Vacuum environment control box for preparing nano fluid

A technology of vacuum environment and operation box, applied in the direction of manufacturing tools, manipulators, laboratory utensils, etc., can solve the problems of oxidation and affect the performance of nanofluids, and achieve the effect of comfortable operation and observation, large effective operation space, and good performance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

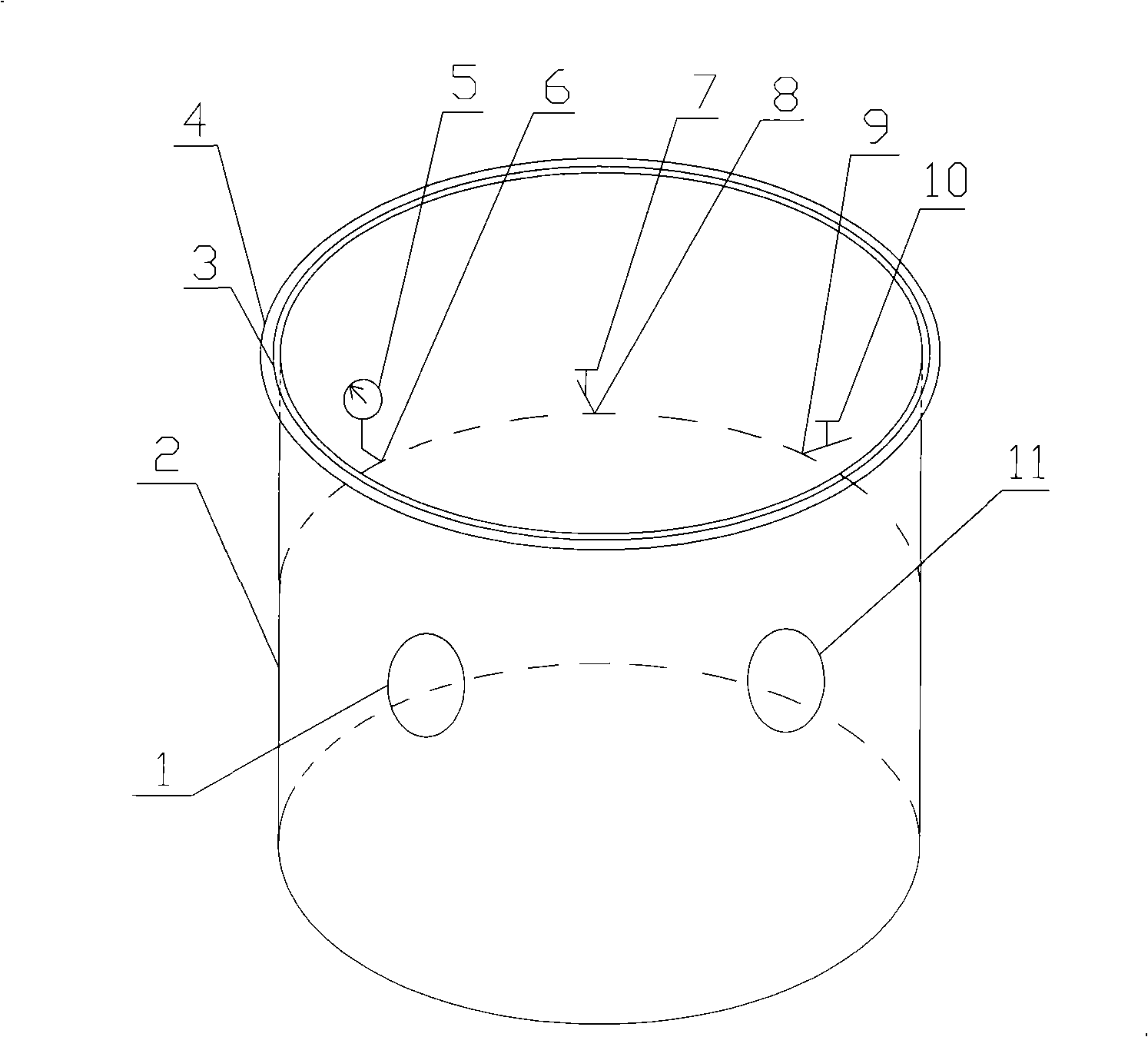

