Heavy load precision damper and vibration reduction system formed thereby

A technology of vibration reduction system and shock absorber, which is applied in the direction of gas shock absorber, spring/shock absorber, vibration suppression adjustment, etc., which can solve the problem of limited pressure fluctuation adjustment ability, non-adjustable air spring damping, and difficult air spring stiffness. and other problems, to achieve the effect of vibration attenuation rate, precise positioning and high vibration attenuation rate

Inactive Publication Date: 2010-12-01

HUAZHONG UNIV OF SCI & TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the damping of the air spring is not adjustable, it relies entirely on the Lorentz motor to generate force to suppress the amplitude of low-frequency vibration; in addition, only relying on the air supply valve to actively adjust the air spring pressure, the ability to adjust pressure fluctuations is limited, and it is difficult to achieve air spring stiffness close to zero , so limited isolation from external vibration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

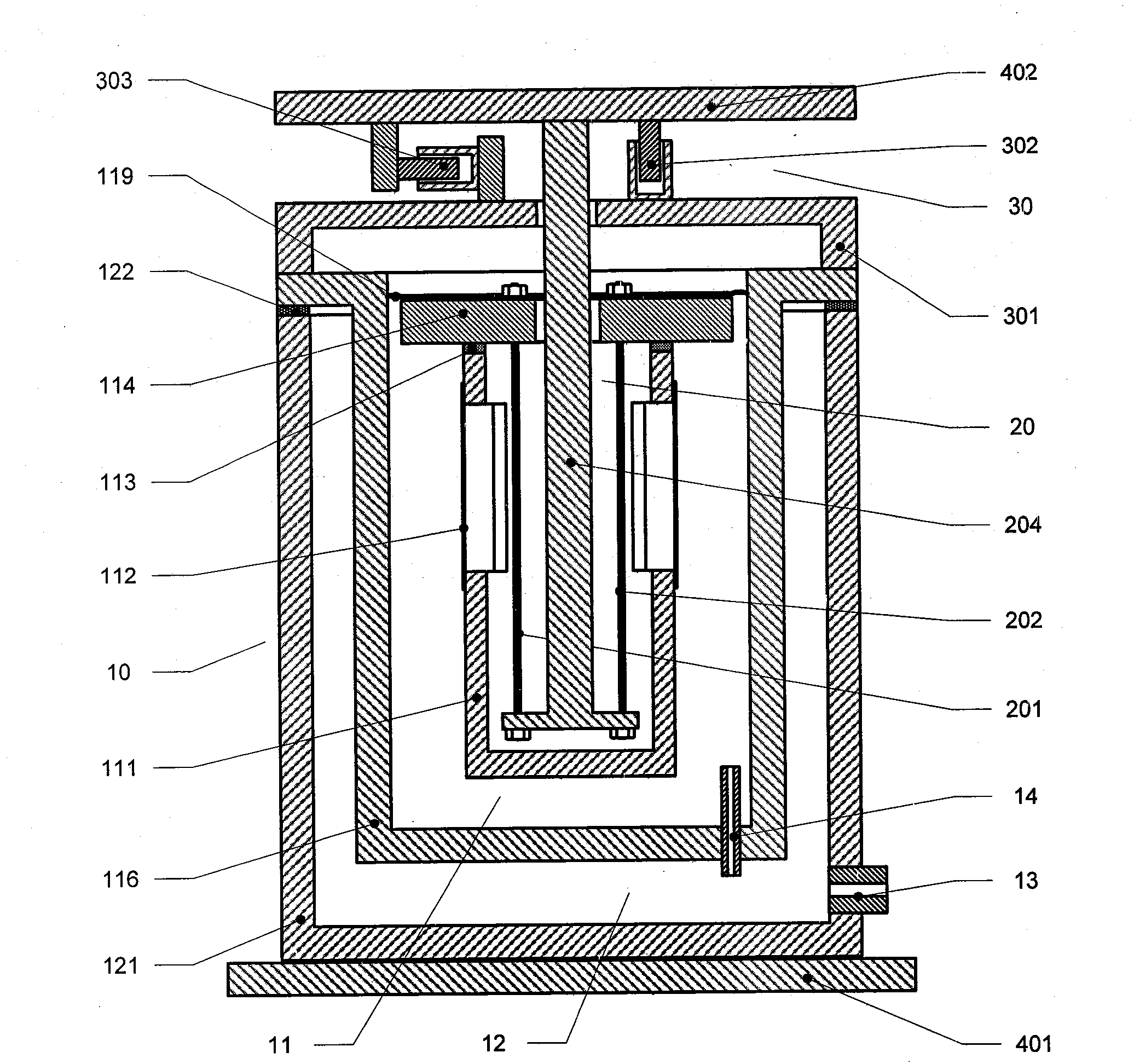

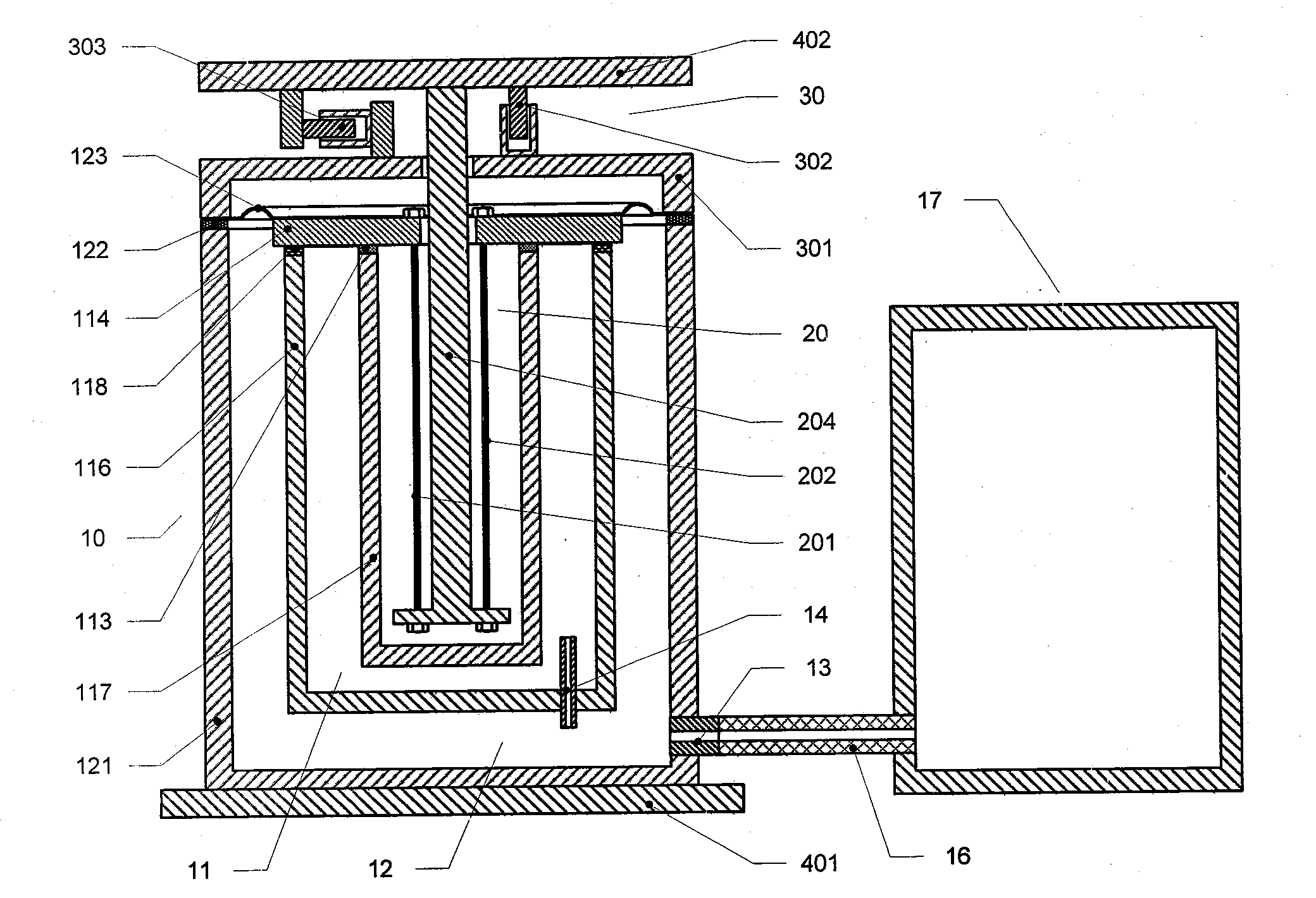

