Nonreciprocal circuit element

A technology of circuit components and resistors, which is applied in the field of non-reciprocal circuit components, can solve the problems of inappropriate miniaturization and thinning, and achieve the effects of easy and attenuation, adjustable attenuation, and reliable out-of-band attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

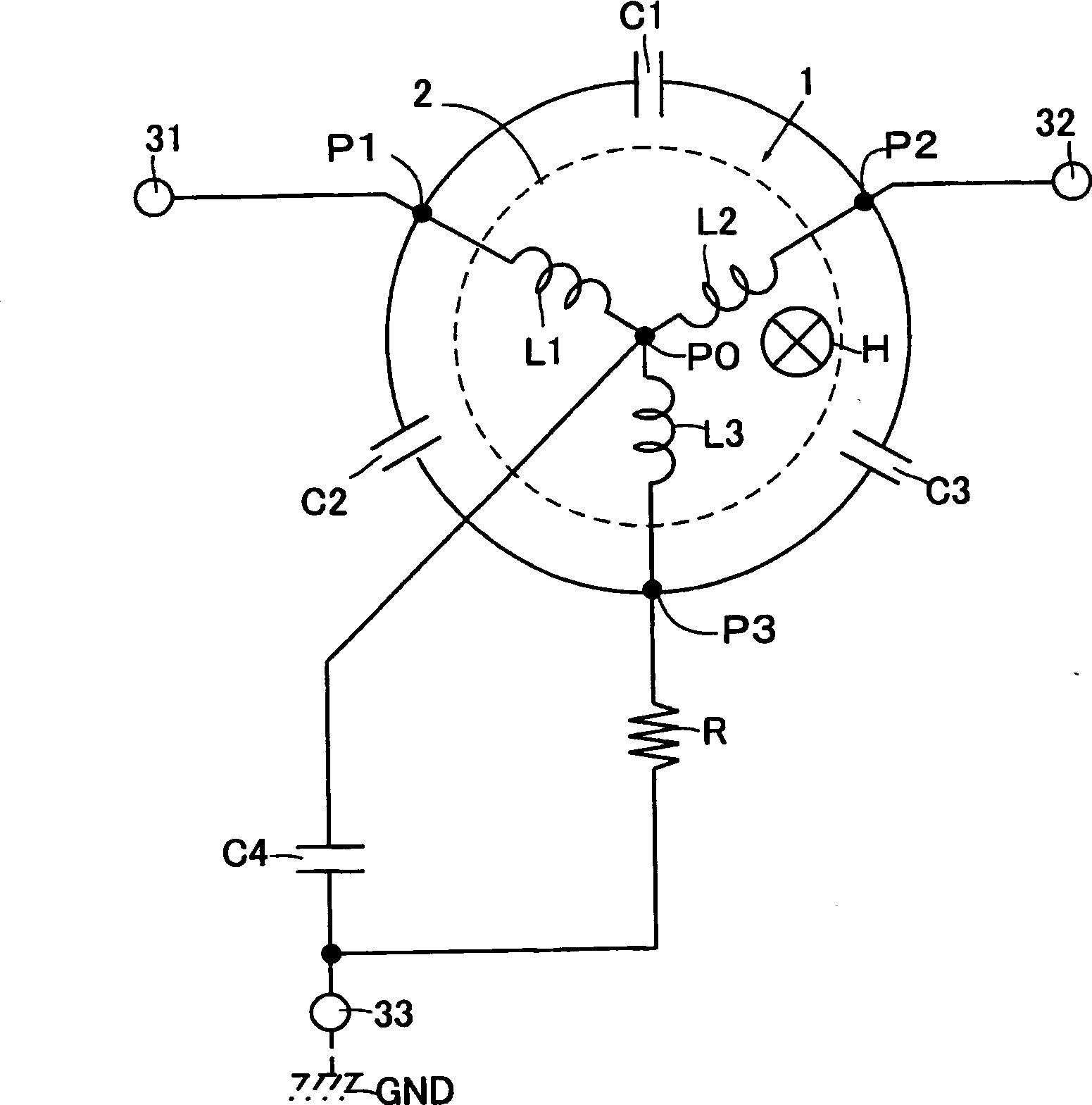

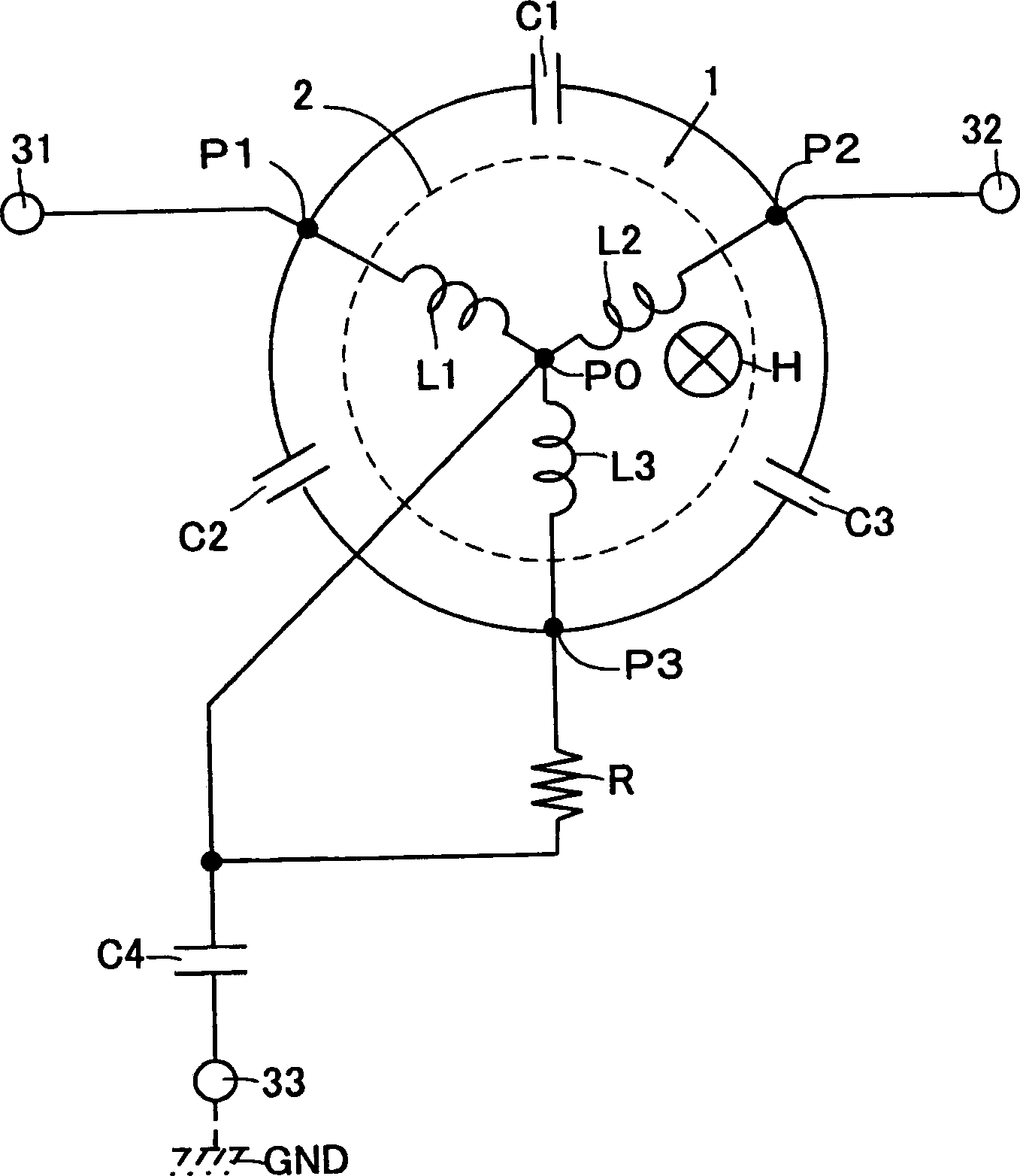

[0064] figure 1 It is a circuit diagram of the nonreciprocal circuit element involved in the present invention. The illustrated non-reciprocal circuit element includes a magnetic rotor 1 , first to fourth capacitors C1 to C4 and a terminal resistor R.

[0065] The magnetic rotor 1 includes a ferrite 2 and first to third center conductors L1 to L3. The ferrite 2 can be formed in any shape such as a disc shape, a square plate shape, or the like.

[0066] The first to third central conductors L1-L3 are connected to the ferrite 2 through the common node P0 with one end at the common potential. The first to third central conductors L1-L3 are made of metal materials such as Cu with good electrical conductivity and high-frequency characteristics. In addition to Cu plates, conductive paste with Cu or Ag as the main component can also be used for coating and sintering. and other well-known structures in the past. These first to third central conductors L1 to L3 are insulated from e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com