Load-transfer machine for tyres

A loader and tire technology, applied to conveyor objects, lifting devices, lifting frames, etc., can solve the problems of relatively high workpiece positioning requirements, large floor space, and small transfer volume, etc., to ensure production tact and floor space The effect of small size and large reprint volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

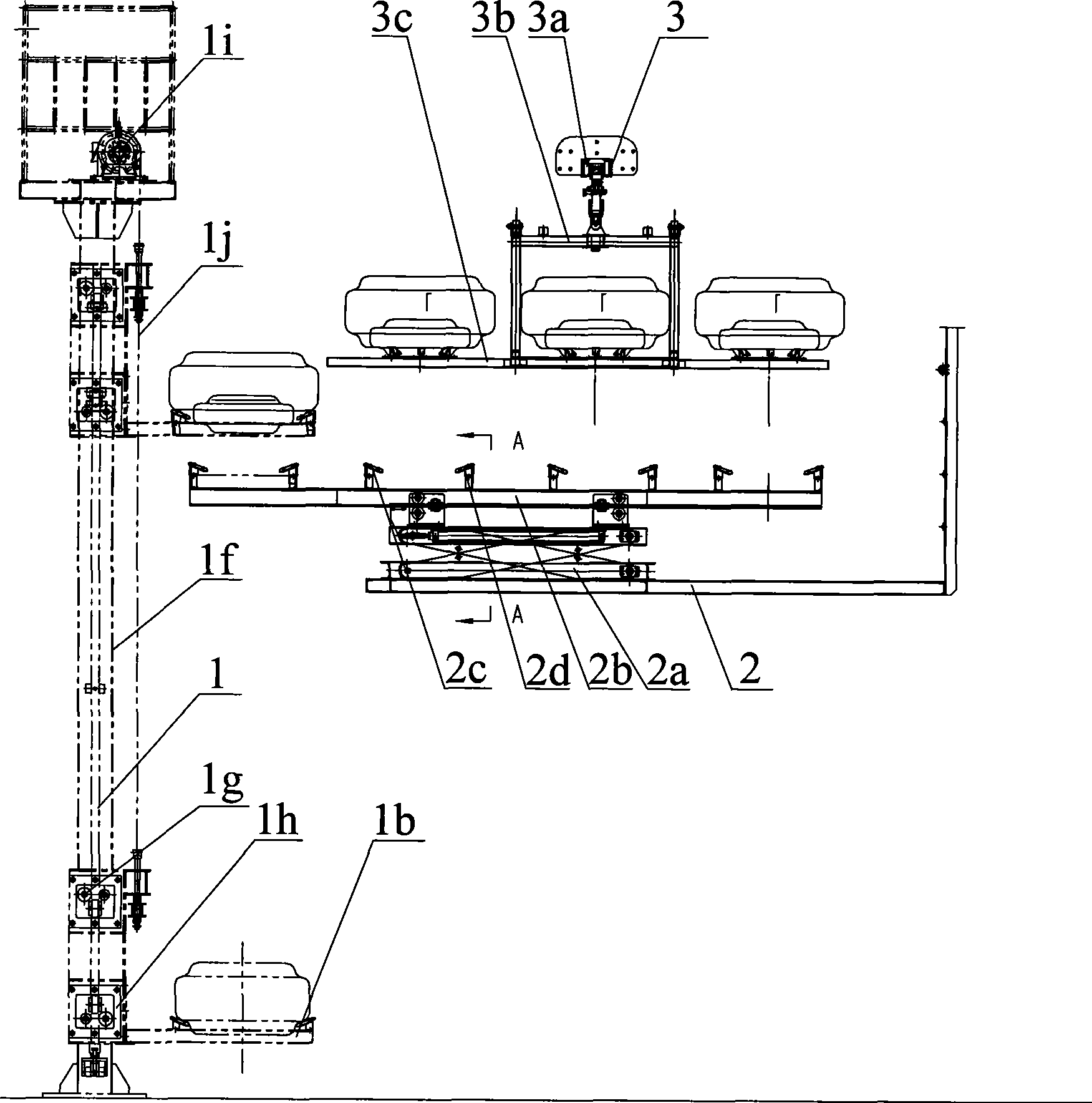

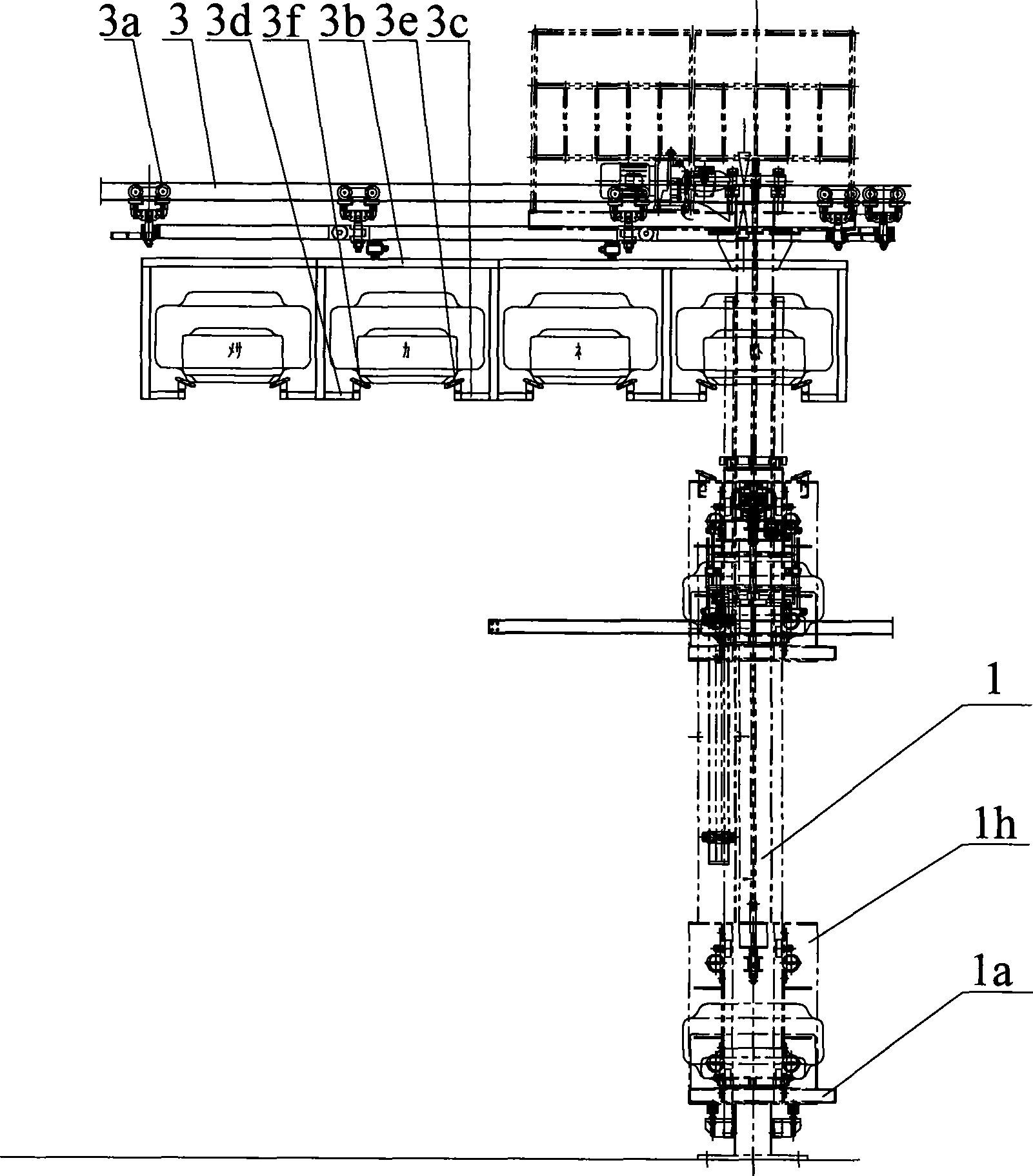

