Soft conductive structure in cathode roller of foil manufacturing machine and calculating method of conductive belt section area

A technology of conductive structure and conductive strip, applied in the field of copper foil manufacturing, can solve the problems of unstable conductive performance, low production efficiency, difficult processing, etc., and achieve the effects of high production efficiency, convenient processing, and enhanced conductive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

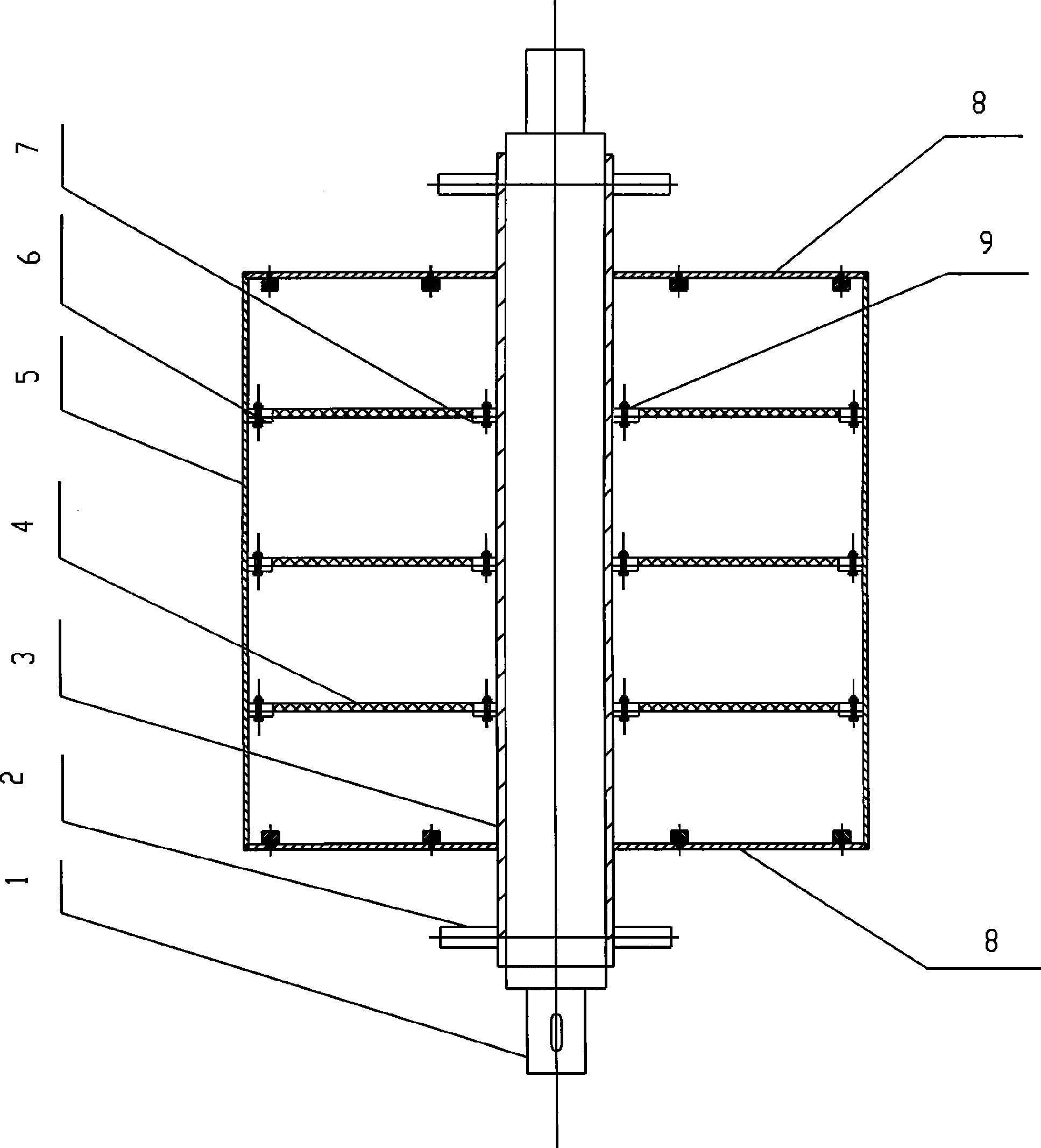

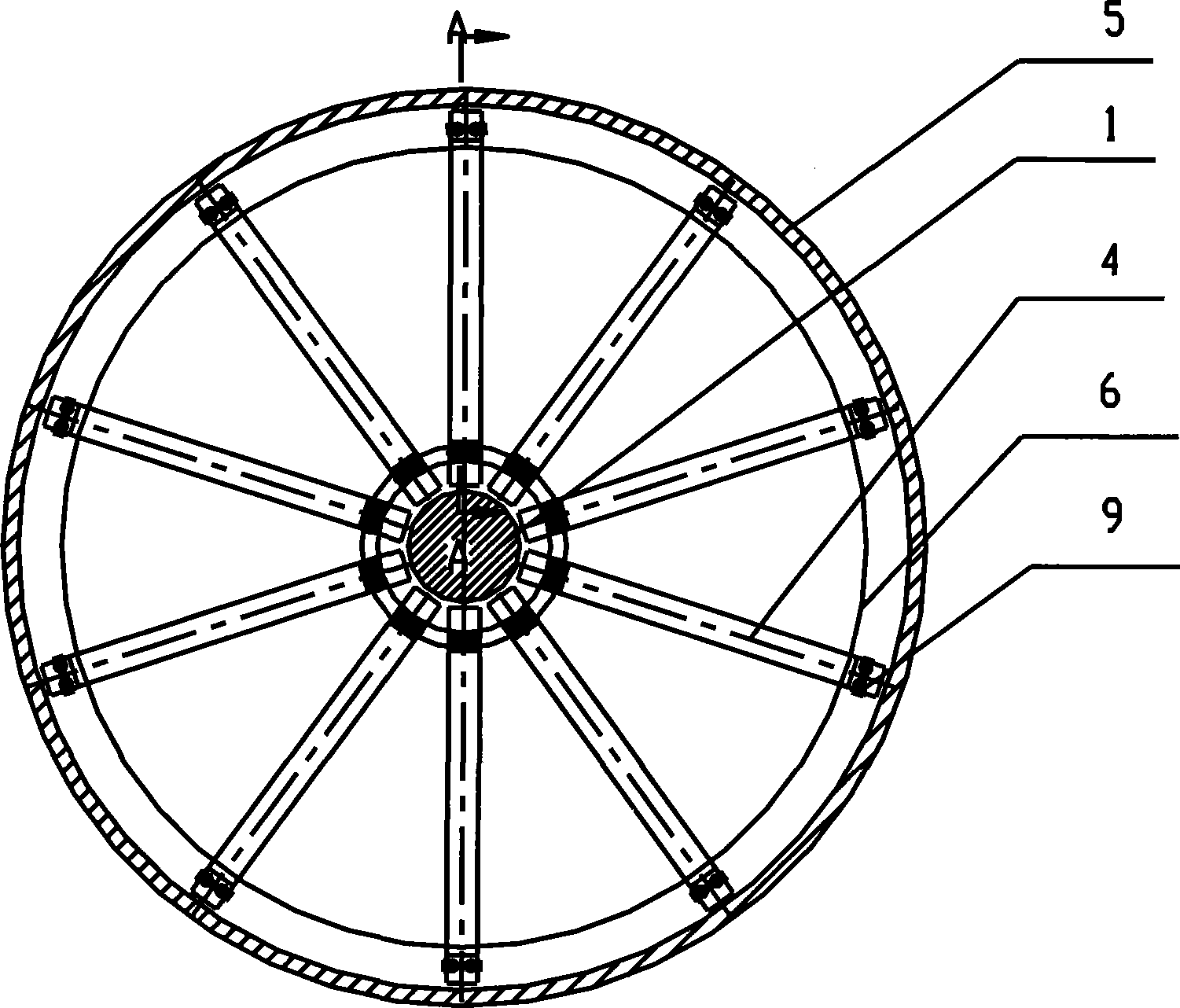

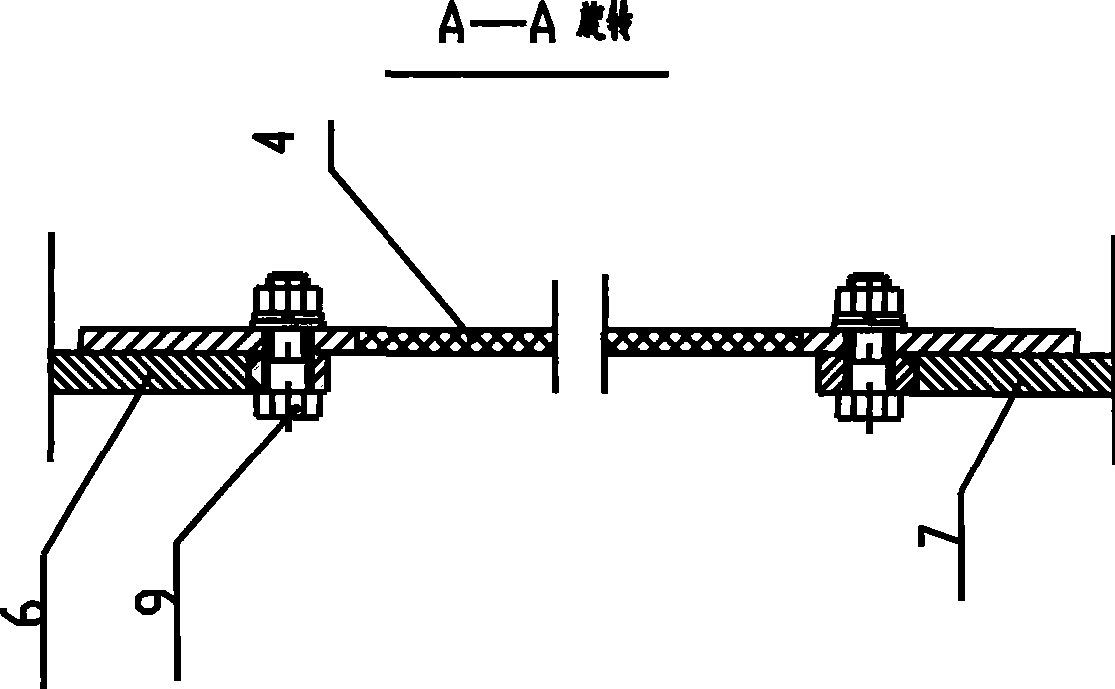

[0028] This embodiment is used to produce 12um-25um electrolytic copper foil internal soft conductive structure of the single-layer titanium cathode roller, the diameter of the cathode roller is 1.5m, including multiple sets of conductive strips 4, conductive