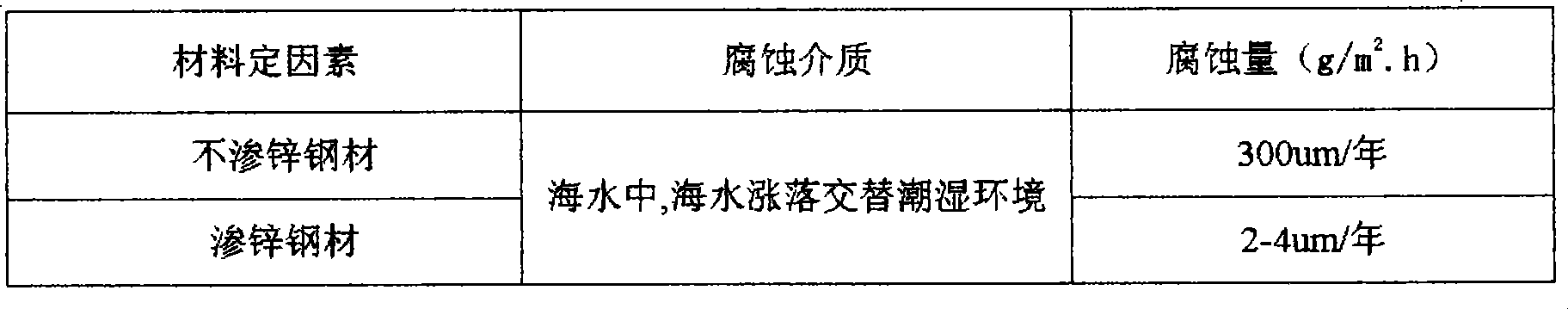

An anti-corrosion and anchor chain technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem of difficult maintenance and other problems, and achieve the effect of saving paint consumption, long service life and low average cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

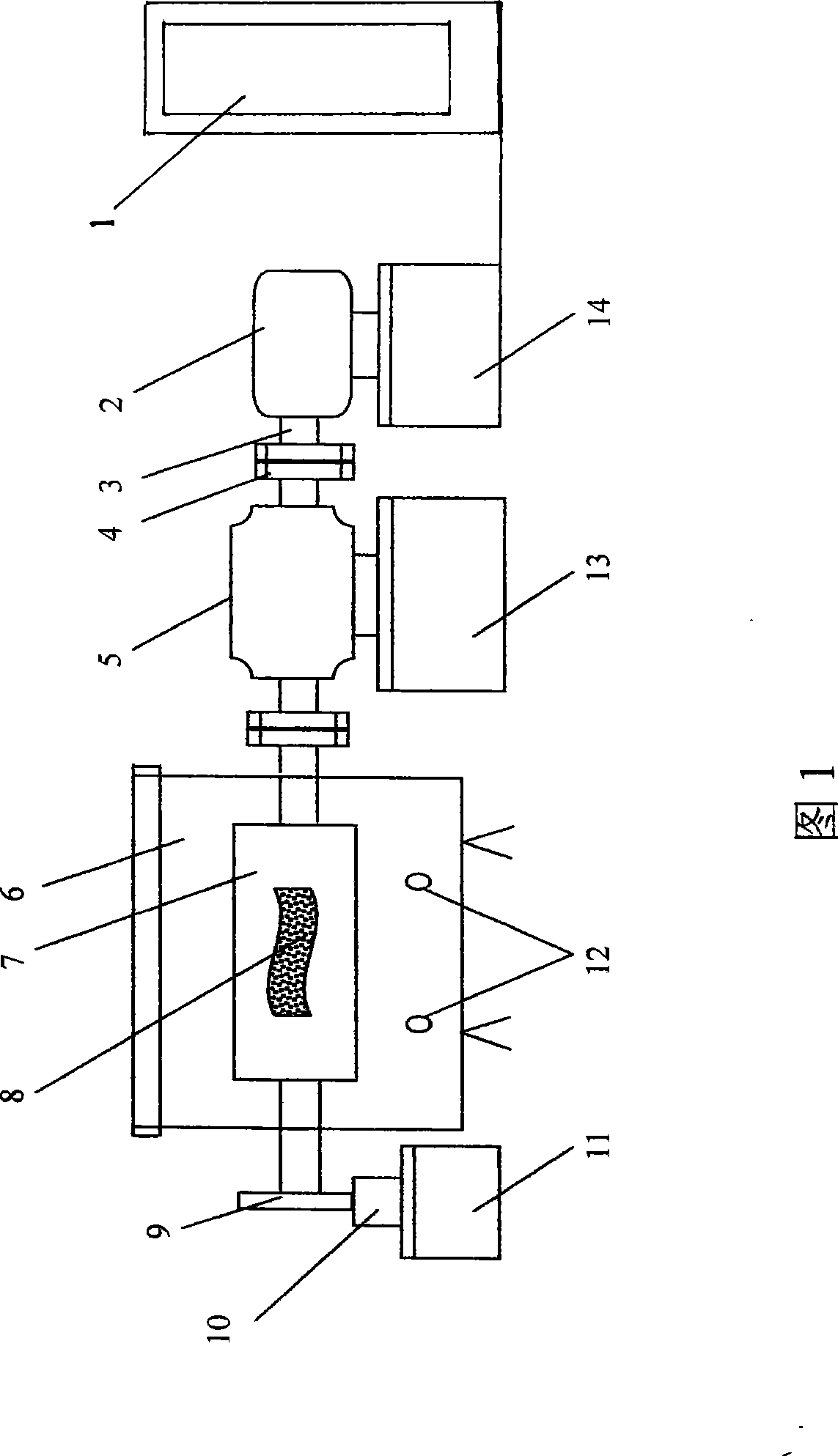

[0021] Mechanical energy assisted sherardizing is a technology that heats the component and powder sherardizing agent during mechanical movement to complete thermal diffusion and form a certain thickness of sherardizing layer on the metal surface of the component base. Permeation aid, that is, through the action of mechanical energy, changes the diffusion mechanism and reduces the activation energy of thermal diffusion, thereby helping to complete the thermal diffusion process of sherardizing. Zinc sheathing is the thermal diffusion of zinc. The speed of sherardizing is controlled by the diffusion process. During the process, the sherardizing agent continuously impacts the surface of the workpiece, and the mechanical energy generated has an activation effect on the surface of the workpiece, activating the surface lattice atoms, forming crystal defects such as vacancies, and changing The lattice diffusion is the lattice defect diffusion, so that the mechanism of mechanical energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com