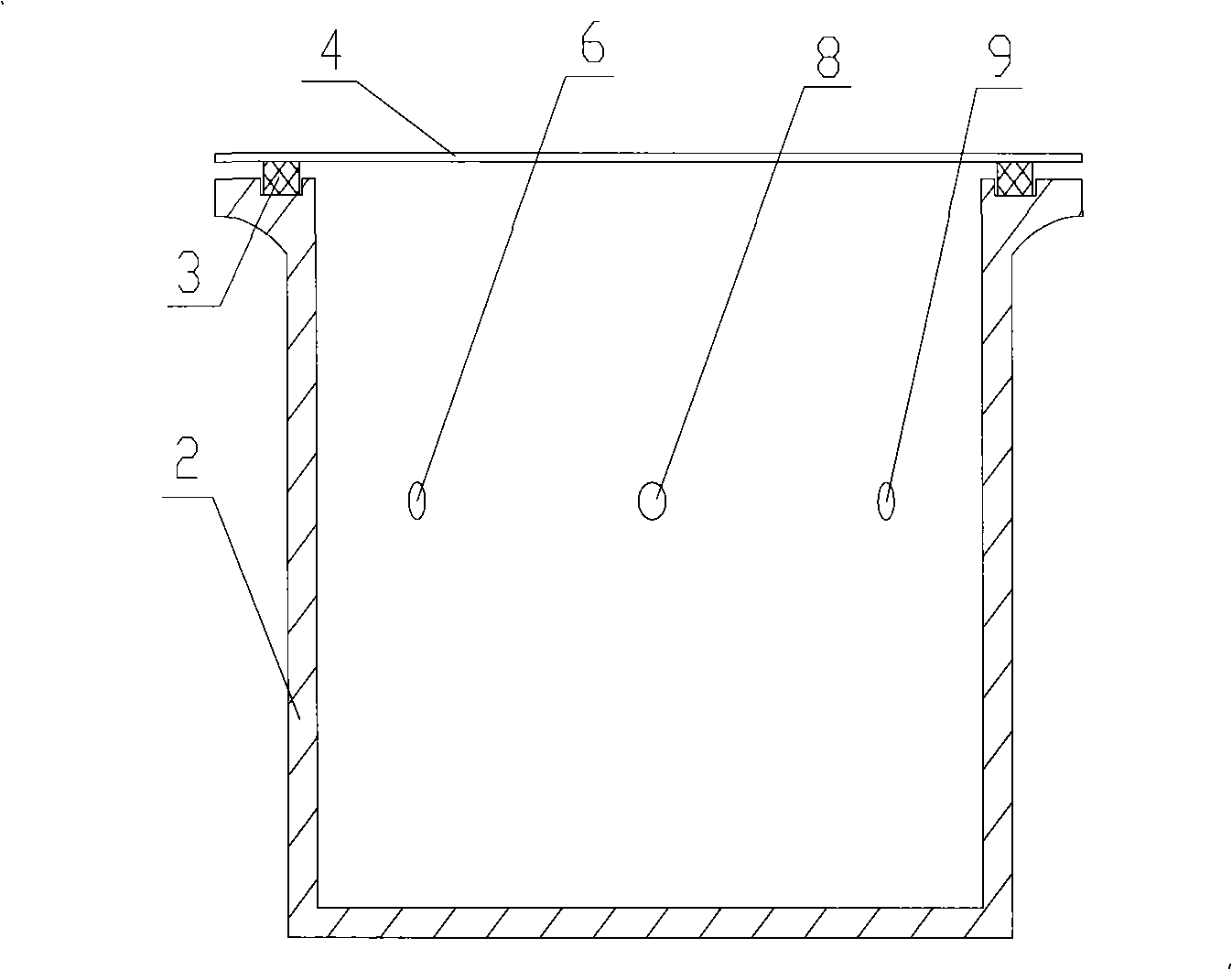

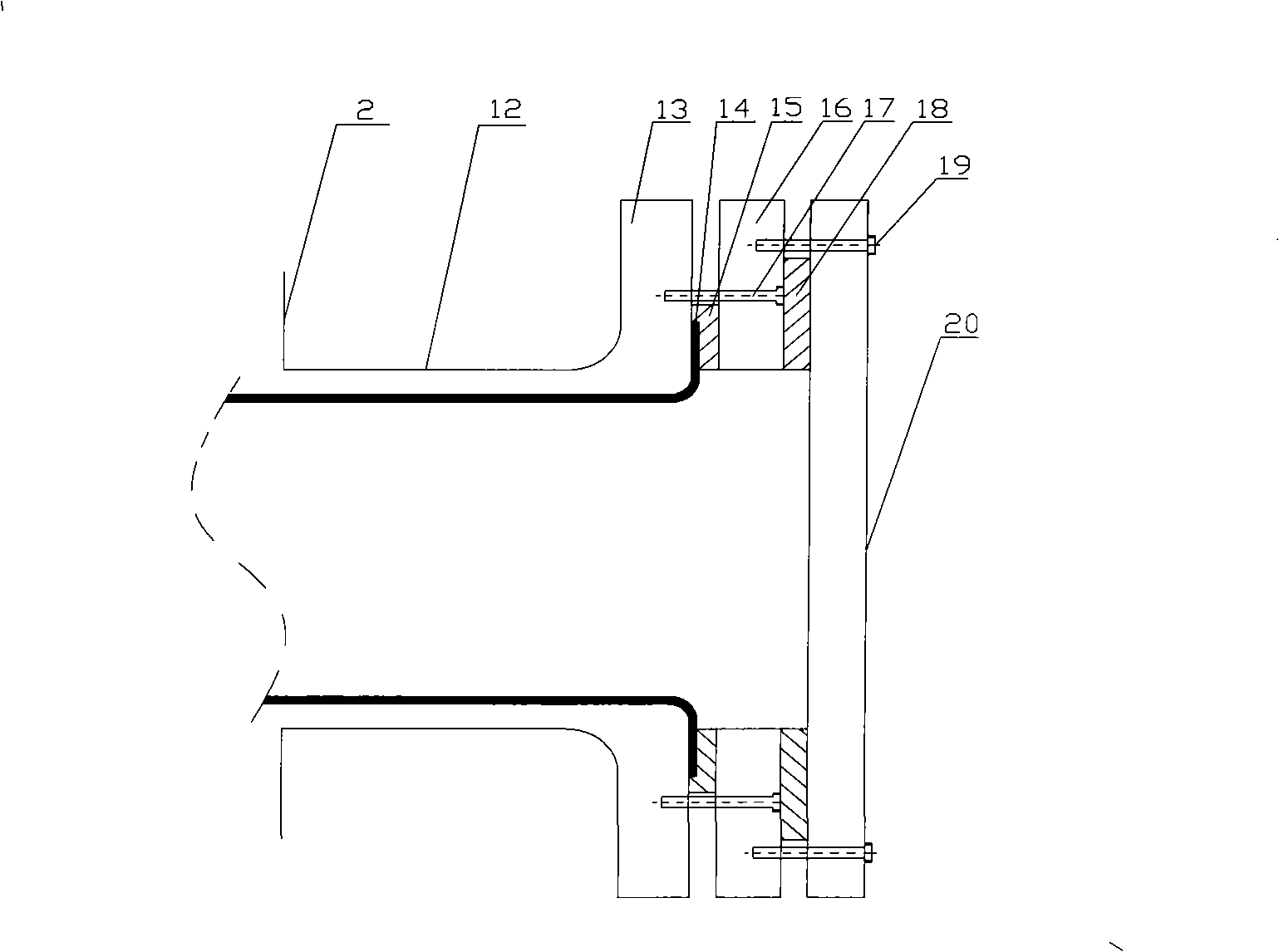

[0012] Such as figure 1 The overall structure diagram of the vacuum environment operation box for nanofluid preparation: the operation box is mainly composed of a circular groove-shaped box body 2, a tempered glass cover plate 4, a sealing gasket 3, an air inlet 8, an air inlet 9, a vacuum pressure gauge interface 6, a vacuum Pressure gauge 5, vacuum valves 7, 10, operating ports 1, 11, rubber gloves 14, steel ring 16, operating port sealing cover 20, and compression bolt 17 are combined.

[0013] The upper opening of the circular groove-shaped box body 2, the sealing gasket 3 is bonded in the opening groove of the upper part of the box body 2, the tempered glass cover plate 4 is placed on the upper opening of the box body, and the sealing gasket is pressed to close it, and it is also used as a window Observe the operation in the box, if attached fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com