Method for purification of sodium bromate by energy-saving method

A technology of sodium bromate and sulfate, which is applied in the direction of bromine oxy compounds, can solve the problems of poor color treatment effect, more steam consumption, and low purity, and achieve the effects of good product color, water saving, and steam saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

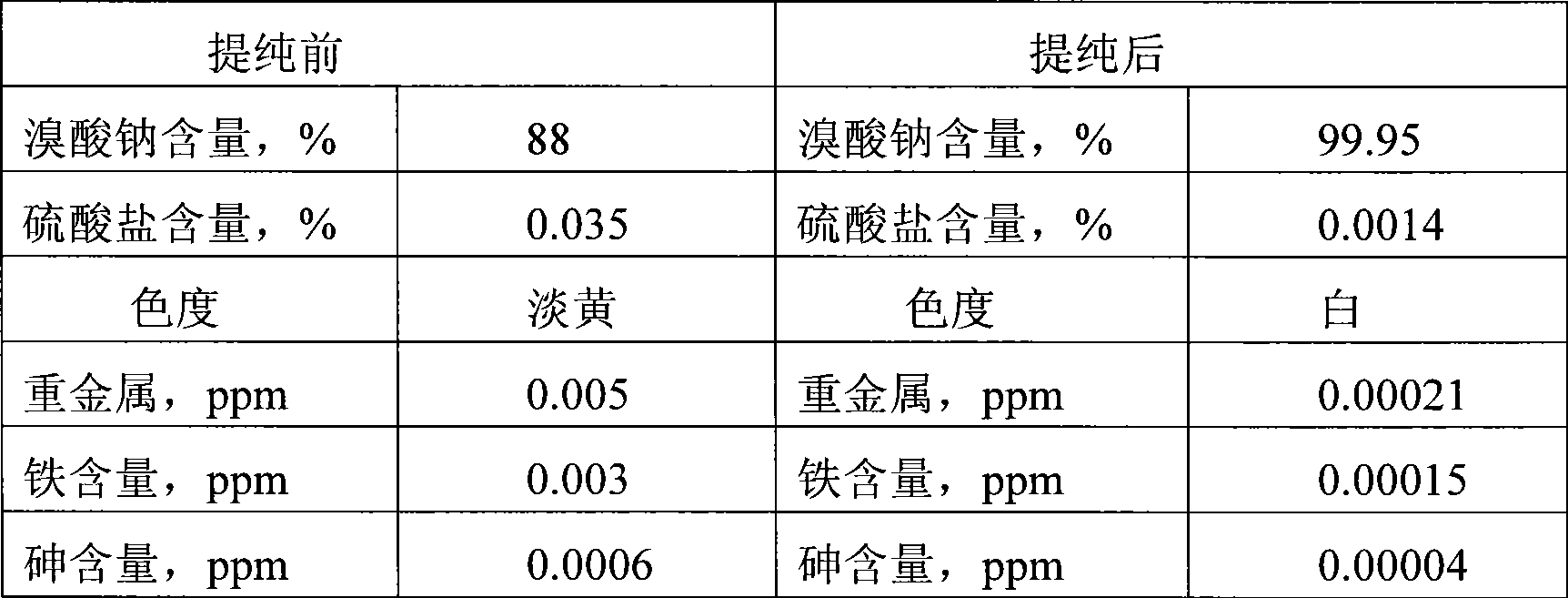

Embodiment 1

[0017] 1. Pour 1000L of deionized water into a 2000L glass-lined reactor with a stirrer (called No. 1 kettle), then add 75 kg of crude product sodium bromate to the reactor, stir and heat up to 90 degrees at the same time. The sodium bromate was completely dissolved.

[0018] 2. Add 4.5 kg of barium hydroxide, 1.2 kg of 80-mesh chitosan, and 4 kg of activated carbon into the reaction kettle, stir and dissolve for 50 minutes, so that the sulfate radical is precipitated as barium sulfate salt, the color is absorbed by activated carbon and chitosan, and the heavy metal is absorbed. Chitosan adsorption and chelation.

