Fuzzy control method of TIG welding source ring closure

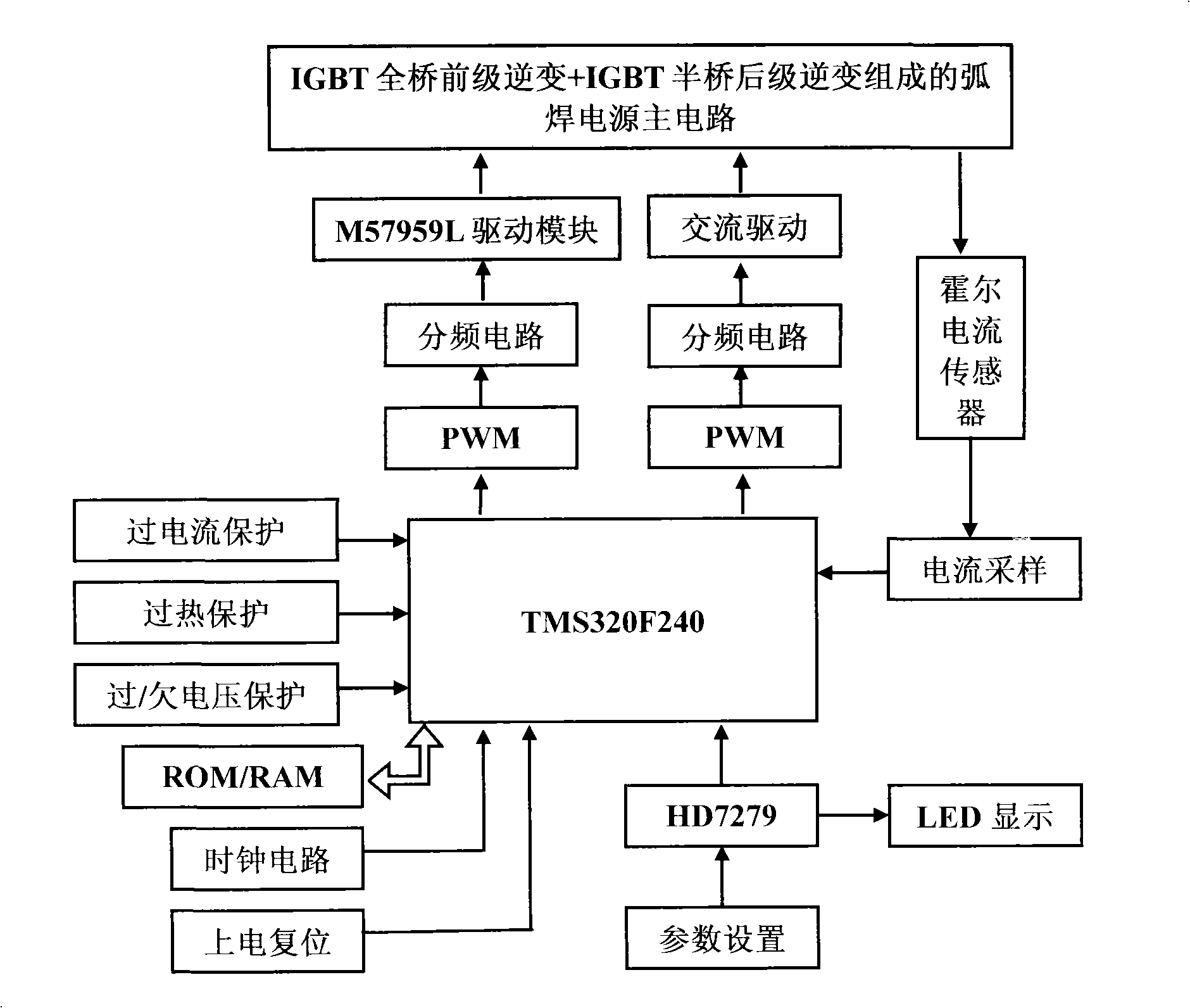

A fuzzy control algorithm and fuzzy control technology, applied in welding equipment, control/regulation systems, manufacturing tools, etc., can solve the problem of welding current and voltage deviation from the stable working point, achieve good control effect, reduce peripheral devices, and respond quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The closed-loop fuzzy control method of the TIG welding power source of the present invention will be described in further detail below.

