White tea heating deterioration method and device thereof

A technology of heating withering and white tea, applied in the direction of tea treatment before extraction, can solve the problems of difficult control of temperature and humidity, and the quality of white tea cannot be guaranteed, and achieve the effect of ensuring quality and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

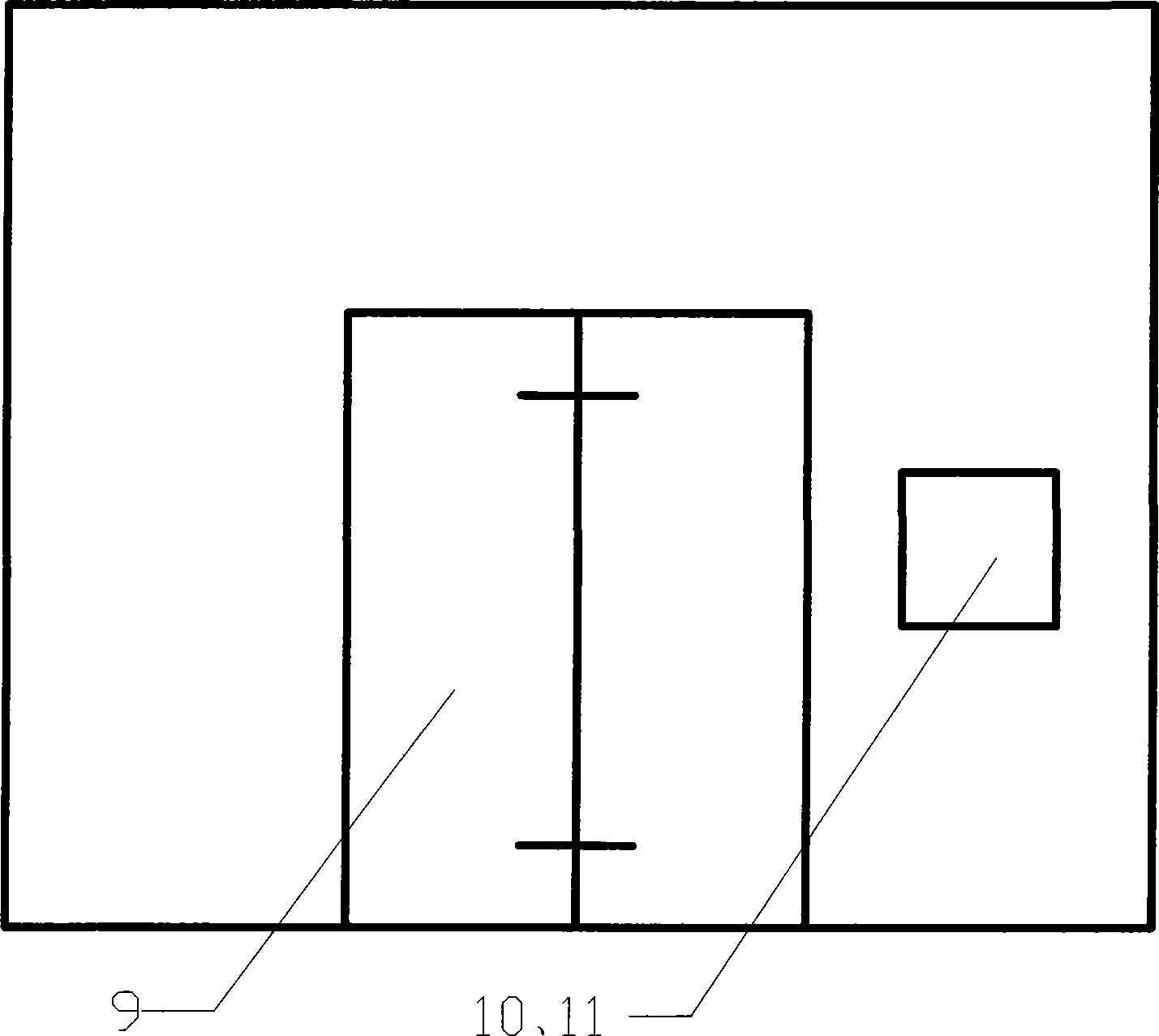

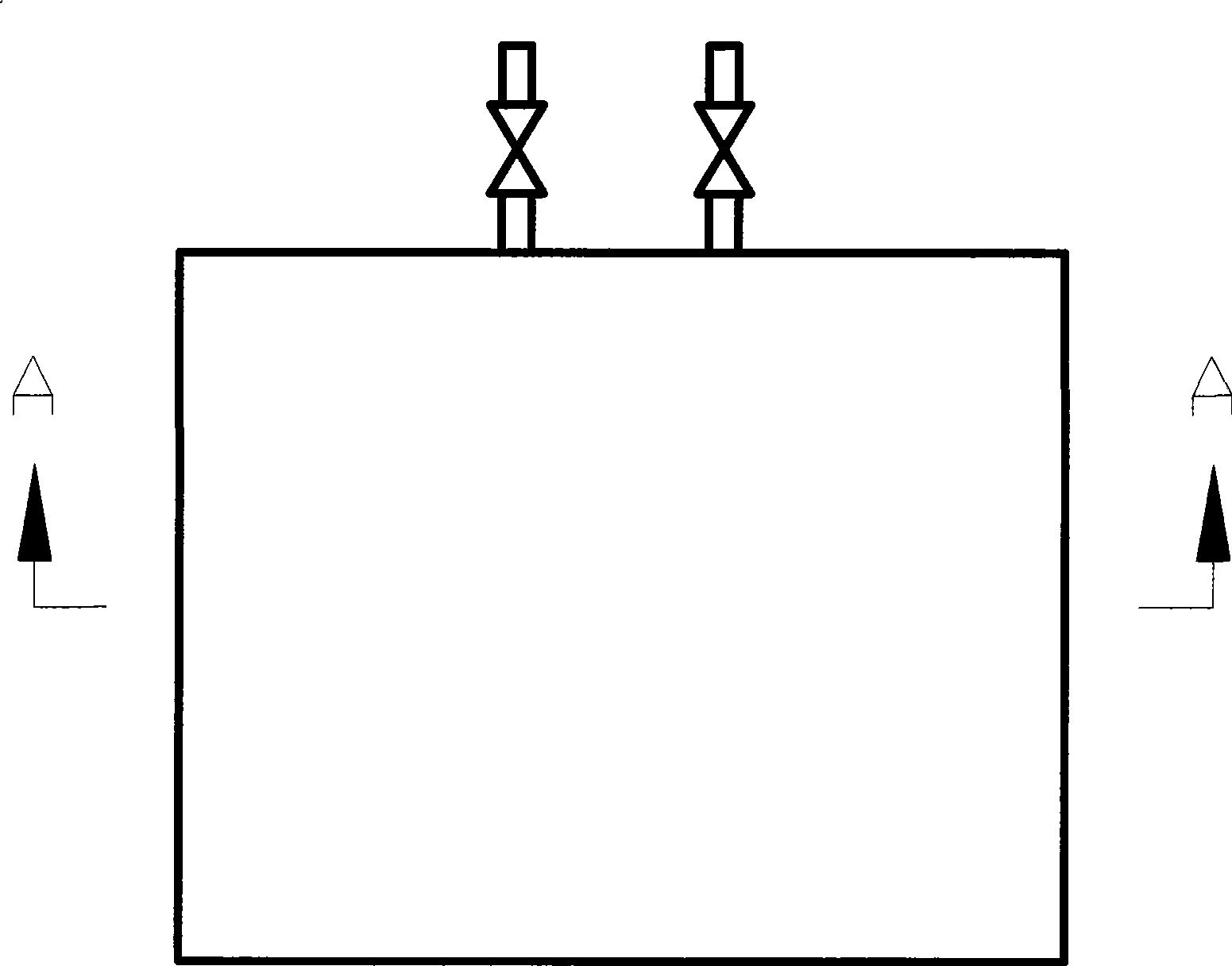

