Organic silicon composition and application thereof

A composition and silicone technology, applied in the directions of adhesive additives, non-polymer adhesive additives, electrical components, etc., can solve the performance degradation, low shrinkage rate, inability to achieve the refractive index, weather resistance, permeability of silicone materials, etc. problems such as comprehensive improvement of light rate and mechanical properties, to achieve the effect of simple application methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

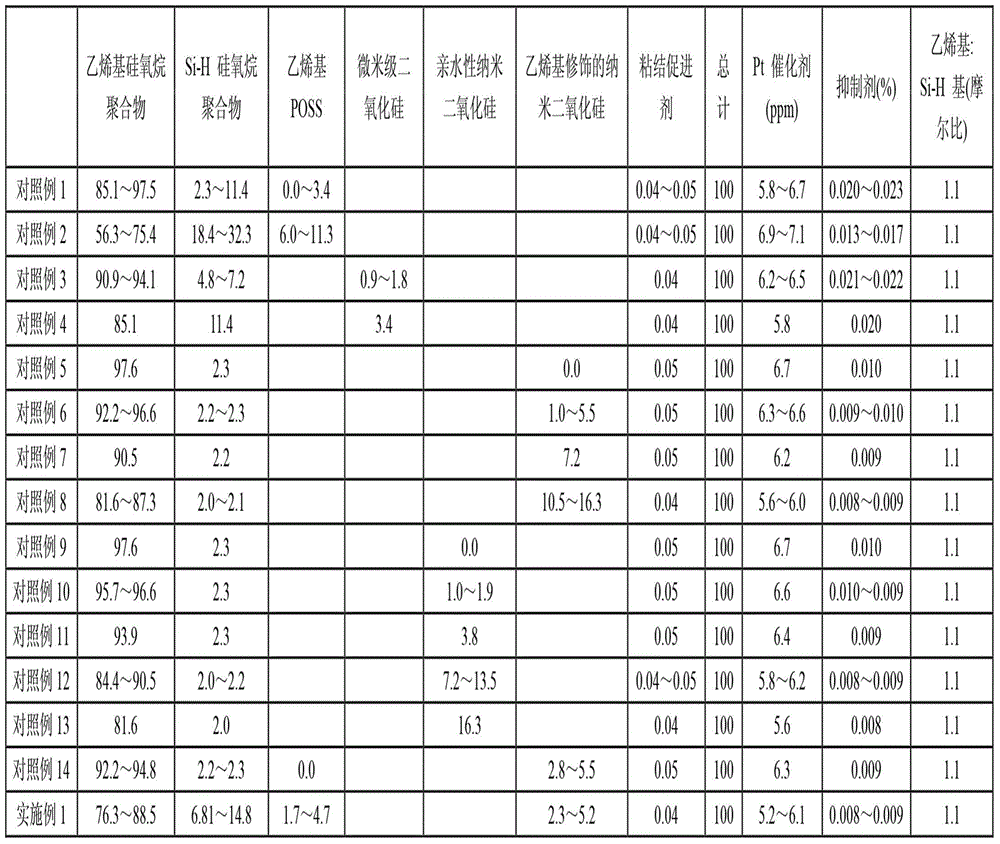

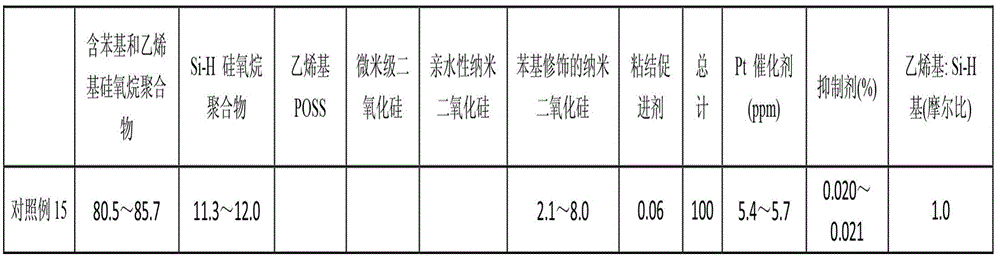

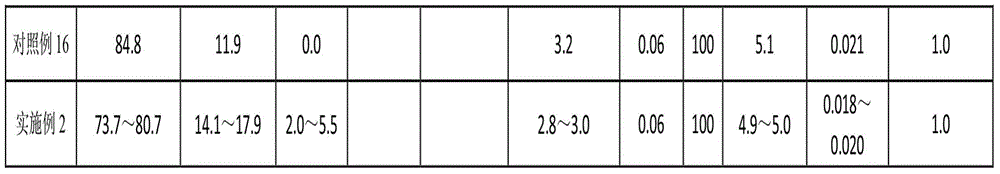

[0030] One aspect of the present invention provides a silicone composition, the base components of which include at least one vinyl siloxane polymer capable of curing by hydrosilylation reaction and at least A Si-H siloxane polymer, and at least one vinyl POSS and vinyl-or phenyl-modified nano-sized silica ).

[0031] Further, the composition may also contain a hydrosilylation curing catalyst, through which the thermal curing of the composition can be realized.

[0032] Furthermore, a hydrosilylation reaction inhibitor can also be added, and then by adjusting the type and amount of the hydrosilylation addition curing catalyst and the hydrosilylation reaction inhibitor, the curing degree and curing rate of the composition can be regulated. wait.

[0033] The aforementioned hydrosilylation addition reaction refers to the reaction of adding silicon hydrides to unsaturated organic compounds to generate various organosilicon compounds. It can be used in three ways: (1) with alken...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com