Conductive paste and solar cell

A solar cell and electrical conductivity technology, applied in the field of solar cells and light-receiving surface electrodes, can solve the problem of no glass frit display, etc., and achieve the effects of improving bonding strength, superior environmental resistance, and superior reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be clarified by describing specific embodiments of the present invention with reference to the drawings.

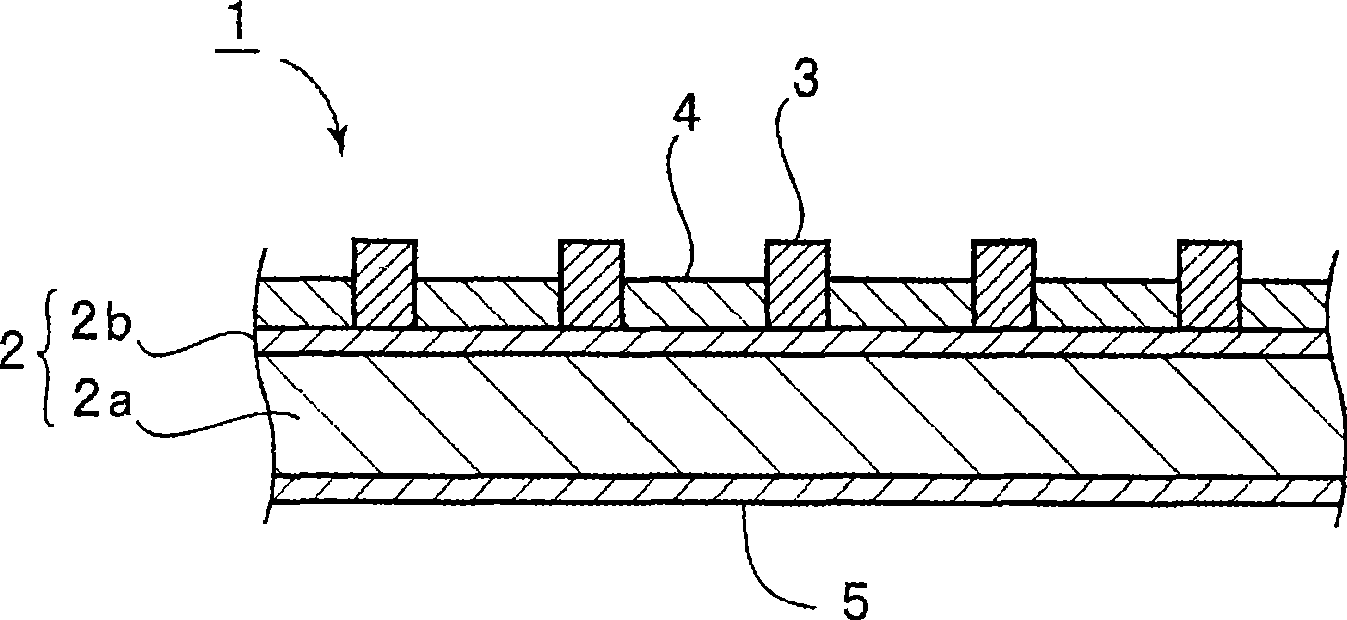

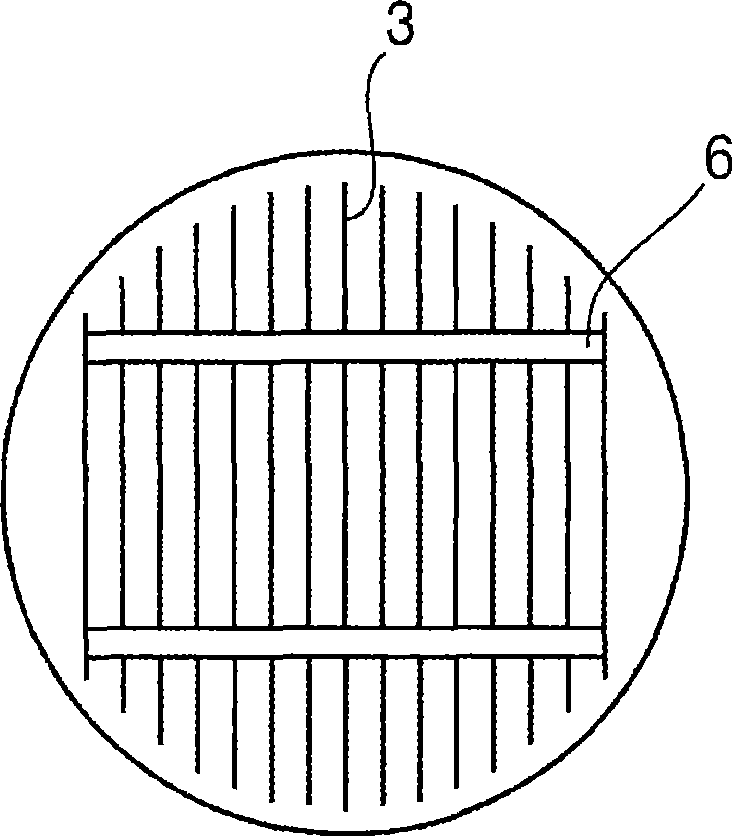

[0025] figure 1 is a partially broken front cross-sectional view showing a solar cell according to an embodiment of the present invention, figure 2 is a partially enlarged plan view schematically showing the electrode structure formed on the upper surface thereof.

[0026] The solar cell 1 has a semiconductor substrate 2 . The semiconductor substrate 2 has a structure in which an n-type Si-based semiconductor layer 2b is formed on an upper surface of a p-type Si-based semiconductor layer 2a. Such a semiconductor substrate 2 is obtained by diffusing impurities on one side of a p-type Si-based semiconductor substrate to form an n-type semiconductor layer 2b. However, the structure and manufacturing method of the semiconductor substrate 2 are not particularly limited as long as the n-type Si-based semiconductor layer 2b is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com