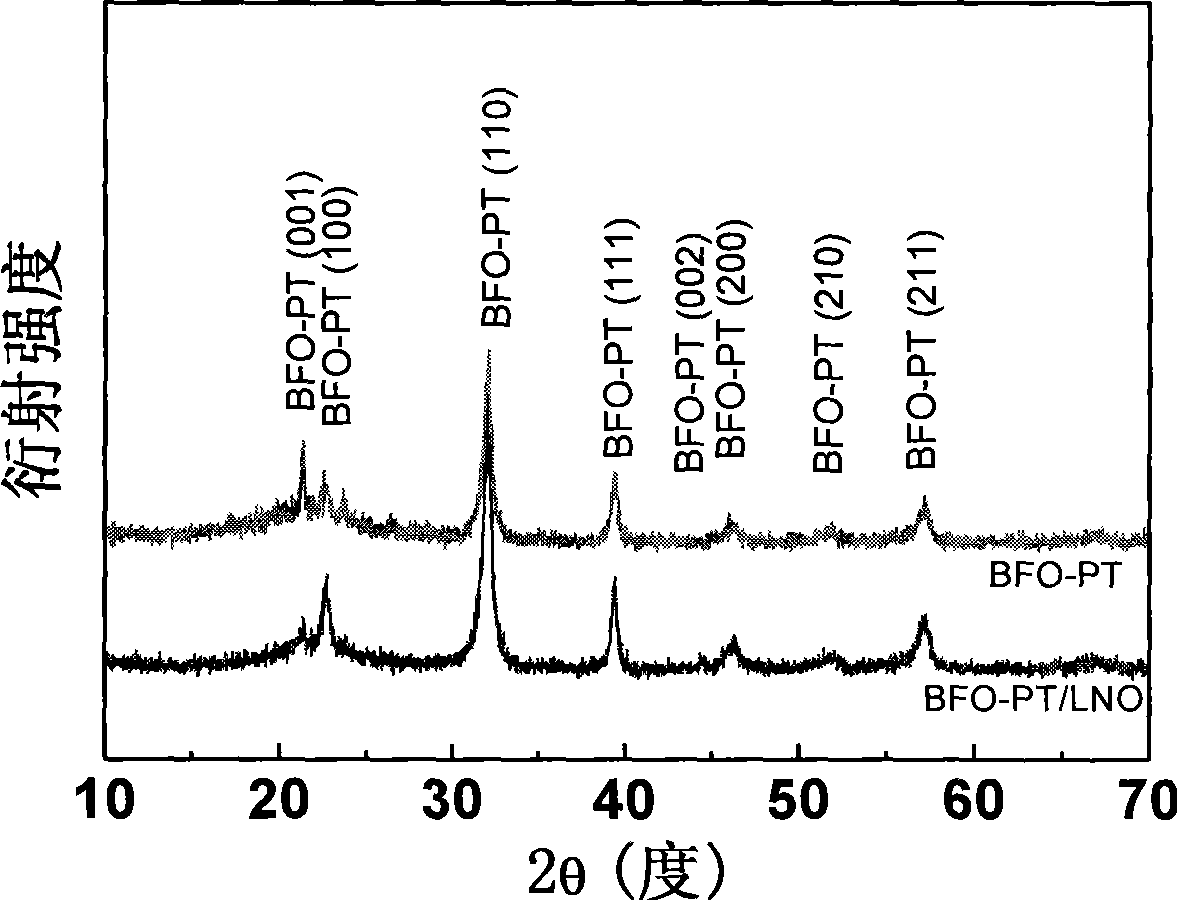

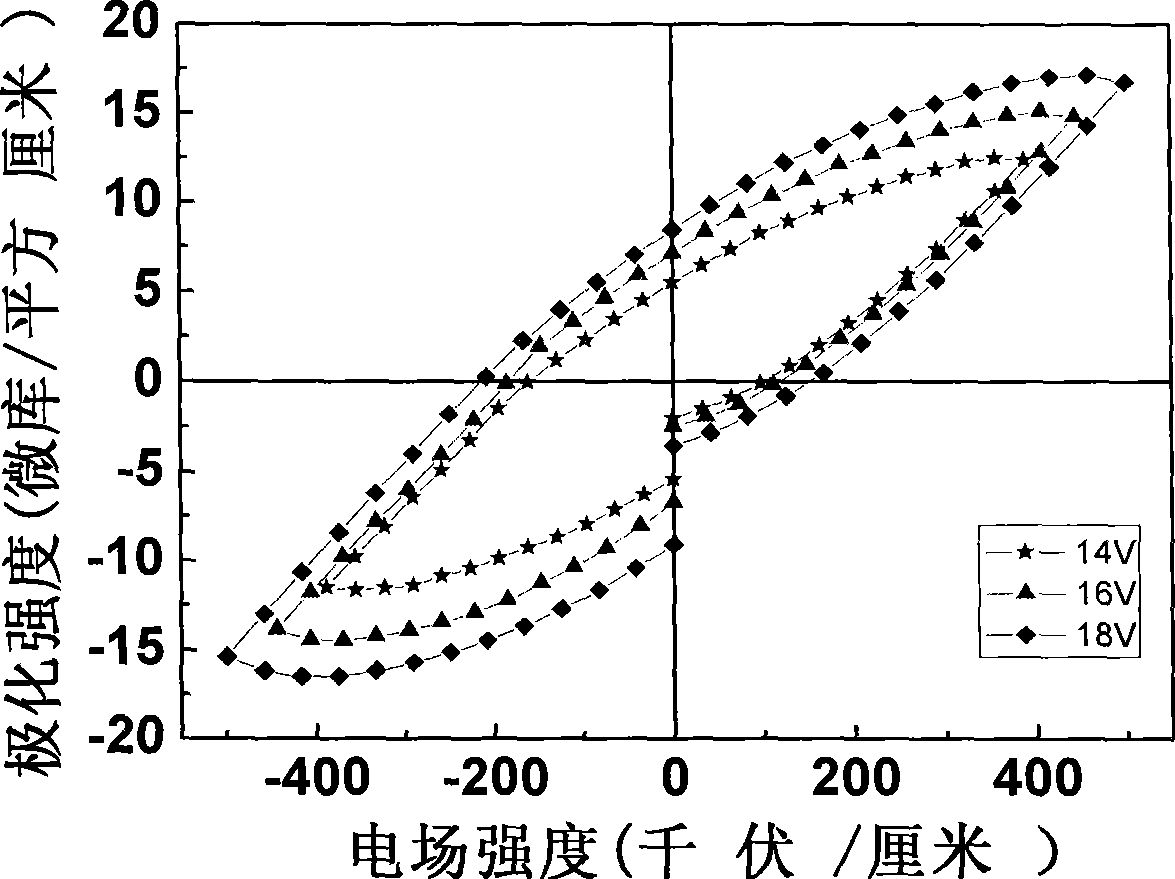

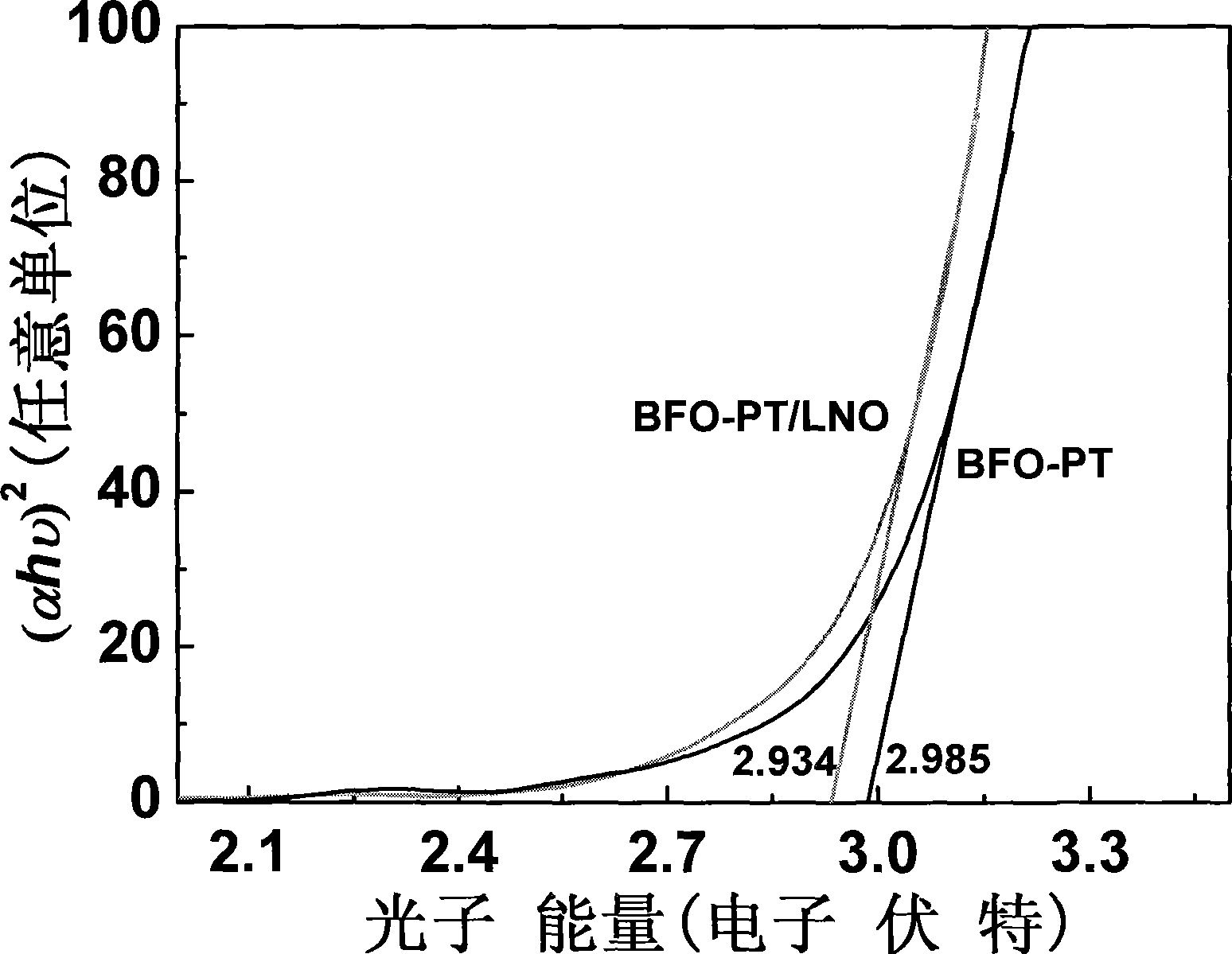

Preparation for ferroelectric material of quartz/lanthanum nickelate/bismuth ferrite-lead titanate

A three-layer structure, ferroelectric material technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as unfavorable upper-layer film crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] I. First, pre-treat the quartz glass substrate: use acetone and alcohol to ultrasonically clean it, then rinse it with deionized water, and finally bake it at 65°C for 3 hours to remove water vapor.

[0031] II. Preparation of 0.4mol / L 6BiFeO 3 -4PbTiO 3 Sol 30ml:

[0032] ① Weigh 2.0016 grams of n-tetrabutyl titanate with an analytical balance, add 5 ml of ethylene glycol methyl ether, and stir in an oil bath at 80-90 ° C for 2 to 3 hours to form a n-tetrabutyl titanate solution; weigh 2.2957 grams of lead acetate, add 13 ml of ethylene glycol The alcohol methyl ether was stirred and dissolved at room temperature, and then mixed with n-butyl titanate solution at room temperature and stirred for 30 minutes to form a lead titanate solution.

[0033] ② Weigh 4.7073 grams of bismuth nitrate pentahydrate and 3.5644 grams of iron nitrate nonahydrate, dissolve them in 6ml of ethylene glycol methyl ether respectively, and then mix and stir for 30 minutes at room temperature....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com