High polymer quenching solution, preparation thereof and quenching method for steel products

A technology of quenching liquid and polymer, applied in the field of polymer quenching liquid, can solve problems such as inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also provides a method for preparing a polymer quenching liquid, comprising (a) providing nano-inorganic powder, and uniformly dispersing the nano-inorganic powder in water, and (b) adding a water-soluble polymer to the nano- Inorganic powder in water to form polymer quenching liquid. In addition, in step (a), a heating procedure may be performed to accelerate the dispersion of the inorganic powder in water.

[0024] In another embodiment, it also includes adding functional additives such as anti-corrosion to the high-fraction quenching liquid after step (b), so as to increase the performance of the quenching liquid.

[0025] The present invention also provides a method for quenching steel, comprising (a) providing steel, (b) heat-treating the steel, and (c) placing the steel in the quenching liquid of the present invention to perform a quenching procedure, in which In the quenching procedure, the maximum cooling rate (maximum cooling rate) of the...

Embodiment 1

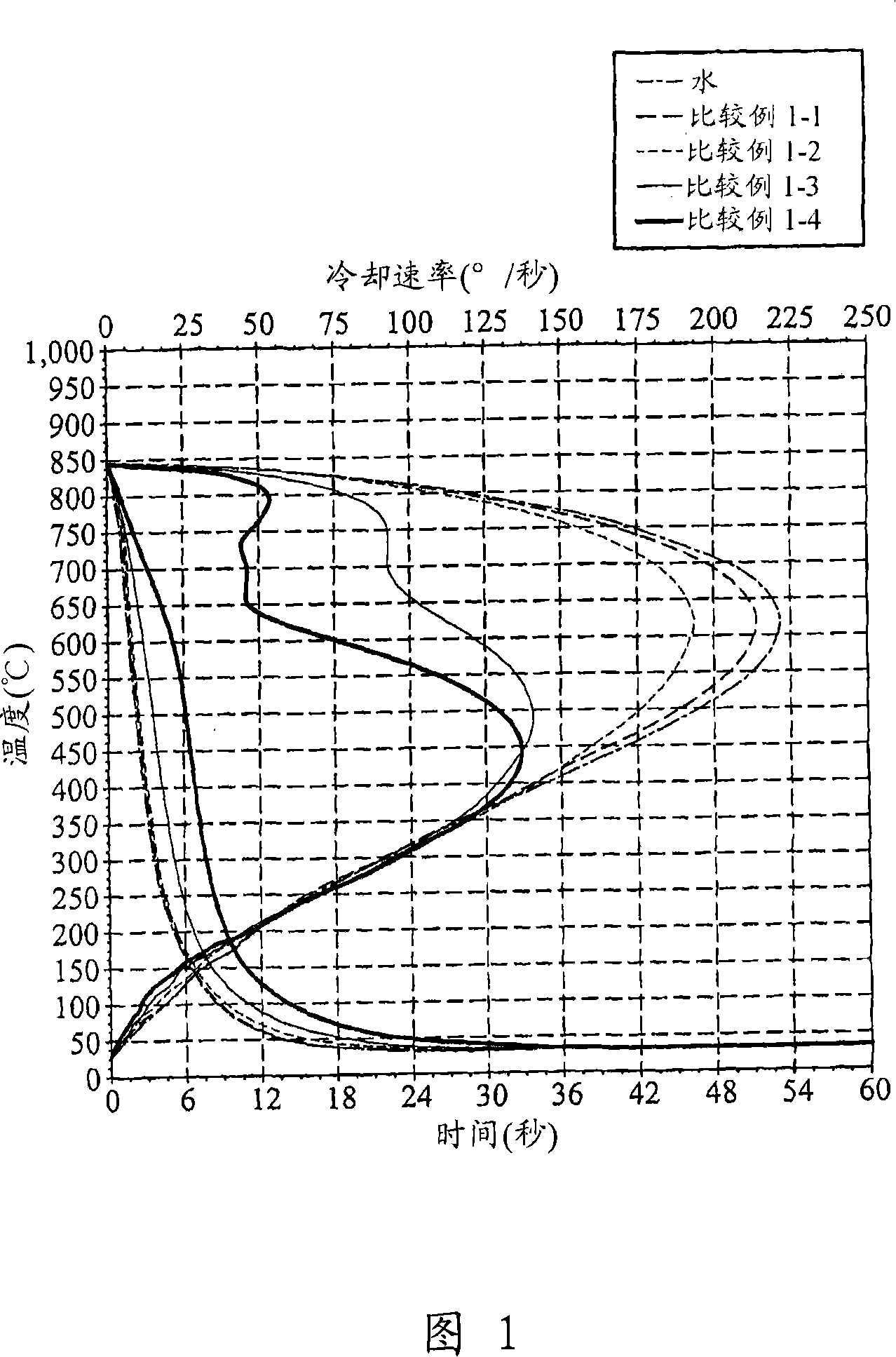

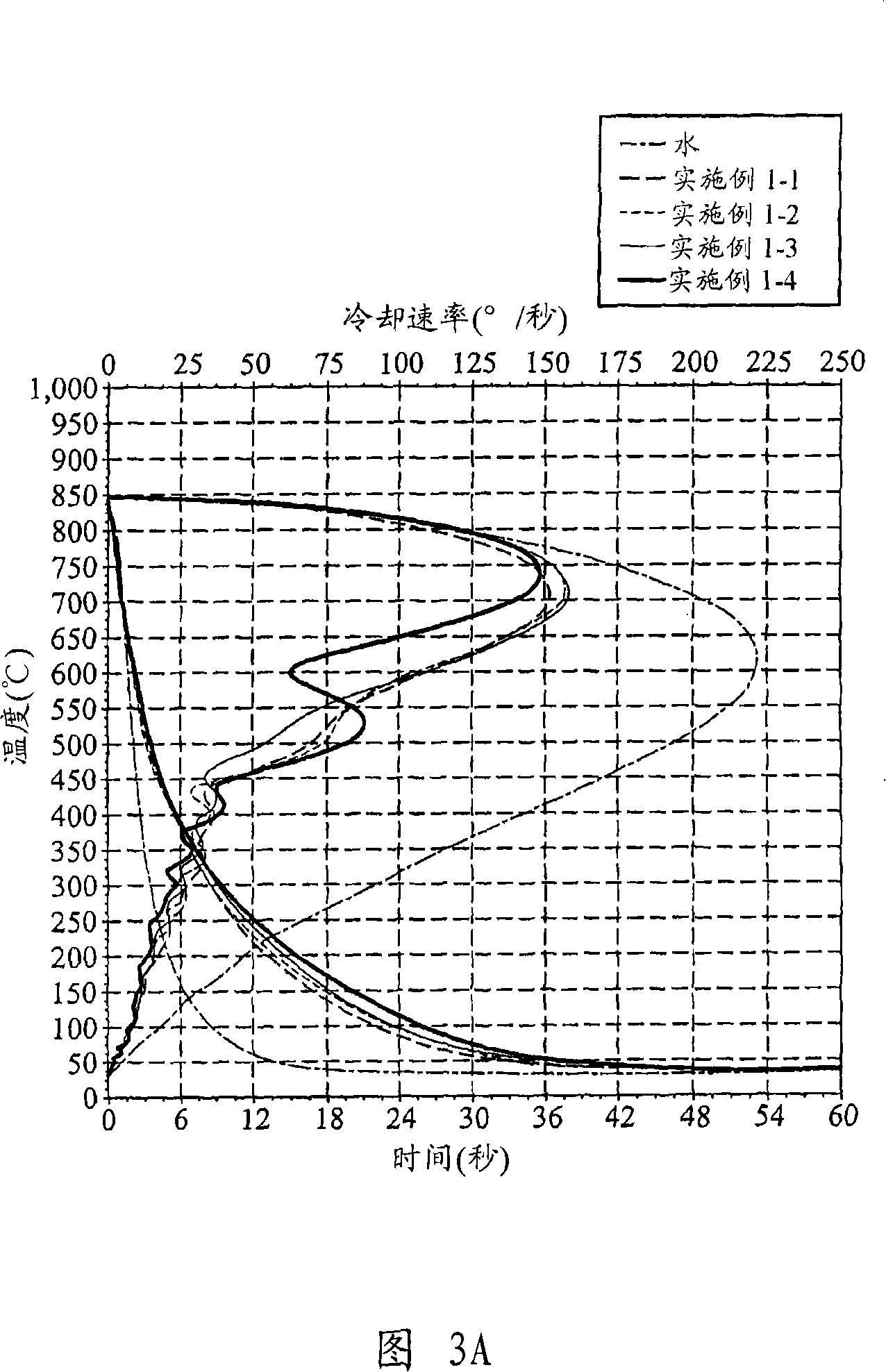

[0041] Embodiment 1. Influence of inorganic powder on quenching curve

[0042] The process of this example is the same as that of Comparative Example 1, except that the quenching liquid is changed to contain 15wt% SQ1500 polymer and 5wt%, 10wt%, 15wt%, 20wt% and 25wt% inorganic powder PK812 respectively. Please refer to Figure 3A-3B And Table 3, the maximum cooling rate and the quenching rate at 300°C will decrease with the increase of inorganic powder, and the temperature at start of convection will increase from 420°C to above 670°C, and the maximum cooling The rate of temperature will increase with the increase of inorganic powder.