[0019] 3. Filter the feed liquid quickly through a filter with a 200-mesh filter cloth, and then pass through a sand filter for a second time and then transfer it to another 2000L glass-lined reaction kettle with a 30 rpm stirrer (No. 2 kettle) .

[0020] 4. Put circulating water into the jacket to cool, and start stirring at the same time, until the temperature o...

Embodiment 2

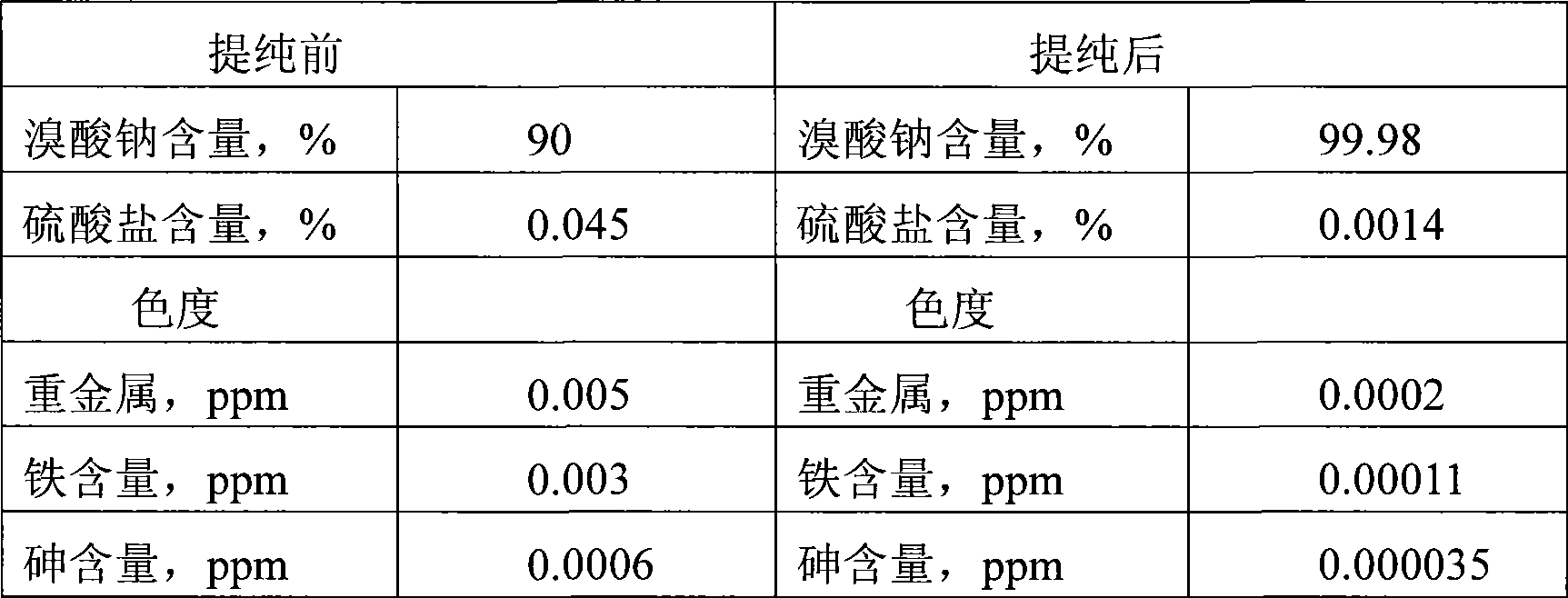

[0029] 1. Pour 1000L of deionized water into a 2000L glass-lined reactor with agitator (called No. 1 kettle), then add 75 kg of sodium bromate to be purified into the reactor, stir and heat up to 88 degree to completely dissolve the sodium bromate.

[0030] 2. Add 5.5 kg of barium hydroxide, 1.8 kg of 80-mesh chitosan, and 2.6 kg of activated carbon into the reaction kettle, stir and dissolve for 40 minutes, so that the sulfate radical is precipitated as barium sulfate salt, the color is absorbed by activated carbon and chitosan, and the heavy metal is absorbed. Chitosan adsorption and chelation.

