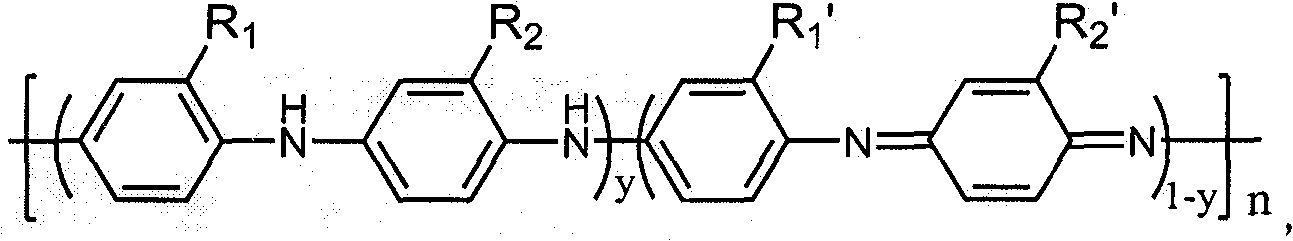

UV curing polyaniline anti-corrosive paint and preparation thereof

A technology of anti-corrosion coatings and polyaniline, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of metal anti-corrosion application research and product reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

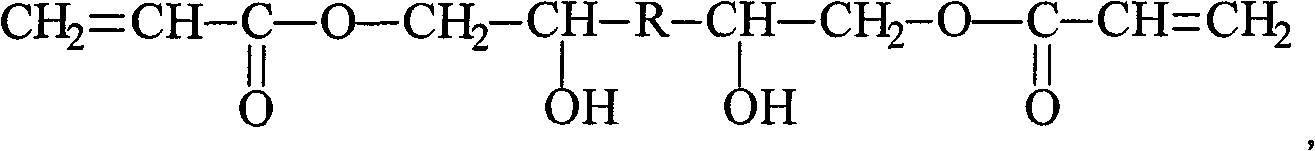

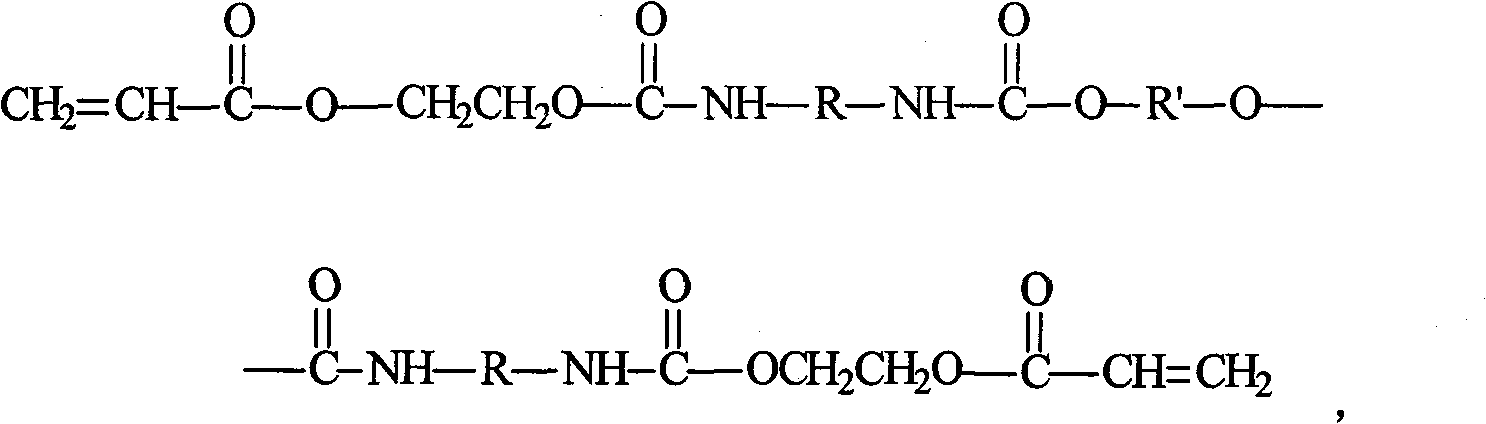

Method used

Image

Examples

Embodiment 1

[0043] Weigh 89 grams of epoxy acrylate and 40 grams of hydroxyethyl acrylate respectively, put them into a laboratory sand mill tank, add 2 grams of polyaniline under stirring, and stir for 0.5 hour. After stirring, add dispersant BYK163: 0.5g, talcum powder 15g, calcium carbonate 30g, precipitated barium sulfate 15g, leveling agent BYK371: 0.5g, 2-hydroxy-2-methyl-1-phenylacetone 8 g, stirred at a speed of 2500 rpm for 3 hours, sanded for 1 hour, and filtered with a 200-mesh filter cloth.

[0044] Spray the paint on a polished, degreased, and derusted metal steel plate, level it at 60°C for 2 minutes, irradiate with 3kw ultraviolet light, and cure for 30 seconds. After the paint film is cured, measure its performance. The results are shown in Table 1.

Embodiment 2

[0046] Weigh 80 grams of epoxy acrylate and 42 grams of cyclohexyl acrylate respectively, put them into a sand mill tank, add 10 grams of polyaniline under stirring, and stir for 1 hour. After stirring, add dispersant BYK163: 1g, talcum powder 15g, calcium carbonate 30g, precipitated barium sulfate 15g, leveling agent BYK371: 1g, 2-hydroxy-2-methyl-1-phenylacetone 6 g, stirred at a speed of 2500 rpm for 0.5 hour, sanded for 5 hours, and filtered with a 200-mesh filter cloth.

[0047] Spray the paint on a polished, degreased, and derusted metal steel plate, level it at 60°C for 2 minutes, irradiate with 3kw ultraviolet light, and cure for 30 seconds. After the paint film is cured, measure its performance. The results are shown in Table 1.

Embodiment 3

[0049] Weigh 106 grams of epoxy acrylate and 50 grams of isobornyl acrylate respectively, put them into a sand mill tank, add 20 grams of polyaniline under stirring, and stir for 2 hours. Add dispersant BYK163: 3 grams, talc powder 2 grams, calcium carbonate 5 grams, precipitated barium sulfate 3 grams, leveling agent BYK371: 3 grams, 1-hydroxycyclohexyl benzophenone 8 grams, 2500 rpm Stir at a speed of 1 / min for 1 hour, sand mill for 10 hours, and filter with a 200-mesh filter cloth.

[0050] Spray the paint on the polished, degreased, and derusted metal steel plate, level it at 60°C for 2 minutes, irradiate with 3kw ultraviolet light, and cure for 30 seconds. After the paint film is cured, measure its performance. The results are shown in Table 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com