shaft sleeves 3, conductive copper rings 2, joint sleeves 10, main shaft 1, titanium cylinder 5 and end plates 8. Wherein the main shaft 1, the conductive copper ring 2, the conductive shaft sleeve 3, the titanium ring 6 and the end plate 8 all adopt the prior art; the titanium ring 6 is processed into a circular flange plate after using a titanium plate, and is welded on the inner wall of the titanium cylinder. Fixedly connect the conductive strip joint with the titanium ring. When connecting, because the braided belt is used to realize the soft connection method, the conductive belt is connected with the conductive sleeve and the roller surface, so that the current is evenly transmitted from the cathode roller sleeve t...

Embodiment 2

[0040] This embodiment is used to produce 12um-35um electrolytic copper foil inner soft conductive structure of the single-layer titanium cathode roller, the diameter of the cathode roller is 2m, including multiple sets of conductive strips 4, conductive shaft sleeves 3, conductive copper rings 2, joint sleeves 10, main shaft 1, titanium cylinder 5 and end plates 8. Wherein the main shaft 1, the conductive copper ring 2, the conductive shaft sleeve 3, the titanium ring 6 and the end plate 8 all adopt the prior art; the titanium ring 6 is processed into a circular flange plate after using a titanium plate, and is welded on the inner wall of the titanium cylinder. Fixedly connect the conductive strip joint with the titanium ring. When connecting, because the braided belt is used to realize the soft connection method, the conductive belt is connected with the conductive sleeve and the roller surface, so that the current is evenly transmitted from the cathode roller sleeve to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com