Processing method for basement water-proof concrete construction joint

A waterproof concrete and treatment method technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of groundwater infiltration, short leakage path of horizontal construction joints, and affect the quality of concrete surface perception, etc., to achieve enhanced anti-seepage Ability, perfect construction quality, and good perception of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

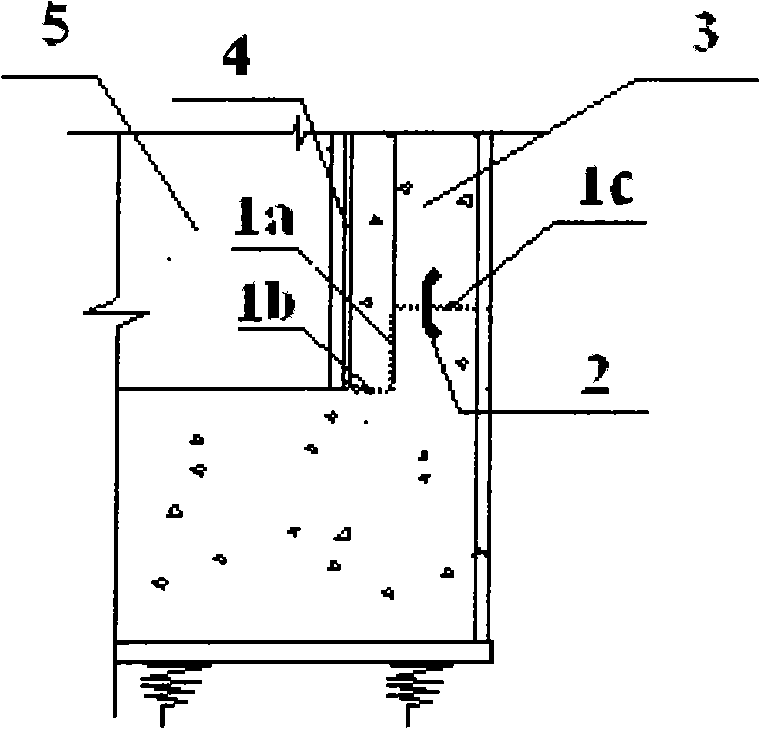

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Taking the cold-rolled sheet engineering rolling mill foundation construction as an example, the construction method of the present invention comprises the following steps:

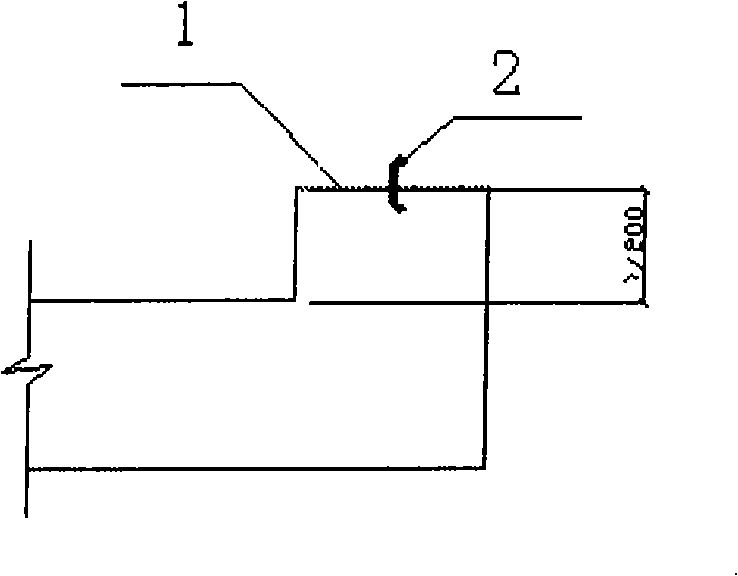

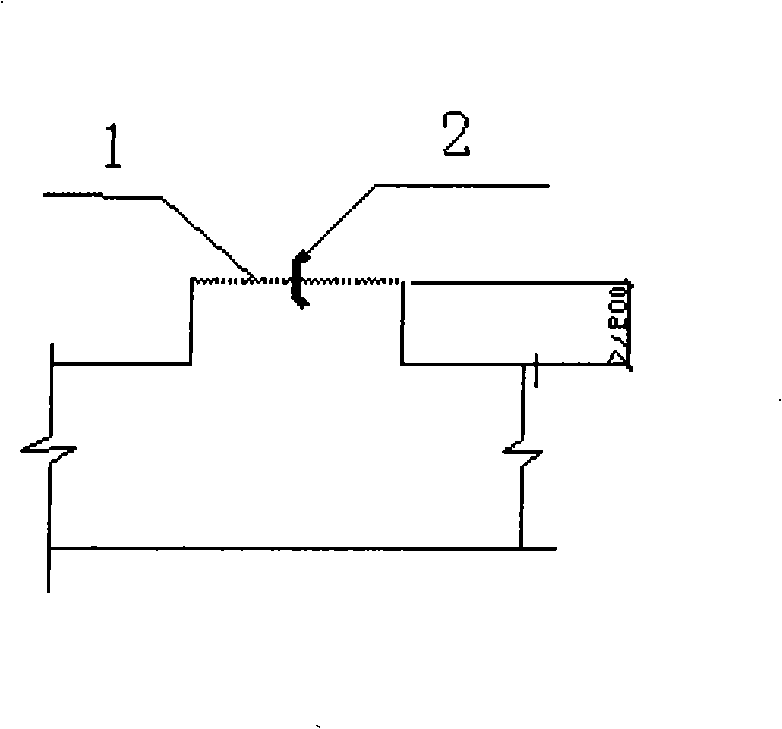

[0020] Step 1. The foundation of the rolling mill is an underground reinforced concrete box foundation. The general burial depth of the rolling mill foundation is -10.0m, and the local burial depth reaches -11.0m. The geometric dimensions of the foundation are 66.05m long and 44.55m wide. , the design level is C30, S6, and the thickness of the bottom plate is 1.5m. The foundation is deeply buried, the groundwater level is high, and the construction joints are difficult to deal with. According to the general situation of the project, the basement concrete construction joints are set at -8.2m, namely image 3 Middle construction joint 1c. In order to prevent leakage, the construc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com