[0043] Table four, the quenching characteristics of the present embodiment quenching liquid

[0044]

[0045]

[0046]

Embodiment 2

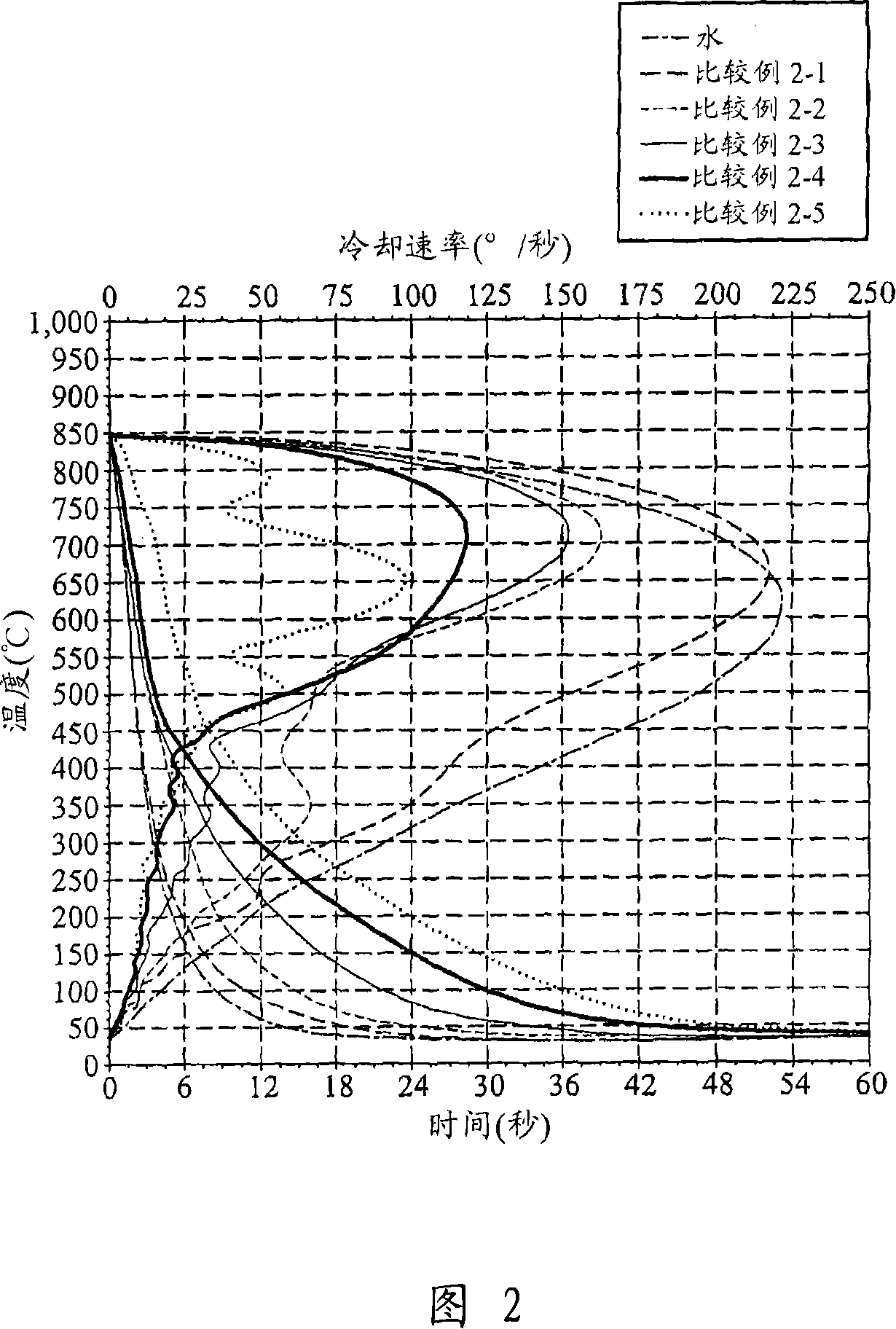

[0047] Example 2. Influence of Inorganic Powder and High Molecular Content on Quenching Curve

[0048] The process of this embodiment is the same as that of Comparative Example 1, except that the quenching liquid is changed to contain 15, 20 and 25 wt% of SQ1500 polymer and 0.5 wt% and 1.0 wt% of inorganic powder PK812 respectively. Please refer to Figure 4 And Table 4, the maximum cooling rate and the quenching rate at 300°C will decrease with the increase of inorganic powder PK812, and the temperature of the maximum cooling rate will increase with the increase of inorganic powder.

[0049] Table four, the quenching characteristics of the present embodiment quenching liquid

[0050]

[0051]

[0052]

[0053] Analysis of actual steel grades

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com