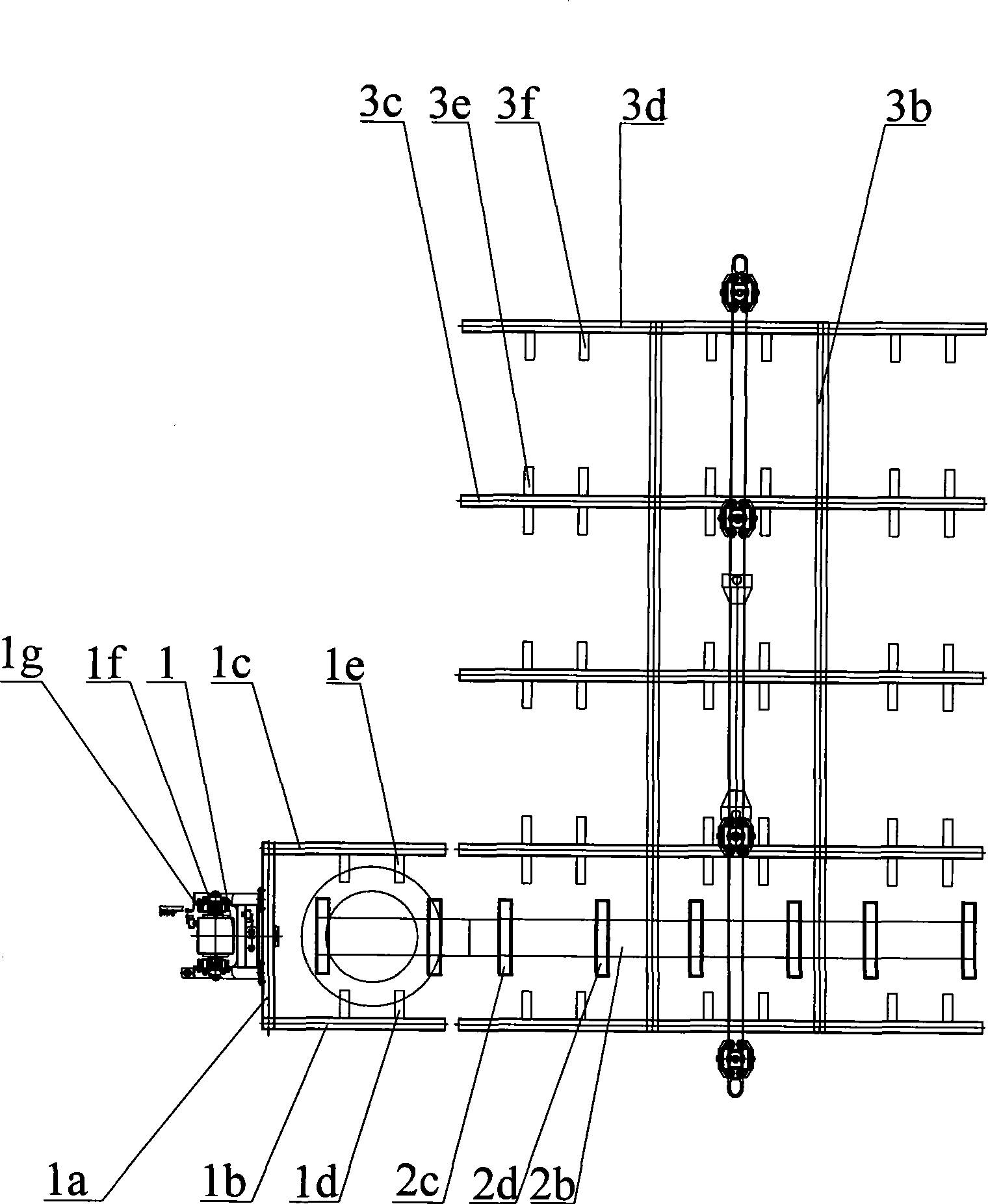

[0012] As shown in the figure: the tire transfer machine of the present invention is mainly composed of a column 1, a lifting carriage 1a, a first load bar 1b, a second load bar 1c, a first bracket 1d, a second bracket 1e, a lift rail 1f, a lift Traveling wheel 1g, sliding sleeve 1h, driving sprocket 1i, driving chain 1j, reloading base body 2, lifting platform device 2a, telescopic reloading rod 2b, first reloading bracket 2c, second reloading bracket 2d, conveying track 3, The traveling wheels 3a, the conveying frame body 3b, the third bearing rod 3c, the fourth bearing rod 3d, the third bracket 3e, and the fourth bracket 3f are composed of.

[0013] It includes the lifting carriage 1a and its lifting drive device arranged on the column 1, the first bearing rod 1b and the second bearing rod 1c protruding laterally are arranged at intervals on the inner and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com