Charging device of automatic apple peeling machine

A peeling machine, apple technology, applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of prone to errors and even accidents, labor-intensive, labor-intensive, etc., to improve the level of hygiene and reduce labor intensity. , the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

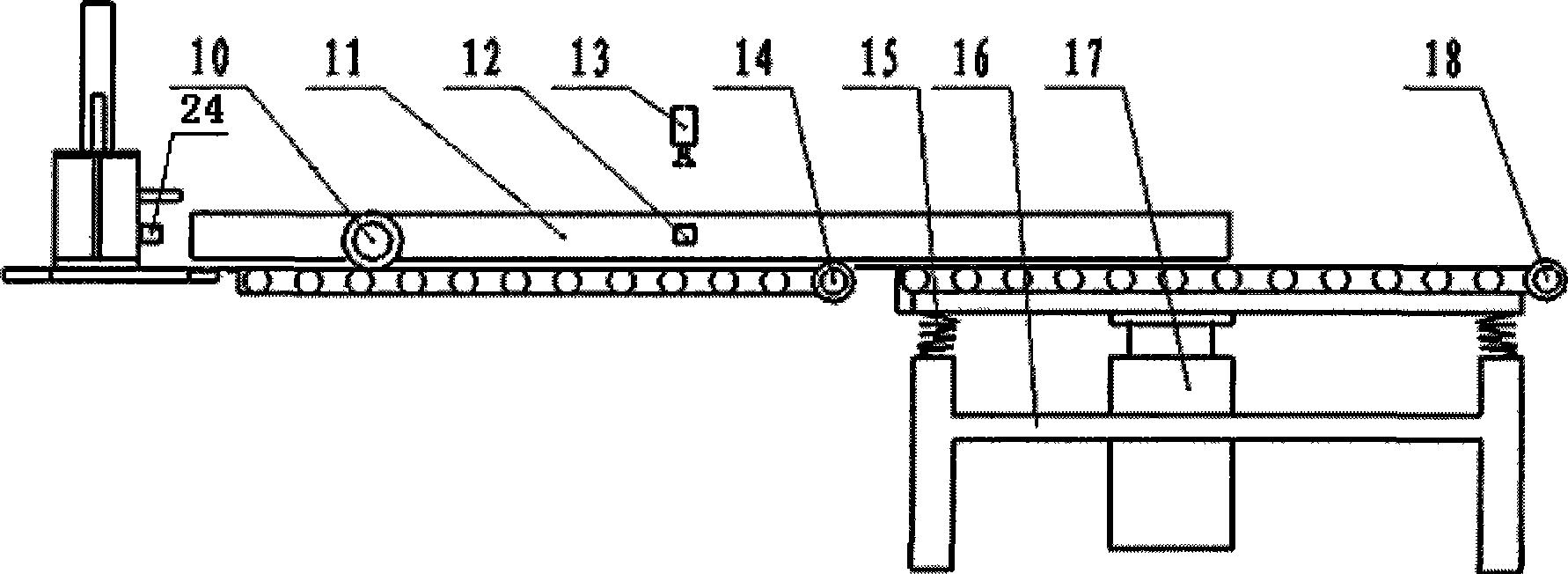

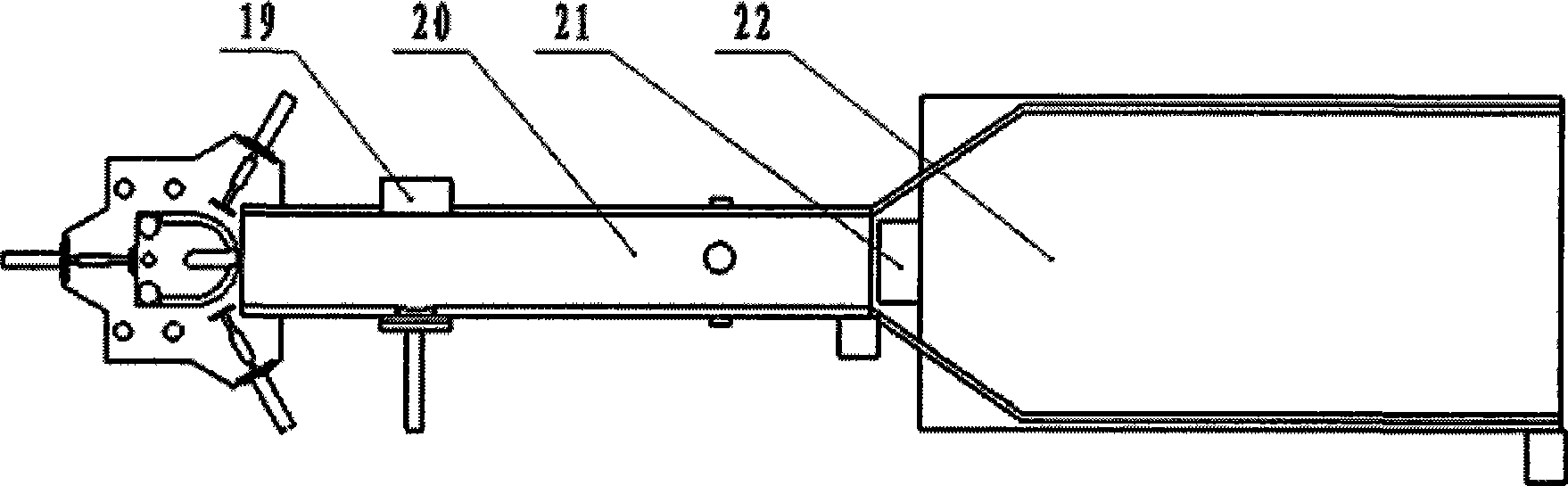

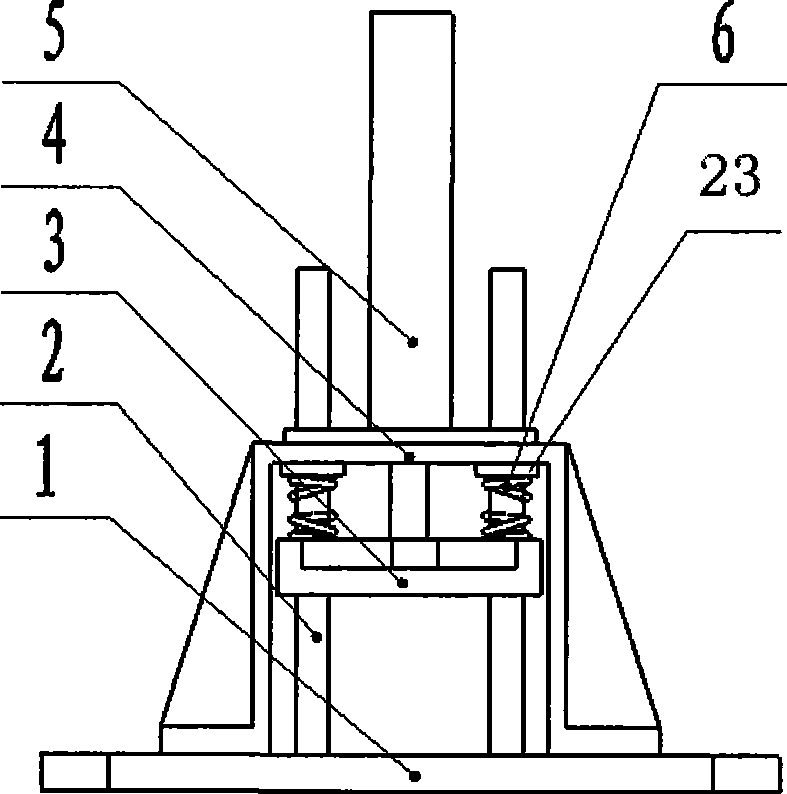

[0012] see figure 1 , 2. The present invention includes a vibrating conveying device, an apple conveying and apple direction detection and rejecting device, and a fruit inserting device. Belt 22 and the first drive motor 18, the vibration motor 17 is also fixedly connected on the first conveyor belt 22, the apple conveying and apple direction detection and rejecting device comprises the second conveyor belt 20 and the second drive motor 14, the second conveyor belt 20 passes through Connecting plate 21 is docked with the first conveyer belt 22, and the rotating speed of the first drive motor 18 is less than the second drive motor 14, and the apple that comes over from the first conveyer belt 22 can slide on the second conveyer belt by this connecting plate 21 smoothly, the second The upper end of conveyor belt 20 is also provided with photoelectric sensor 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com