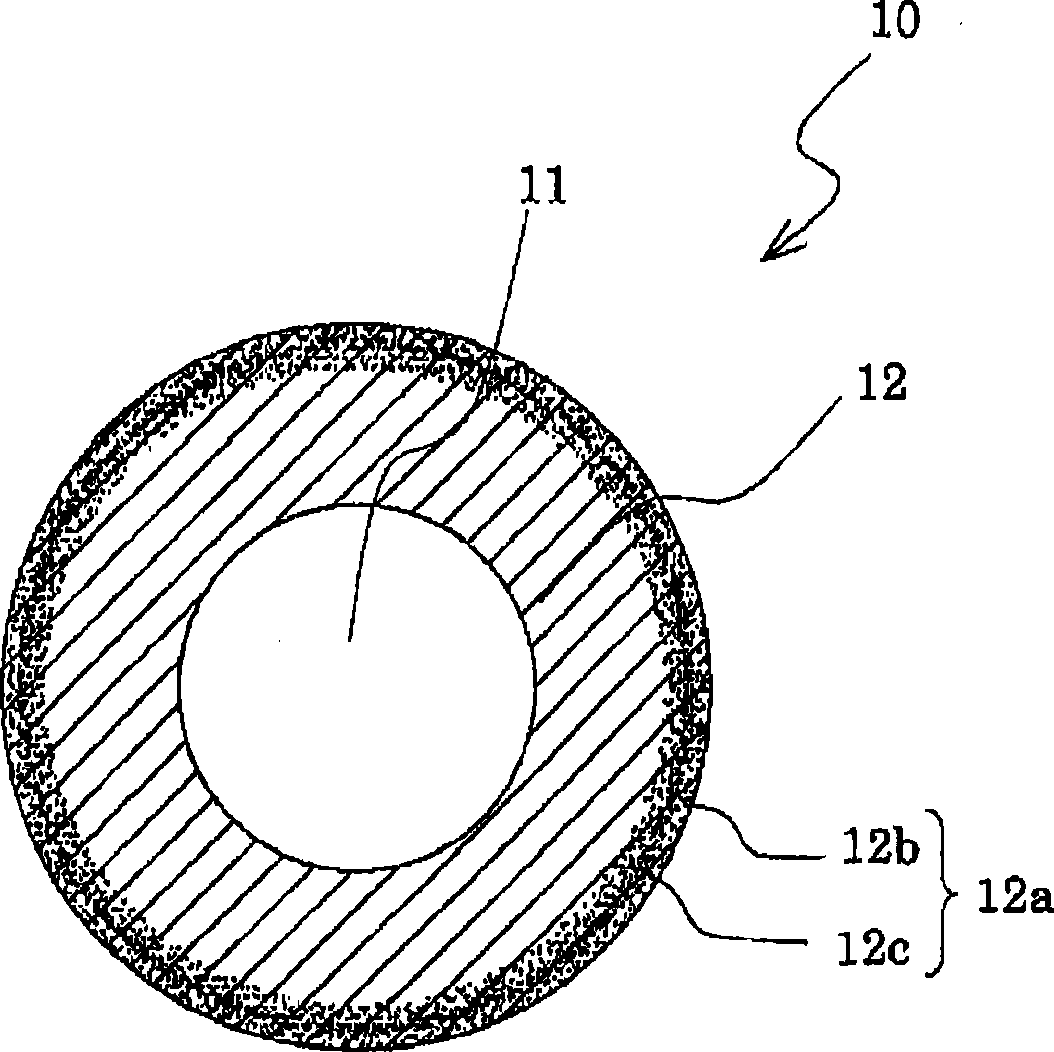

Conductive rubber member

A conductive and rubber technology, which is applied in the direction of electrography, electric recording process using charge pattern, equipment of electric recording process applying charge pattern, etc. requirements, etc., to achieve the effect of small resistance value changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