[0031] 3. Filter the feed liquid quickly through a filter with a 150-mesh filter cloth, and then pass through a sand filter for a second time and then transfer it to another 2000L glass-lined reaction kettle with a 30 rpm stirrer (No. 2 kettle) .

[0032] 4. Put circulating water into the jacket to cool, and start stirring at the same time until the temperature of the feed liquid ...

Embodiment 3

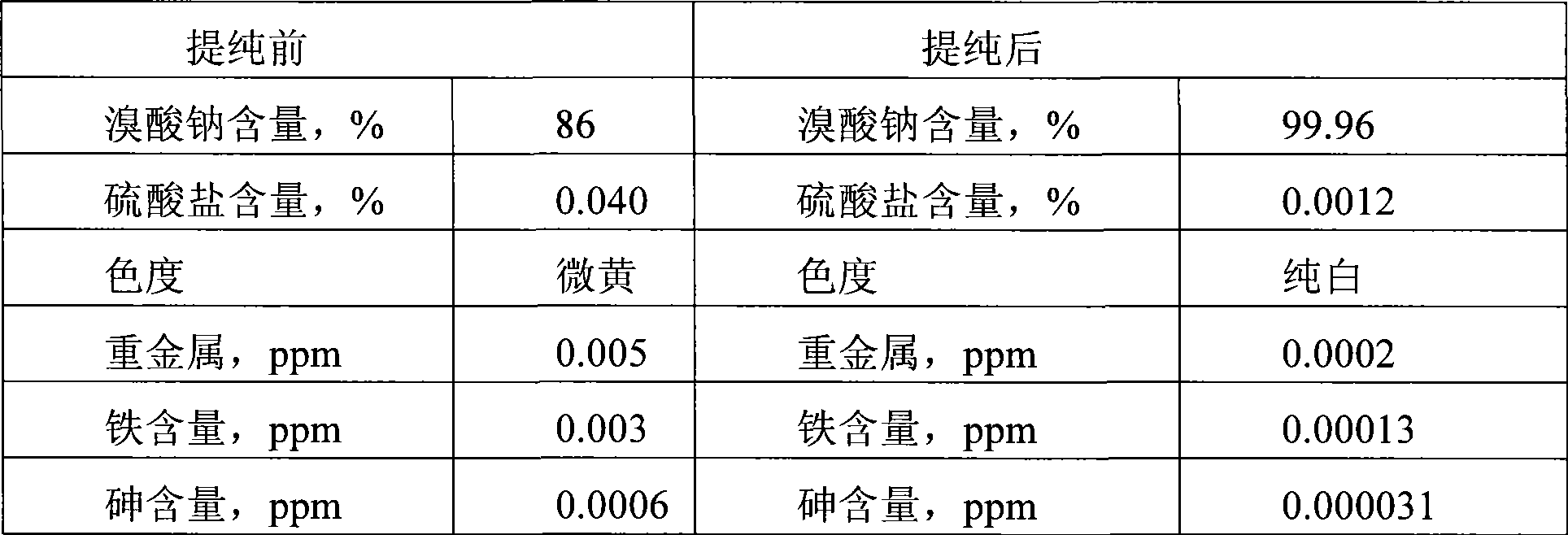

[0041] 1. Pour 1000L deionized water into a 2000L glass-lined reactor with a stirrer (called No. 1 kettle), then add 75 kg of sodium bromate to be purified into the reactor, stir and heat up to 85 degree to completely dissolve the sodium bromate.

[0042] 2. Add 4.0 kg of barium hydroxide, 1.5 kg of 80-mesh chitosan, and 3.0 kg of activated carbon into the reaction kettle, stir and dissolve for 45 minutes, so that the sulfate radical is precipitated as barium sulfate salt, the color is absorbed by activated carbon and chitosan, and the heavy metal is absorbed. Chitosan adsorption and chelation.

[0043] 3. Filter the feed liquid quickly through a filter with a 180-mesh filter cloth, and then pass through a sand filter for a second time and then transfer it to another 2000L glass-lined reaction kettle with a 35 rpm stirrer (No. 2 kettle) .

[0044] 4. Put the circulating water into the jacket to cool, and start stirring at the same time, until the temperature of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com