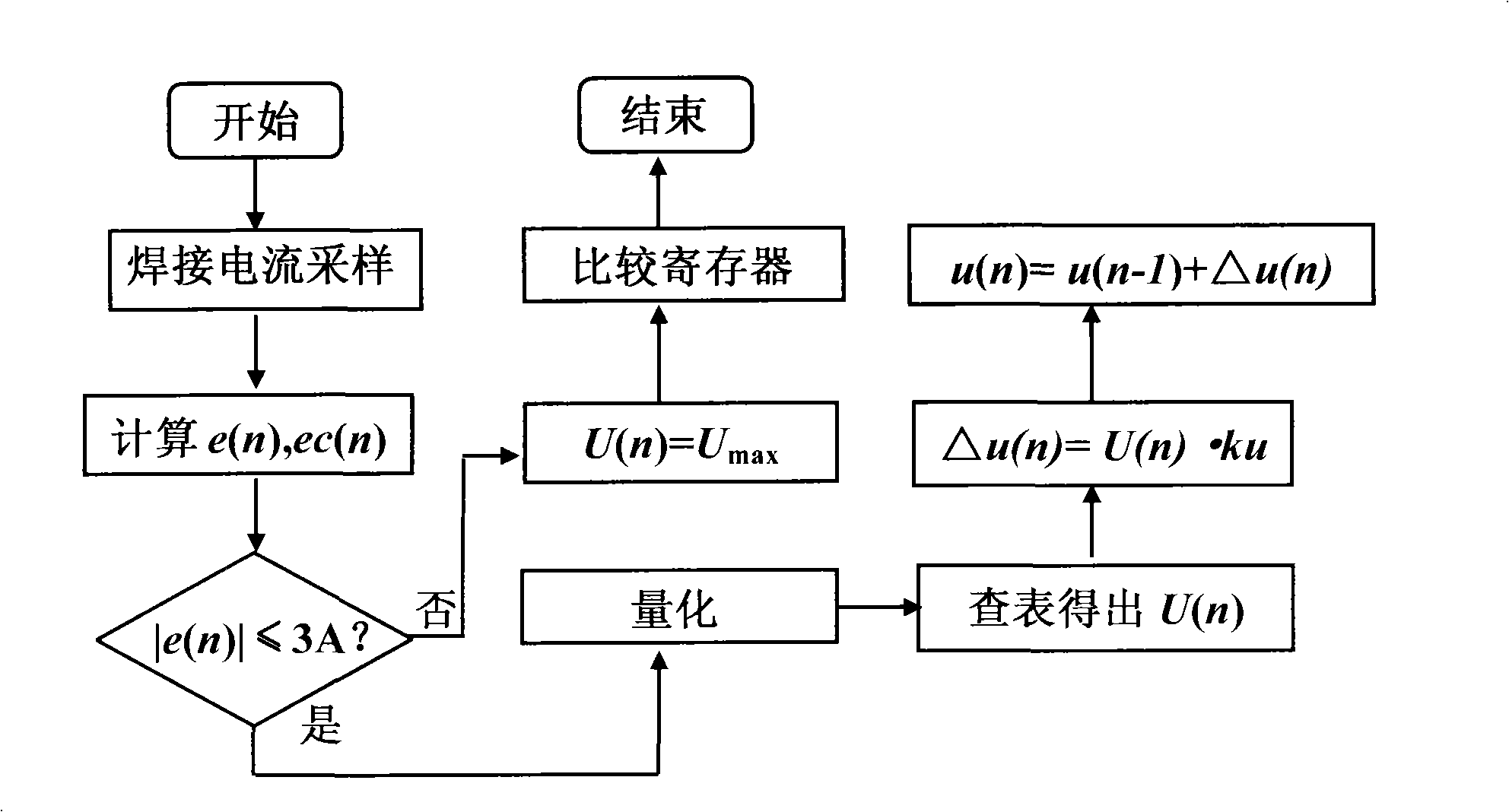

[0018] See image 3 As shown, the closed-loop fuzzy control method of the TIG welding power source of the present invention includes the steps:

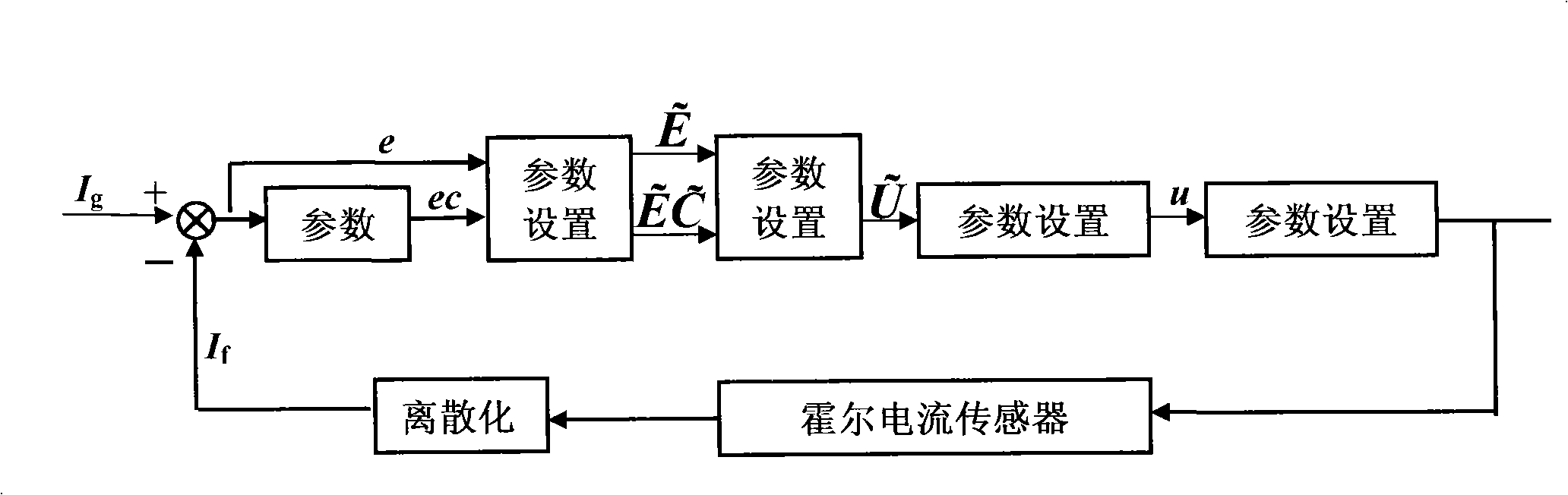

[0019] 1) The arc current is detected by the current sampling unit and converted into the corresponding voltage signal. After filtering and limiting, the arc current enters the A / D conversion channel of the DSP and converted into a digital discrete value I f , CPU comparison I f And preset welding current variable I g , Get the deviation e and the deviation change rate ec; 2) DSP runs the fuzzy control algorithm program according to e and ec, finds the control signal u needed to eliminate e, and transmits it to the built-in PWM module of the DSP to directly control the PWM output by the DSP Pulse width to control the output current.

[0020] In a specific embodiment of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com