Polishing solution for polishing low dielectric material

A low-dielectric material and polishing liquid technology, applied in the field of polishing liquid, can solve the problems of copper CMP surface defects, easy to produce scratches, etc., and achieve the effect of improving electrical performance, reducing sawtooth, and enhancing protection

Inactive Publication Date: 2009-04-15

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF4 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Since copper is a chemically and electrochemically active metal, the copper surface will be corroded under the chemical action of the polishing solution, and copper is relatively "soft" and prone to scratches, so copper CMP is prone to surface defects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

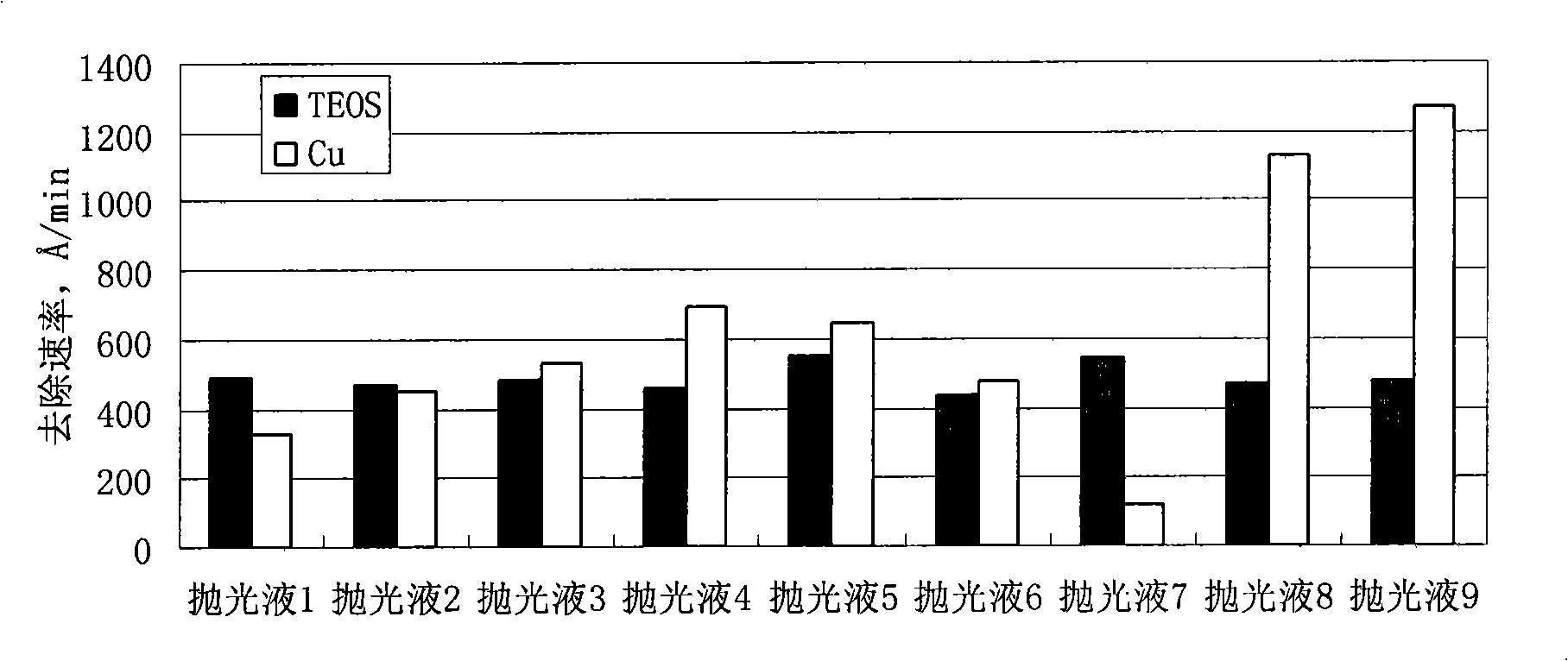

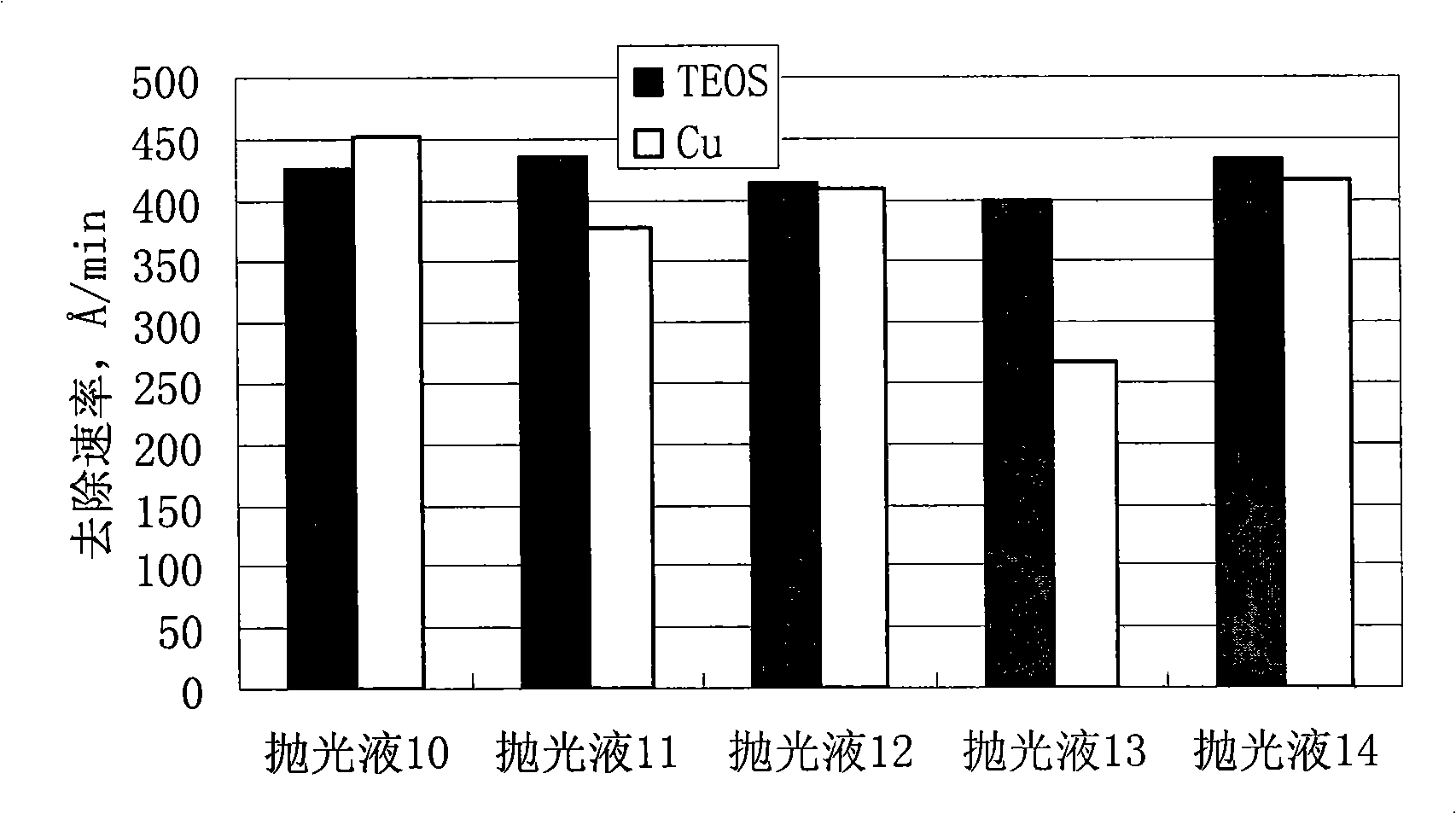

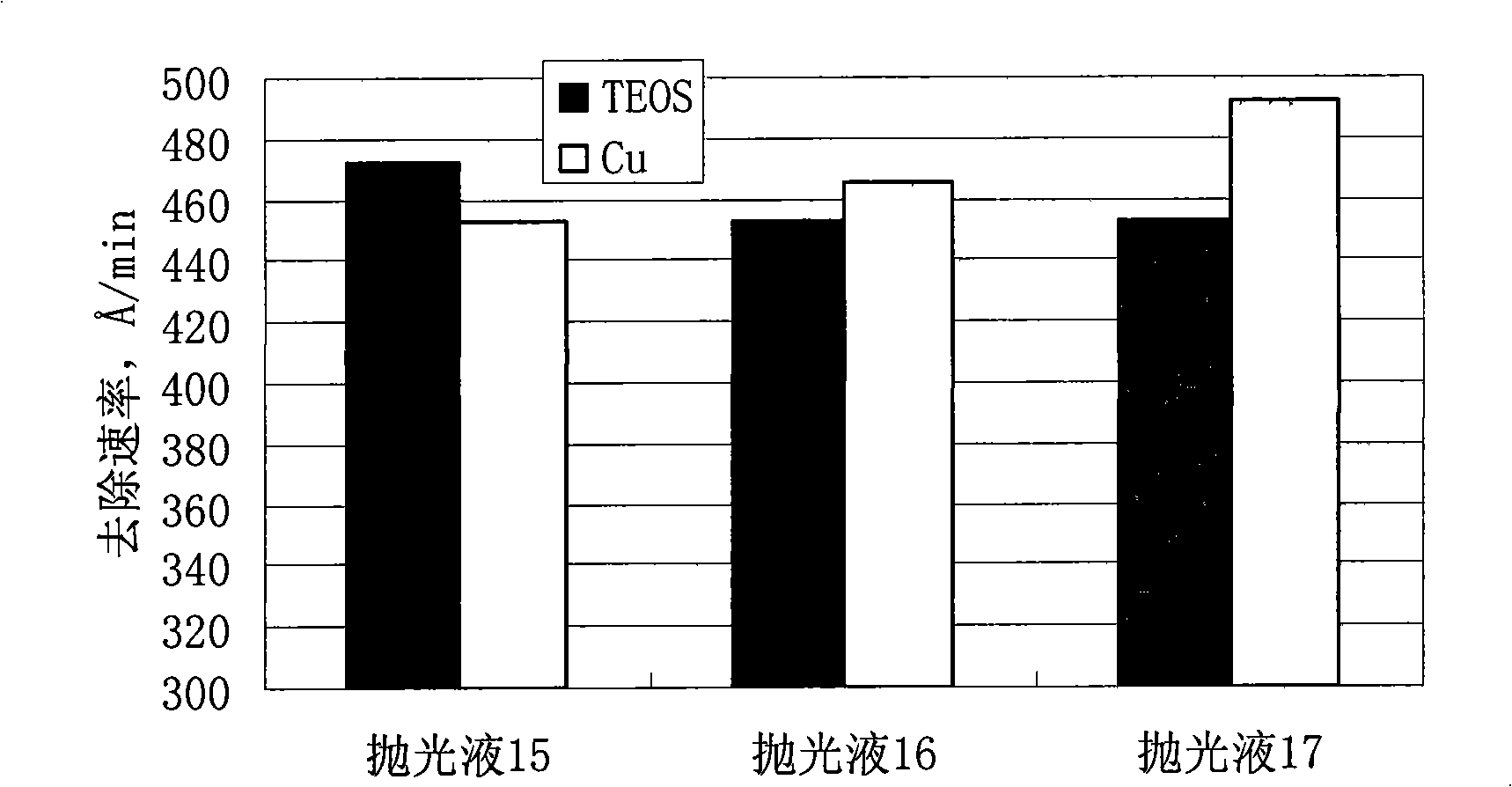

Embodiment 1

[0024] Silica (70 nm) 4%, benzotriazole 0.1%, 5-aminotetrazole 0.05%, pH=3.0.