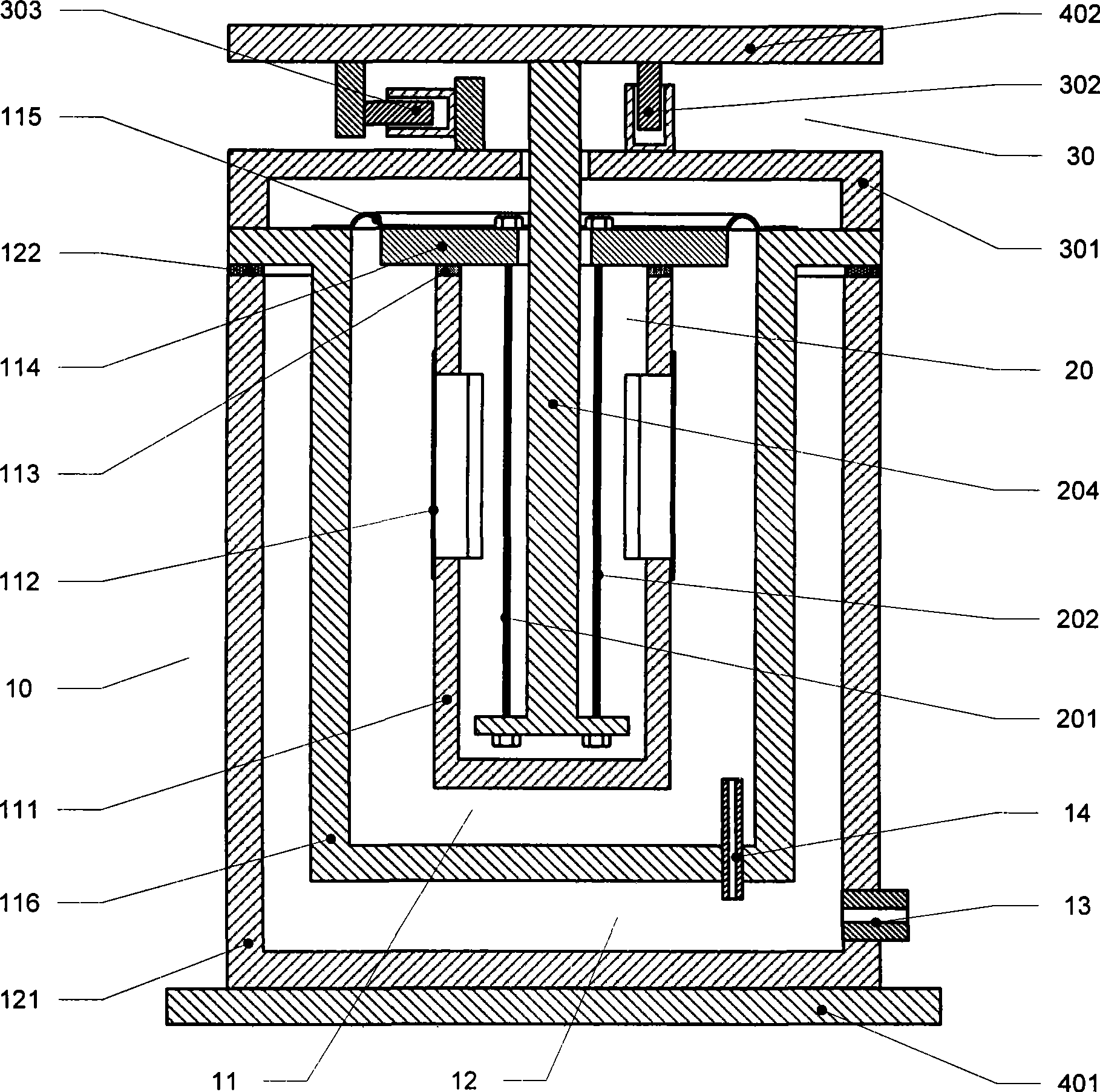

The invention pertains to the technical field of precision damping, and is a heavy-load precision damper and a damping system comprising thereof. The damper comprises a low-rigidity air spring with variable damp, an inverted-pendulum structure with low horizontal rigidity and a group of three-degree-of-freedom active damping actuators. The structure of the air spring is external-internal annularity double air chambers communicated with a throttling hole; the inverted-pendulum structure comprises a main supporting rod and at least two flexible swing rods and is located in an annular air chamber; and the active damping actuator comprises three linear motors arranged in an orthogonal manner. The heavy-load precision damper vertically generates large bearing force by the air spring, respectively separates vertical and horizontal vibration transmission by the air spring and the inverted-pendulum structure, and actively controls the damp vibration by acting force of the vertical and horizontal linear motors. The damping system comprises at least three heavy-load precision dampers arranged in the shape of a polygon, and realizes six-degree-of-freedom precision damping of a vibration-isolation device by the mutual action of every heavy-load precision dampers.

Description

A heavy-duty precision shock absorber and the shock absorbing system it constitutes technical field The invention belongs to the technical field of precision vibration damping, and specifically relates to a heavy-duty precision vibration damper and a vibration damping system composed of it. device. Background technique Precision vibration damping is widely used in extremely large-scale IC manufacturing, precision measurement, aerospace and other fields, mainly to isolate external vibrations. Among them, since the positioning accuracy of the lithography machine is required to be as high as several nanometers, the performance requirements for precision vibration reduction are currently the highest among all the above-mentioned equipment. The performance of precision vibration damping directly affects the motion performance of IC devices. The precise vibration damping device of the existing photolithography machine adopts the air spring of a single air chamber in series wi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16F9/02F16F15/023

Inventor 陈学东宋宝姜伟蒲华燕罗欣李小平曾理湛

Owner HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com