Fire-retardant polyacrylacid ester adhesive and preparation thereof

A polyacrylate and acrylate technology, applied in the direction of adhesives, ester copolymer adhesives, adhesive types, etc., can solve the problems of uneven mixing of flame retardants, destroying the balance system, and decreasing bonding performance. , to achieve the effect of simple processing equipment and process, wide application and improved bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

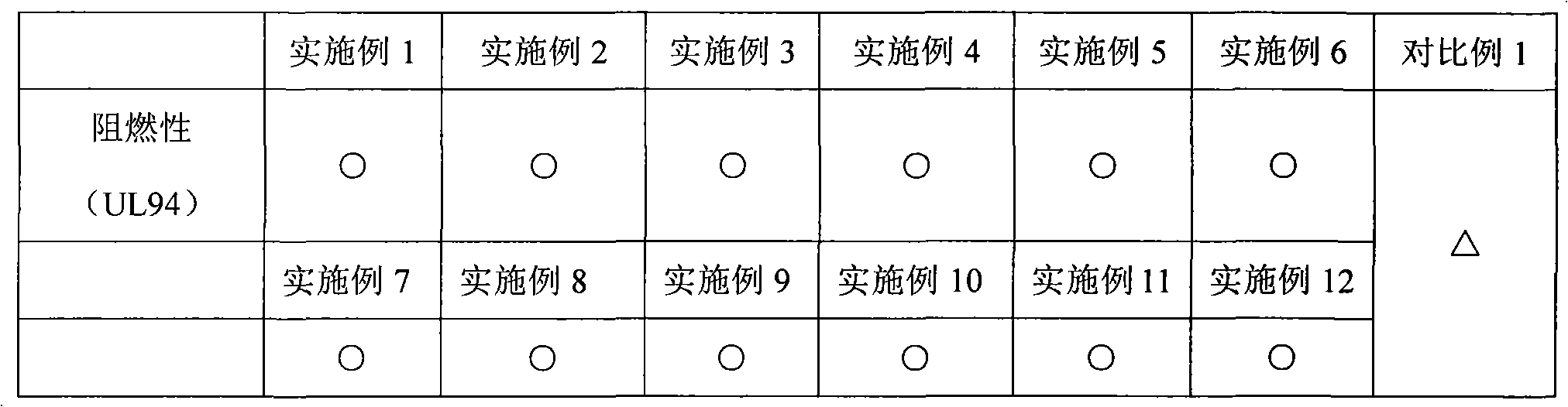

Examples

Embodiment 1

[0039] In a stirred reactor, add the monomer blend with the following mass percentage, heat to a constant temperature of 50° C. to 60° C., and react continuously for 4 hours to obtain polyacrylate emulsion 1.

[0040] Butyl acrylate

Embodiment 2

[0042] A monomer mixture having the following mass percentages was added into the reactor, and polyacrylate emulsion 2 was obtained under the same reaction conditions as in Example 1.

[0043] Butyl acrylate

Embodiment 3

[0045] A monomer mixture having the following mass percentages was added into the reactor, and polyacrylate emulsion 3 was obtained under the same reaction conditions as in Example 1.

[0046] Butyl acrylate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com