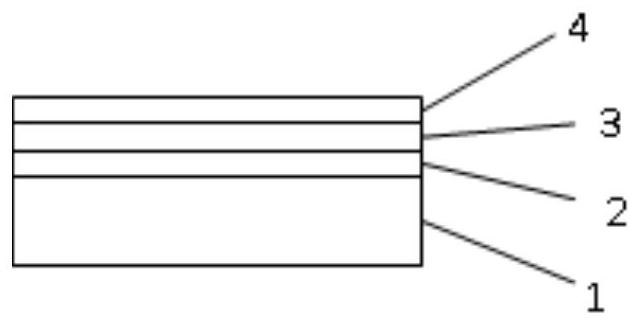

Anti-corrosion composite coating on surface of magnesium alloy and preparation method and application thereof

A composite coating and magnesium alloy technology, applied in the field of metal surface treatment, can solve the problems of unsustainable corrosion resistance, unstable composite coating structure, short service life, etc., and achieve low cost, excellent corrosion resistance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

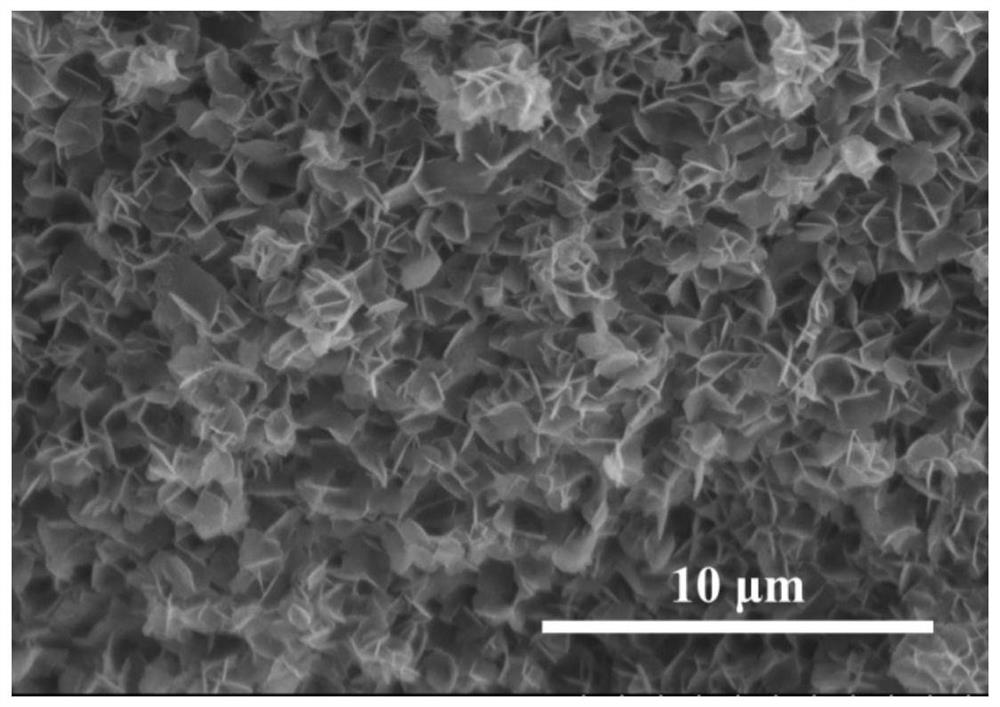

Embodiment 1

[0041] 1. The pretreatment step of magnesium alloy surface: comprise sandblasting and cleaning surface; Described sandblasting adopts the carborundum of 0.2mm, and the working air pressure of sandblasting machine is 0.6MPa, after sandblasting, ultrasonically cleans 10min through acetone solution again, Rinse the surface with deionized water and air-dry it, then weigh 4g NaOH and dissolve it in 100ml deionized water, place the sandblasted magnesium alloy in NaOH solution for 60 seconds, wash the surface with deionized water, and air-dry the surface to obtain pretreated magnesium alloy. alloy. Sandblasting and cleaning the surface to remove dust and oxide film impurities attached to the surface of the magnesium alloy; at the same time, the surface of the magnesium alloy after sandblasting has a certain roughness, which is conducive to providing chemical reaction active sites for subsequent in-situ growth. A square with a working area of 1x1cm is reserved on the surface of the ...