Embodiment 2

[0026] Silica (70nm) 4%, tartaric acid 0.4%, benzotriazole 0.1%, 1,2,4 triazole 0.05%, pH=3.0.

Embodiment 3

[0028] Silicon dioxide (70nm) 4%, 5-aminotetrazole 0.1%, 5-methyltetrazolium 0.05%, hydrogen peroxide 0.3%, pH=3.0.

[0029] Example 3

[0030] Silica (70nm) 4%, 5-aminotetrazole 0.1%, 5-methyltetrazolium 0.05%, polyacrylic acid anion surfactant 0.2%, pH=3.0.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses polishing liquid for polishing low dielectric materials, which contains silicon dioxide and water; and the polishing liquid is characterized in that the polishing liquid further contains a mixed corrosion inhibitor. The polishing liquid can enhance the protection of a Cu thin line, significantly reduce the defects of saw teeth, dents, scratches, erosion, scratches, and the like, and improve the electrical performance of a polishing chip.

Description

technical field [0001] The invention relates to a polishing liquid in a semiconductor manufacturing process, in particular to a polishing liquid for polishing low dielectric materials. Background technique [0002] As the device size of integrated circuits shrinks and the number of wiring layers increases, the width of metal lines narrows, which leads to an increase in the resistivity of metal wiring and an increase in the RC delay of the circuit, which seriously restricts the performance of integrated circuits. Because copper has better electromigration resistance and high conductivity than aluminum, it has replaced aluminum as the wire material for deep submicron integrated circuits. Currently, the damascene process using copper chemical mechanical polishing (CMP) is the only mature and applied wiring technology for copper interconnect lines. As a key planarization technology for ULSI multilayer wiring, copper CMP has a great influence on the development of ULSI. The cop...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02

Inventor 陈国栋王淑敏荆建芬宋伟红徐春

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com