Plastic pump for high pressure cleaning machine

A technology for high-pressure cleaners and plastic pumps, which is applied in the directions of pumps, mechanical equipment, machines/engines, etc., can solve the problems of complex structure, poor corrosion resistance, poor wear resistance, affecting the appearance of the cleaning machine, etc. The effect of light weight, excellent wear resistance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

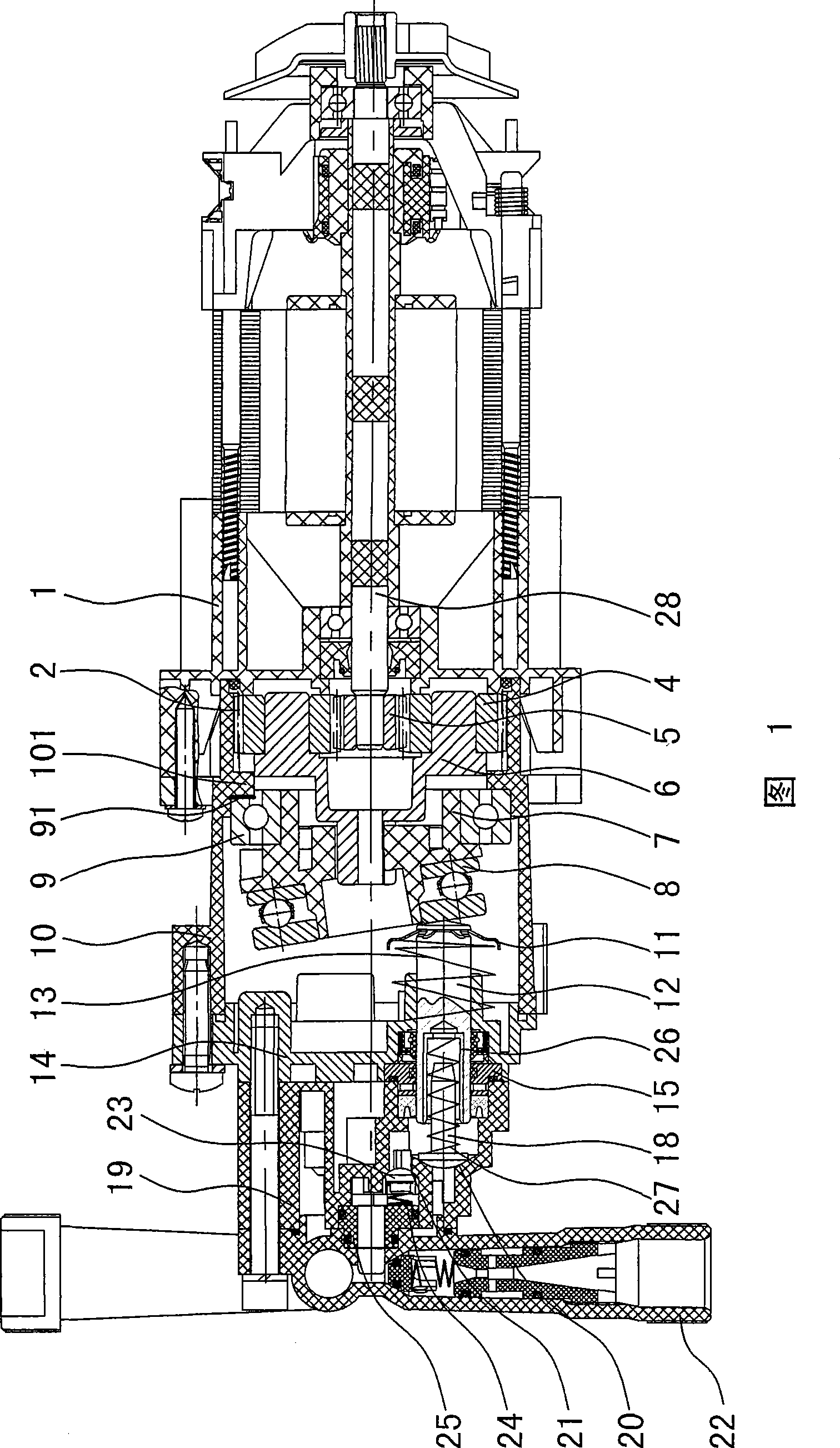

[0008] The invention discloses a plastic pump for a high-pressure cleaning machine, as shown in Figure 1, comprising a series excitation motor 1 and an axial plunger pump, a speed reduction mechanism is provided between the motor 1 and the axial plunger pump, and the axial plunger pump The plug pump includes a pump base 10, a pump body 14, a pump head 19 and a pump cover 22. The pump base 10 is connected to the motor 1 shell, and the force is transmitted to the bearing housing 7 in the pump base 10 through a reduction mechanism. The bearing housing 7 is equipped with a thrust ball. The bearing 8 and the thrust ball bearing 8 are in contact with the circlip 11 installed in the outer groove of the plunger 12, the circlip 11 is equipped with a spring 13, the other end of the spring 13 is installed on the boss of the pump body 14, and the pump body 14 is connected to Pump base 10 and pump head 19, pump body 14 is equipped with middle sleeve 15, middle sleeve 15 is equipped with plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com