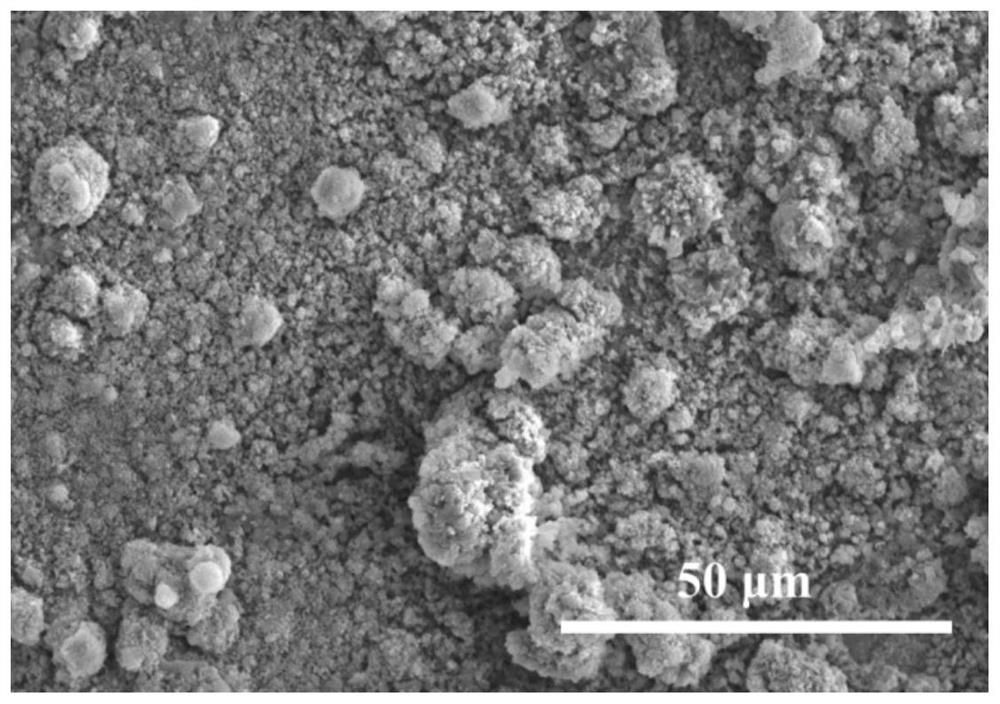

Embodiment 2

[0048] 1. The pretreatment step of magnesium alloy surface comprises sandblasting and cleaning surface; Described sandblasting adopts the corundum of 2.5mm, and the working air pressure of sandblasting machine is 0.55MPa, and after sandblasting, ultrasonically cleans 5min through acetone solution again, removes Rinse the surface with ionized water and air-dry, then weigh 6g NaOH and dissolve it in 100ml deionized water, then place the sandblasted magnesium alloy in NaOH solution for etching for 120s, wash the surface with deionized water, and air-dry the surface to obtain a pretreated magnesium alloy . Sandblasting and cleaning the surface to remove dust and oxide film impurities attached to the surface of the magnesium alloy; at the same time, the surface of the magnesium alloy after sandblasting has a certain roughness, which is conducive to providing chemical reaction active sites for subsequent in-situ growth. A square with a working area of 1x1cm reserved on the surface...

Embodiment 3

[0055] 1. The pretreatment step of magnesium alloy surface comprises sandblasting and cleaning surface; Described sandblasting adopts the carborundum of 0.22mm, and the working air pressure of sandblasting machine is 0.85MPa, and after sandblasting, ultrasonically cleans 10min through acetone solution again, removes Rinse the surface with ionized water and air-dry, then weigh 6g NaOH and dissolve it in 100ml deionized water, place the magnesium alloy after sandblasting in NaOH solution for etching for 80s, wash the surface with deionized water, and air-dry the surface to obtain a pretreated magnesium alloy. Sandblasting and cleaning the surface to remove dust and oxide film impurities attached to the surface of the magnesium alloy, while the surface of the magnesium alloy after sandblasting has a certain roughness is conducive to providing chemical reaction active sites for subsequent in-situ growth. The reserved working area on the surface of the magnesium alloy is 1x1cm squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com