Pressure and speed regulating system for semi-digital AC stator

A technology of stator voltage regulation, speed regulation, and parameter adjustment, which is applied in the control system, AC motor control, electrical components, etc., can solve the problems of inconvenient quick finding and handling of faults, easy changes of potentiometer parameters, and unintuitive display, etc., to achieve Large deviation, reduced maintenance, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

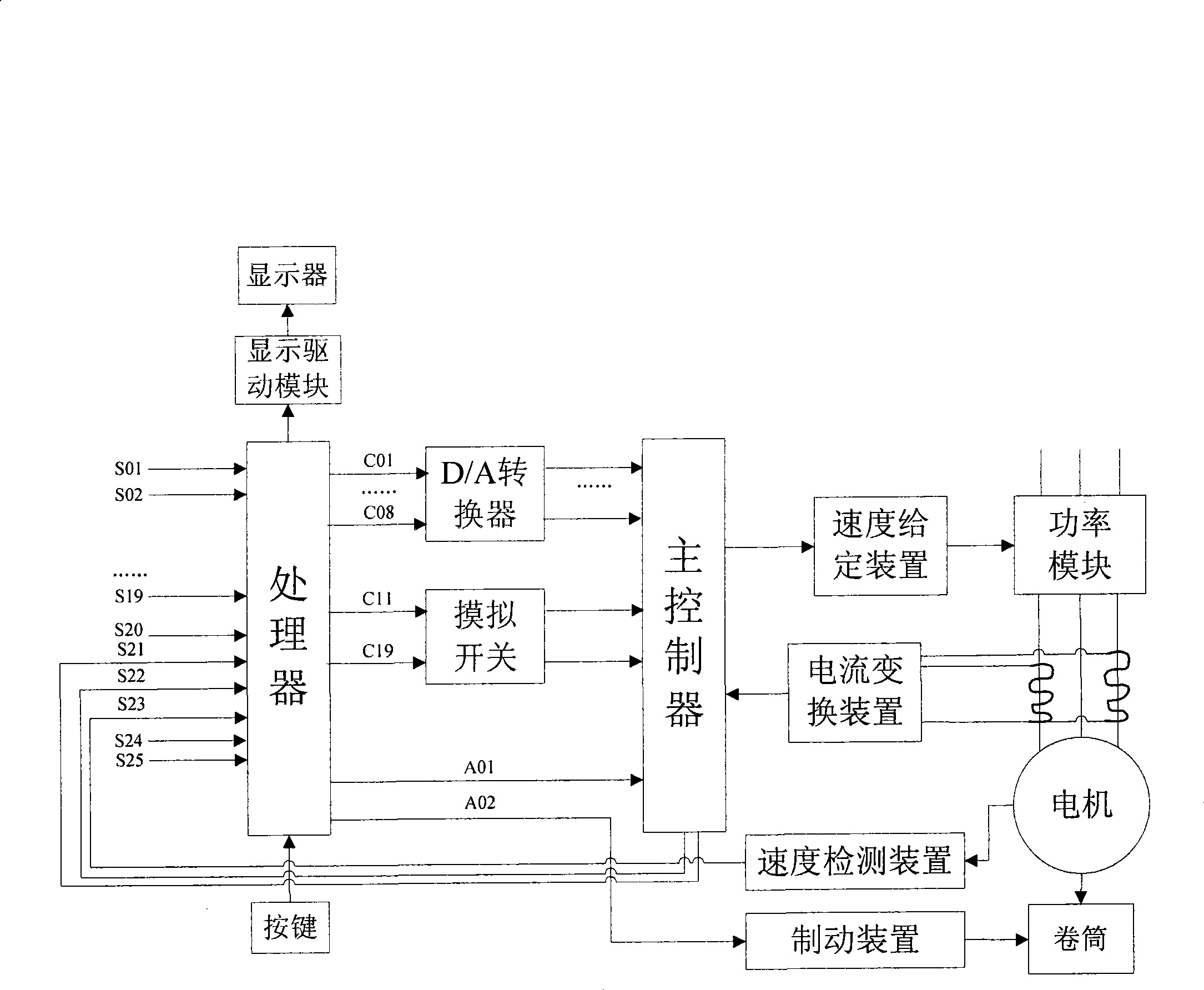

[0025] Such as figure 1 As shown, a semi-digital AC stator voltage regulation and speed regulation system includes:

[0026] main controller,

[0027] a speed setting device, connected to the main controller, for receiving a control signal from the main controller, and converting the signal into a signal for controlling the power module;

[0028] A power module, connected to the speed setting device, used to control the operation of the motor according to the signal input by the speed setting device;

[0029] A current conversion device, connected to the main controller and the induction coil on the wire at the output end of the power module, to provide a feedback signal for the main controller;

[0030] A motor is used to drive the reel to rotate;

[0031] reel,

[0032] The above-mentioned main controller, speed setting device, power module, current conversion device, motor, and reel are existing technologies, and the description of their specific control and implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com