Wet zinc metallurgical ultrasound purification method, device and use

A purification device and wet process technology, applied in the field of hydrometallurgical zinc metallurgy purification, can solve the problems of unfavorable ultrasonic strengthening effect, unsatisfactory industrialization effect, and unstable ultrasonic irradiation effect, and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

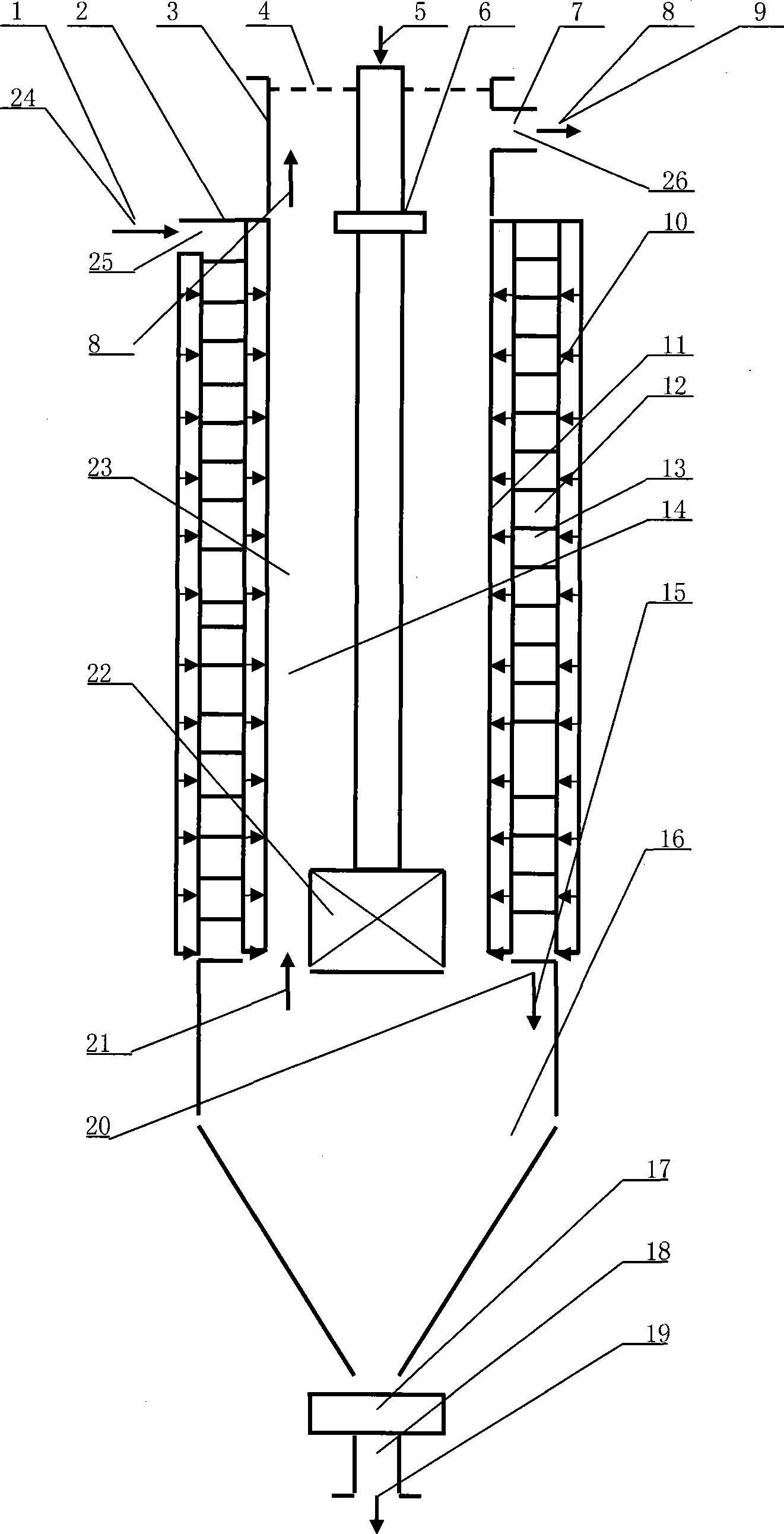

[0035] pass figure 1 It can be seen that the present invention is an ultrasonic purification method for wet zinc metallurgy. In the ultrasonic purification device for wet zinc metallurgy, the ultrasonic sound field generated by ultrasonic waves is used to perform irreversible ultrasonic irradiation on the wet zinc metallurgy solution to be purified, so that the liquid after the purification reaction The concentration of ionic impurity tends to decrease irreversibly, so as to achieve the purpose of impurity removal. The ultrasonic sound field at least includes a frequency of 15-28kHz and a sound intensity of 0.5-5w / cm 2 ultrasonic sound field. The hydrometallurgical solution to be purified is the solution after leaching of zinc ore powder containing copper, cadmium, cobalt, and nickel ionic impurities (commonly known as the supernatant), and the concentration range of the ionic impurities includes at least: copper ≤2000mg / L and (or) cadmium ≤2000mg / L and (or) cobalt ≤200mg / L ...

Embodiment 2

[0040] figure 1 For another embodiment of the present invention, from figure 1 It can be seen that the present invention is an ultrasonic purification device for realizing the ultrasonic purification method of wet zinc metallurgy.

[0041] The ultrasonic purification device for wet zinc metallurgy includes at least one ultrasonic purification reaction chamber 3 filled with the solution 1 to be purified. The ultrasonic purification reaction chamber can be open at the top and vertically cylindrical or positive at the top. The combination cavity is polygonal cylindrical and the lower part is converging downward, and is provided with an inlet 2 for the solution to be purified, an outlet 7 for the liquid after the ultrasonic purification reaction, and a bottom outflow port 18 for the liquid after the ultrasonic purification reaction. In the middle of the ultrasonic purification reaction chamber, there is an ultrasonic sound field with a frequency of 15kHz and a sound intensity of ...

Embodiment 3

[0046] Conventional supernatant ultrasonic purification process for producing total slag of copper, cadmium, cobalt and nickel: two-stage ultrasonic purification process.

[0047] The first-stage ultrasonic purification process: remove copper, cadmium, cobalt and nickel, and produce total slag of copper, cadmium, cobalt and nickel.

[0048] The purification temperature is 70-85°C, and the ultrasonic purification time is 5 minutes. Among them, the purification time of irreversible ultrasonic irradiation area A is 2 minutes, and the purification time of irreversible ultrasonic irradiation area B is 3 minutes.

[0049] The solution to be purified at 70-85°C enters the mixing tank first, and the amount of zinc powder corresponding to the content of ionic impurities copper + cadmium in the solution to be purified is 1:1-1.5, the amount of zinc powder corresponding to the content of cobalt 1:20-100, and the content of nickel The amount of zinc powder corresponding to 1:20-50 is add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com