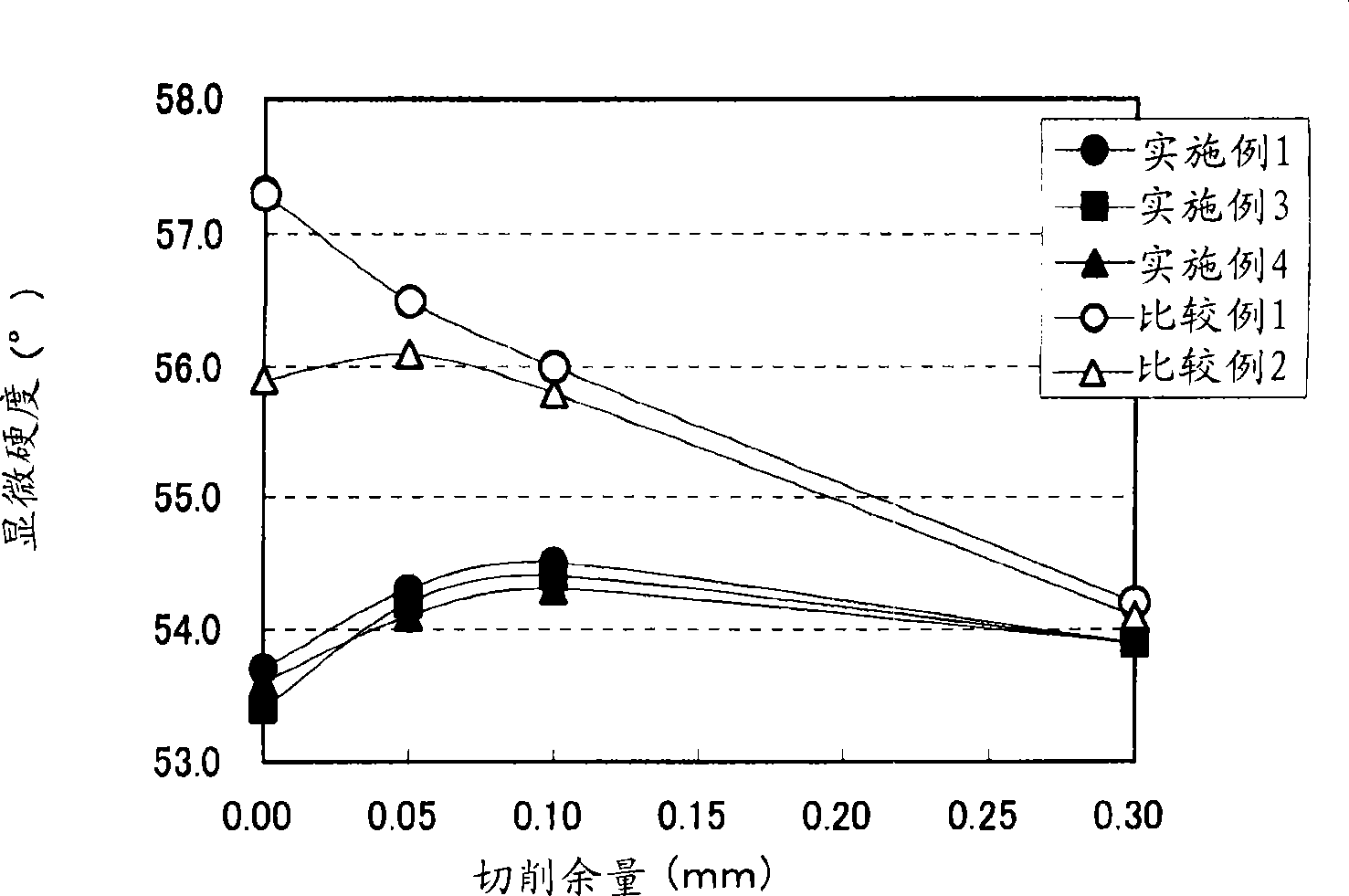

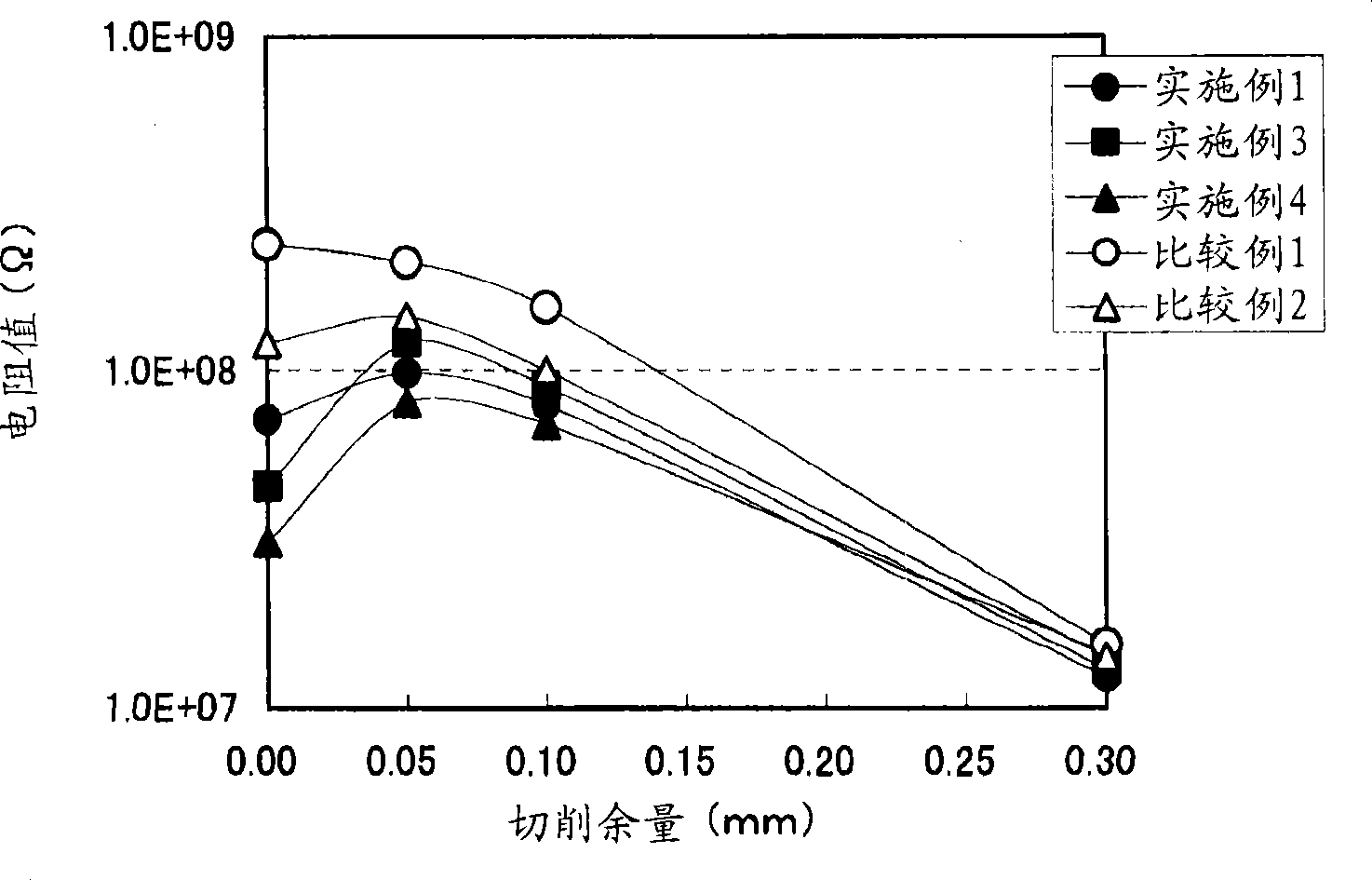

Examples

Embodiment 1

[0062]

[0063] To 100 parts by weight of trifunctional polyether-based polyol MN-3050 (manufactured by Mitsui Takeda Homikar), 3 parts by weight of Hitchen Black EC (manufactured by Hitchen Black Inta-Nase Yonal Co.) and Asahi #60 (made by Asahi Ka-bon) were added. ) in 5 parts by weight to disperse to a particle size below 20 μm, and after temperature adjustment to 80° C., defoaming and dehydration operations were carried out for 6 hours under reduced pressure to obtain liquid A. On the other hand, 10 parts by weight of Coronet C-HX (manufactured by Nippon Polyuretan Co., Ltd.) was added and mixed to 22 parts by weight of Premium Polyma-Ajiplen L100 (manufactured by Uniroyal Co., Ltd.), and the temperature was adjusted to 80° C. to obtain liquid B. Mix liquid A and liquid B and inject it into an iron pipe mold with a diameter of 23mm that is preheated to 120°C with a shaft (φ8mm, 1:270mm) in the center, and heat at 120°C for 120 minutes to obtain A roller having a conducti...

Embodiment 2

[0069]

[0070] 0.5 parts by weight of tetraethylammonium perchlorate (manufactured by Kanto Chemical Co., Ltd.) as a conductive agent was kneaded with a roll mixer with respect to 100 parts by weight of epichlorohydrin rubber (Epichroma-CG-102; manufactured by Daiso Co., Ltd.) 3 parts by weight of bis(2-ethylhexyl) phthalate (DOP) as a plasticizer, 5 parts by weight of zinc oxide (ZnO), 2 parts by weight of 2-mercaptoimidazoline (Axel-22) as a vulcanizing agent , was press-molded on the surface of a metal shaft with a diameter of 6 mm to obtain a roller having an epichlorohydrin rubber layer formed on the shaft surface. The surface of this roll was ground and processed, and the roll (before processing) whose outer diameter was adjusted to 12 mm was obtained.

[0071]

[0072] 20 parts by weight of isocyanate compound (HDI) was added and mixed and dissolved in 100 parts by weight of methyl isobutyl ketone to prepare a surface treatment liquid.

[0073]

[0074] After im...

Embodiment 3

[0076] Except for making the oven temperature 150 degreeC in the surface treatment of a roller, the same operation as Example 1 was performed, and the electroconductive roller of Example 3 was produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com