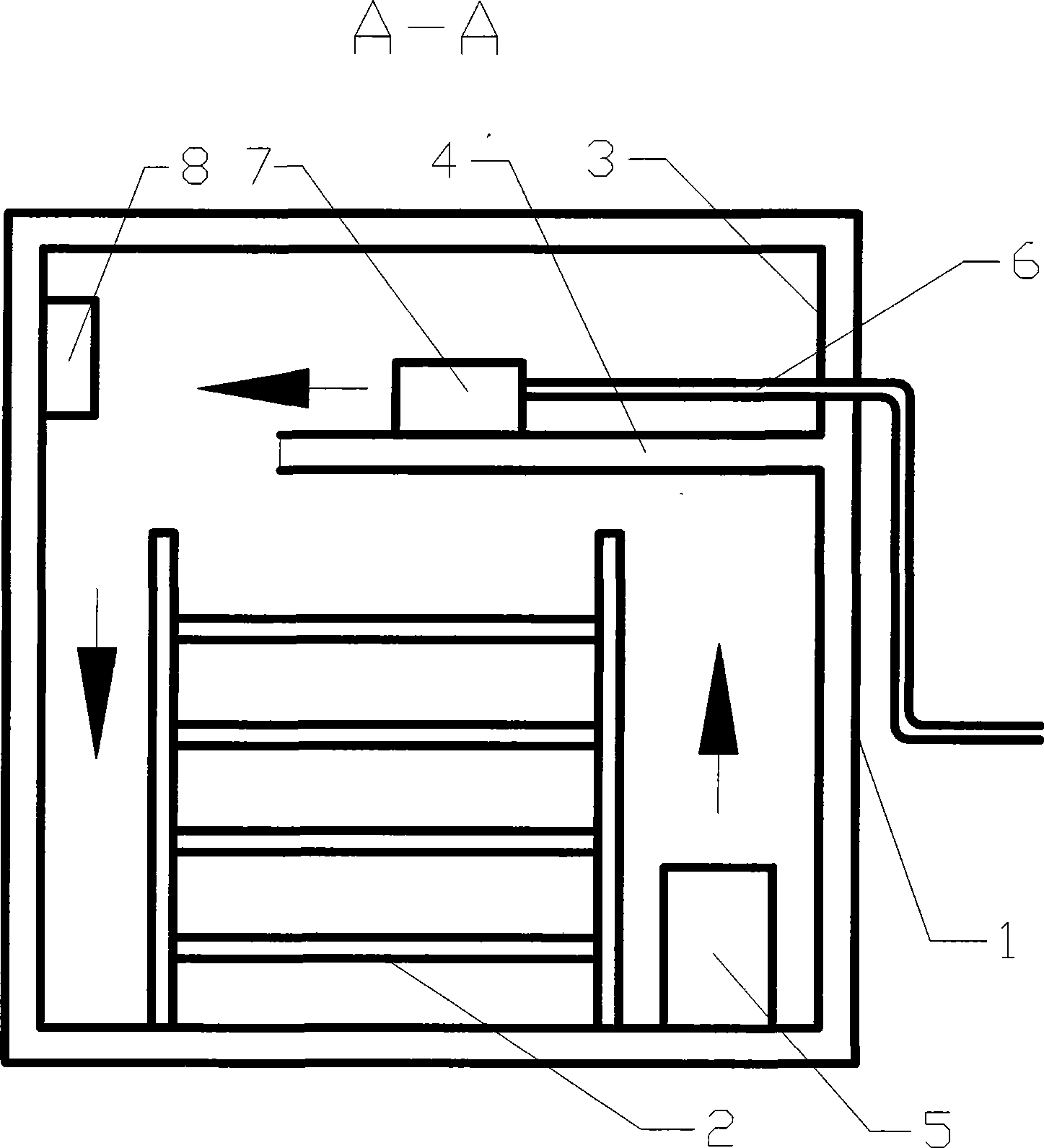

[0010] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment:

[0011] The production steps are as follows: 1) Fresh tea sieve: put fresh white tea into the sieve; 2) Fresh tea is sent to the withering greenhouse and placed in layers: the sieves with fresh white tea are placed layer by layer on the iron frame in the withering temperature control room 3) Close the withering greenhouse door; 4) Turn on the temperature controller: turn on the temperature controller on the temperature control door; 5) Turn on the humidity controller: turn on the humidity controller on the temperature control door; 6) Turn on the hot air circulation 7) open exhaust fan; 8) start fresh tea to wither: temperature 30-35 ℃, relative humidity 60%-70%, withering time 18 hours; 10) Temperature control time: the temperature is controlled at 30°C for the first 3 hours, 32°C for the middle 12 hours, and 35°C for the last 3 hours.

[0012] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com