Method for improving stress corrosion resistance of integral forging low-voltage rotor of nuclear steam turbine

A low-pressure rotor, corrosion-resistant technology, applied in furnace types, furnaces, heat treatment equipment, etc., can solve problems affecting the service life of nuclear power rotors, nuclear power steam turbine safety, stress corrosion cracking, etc., and achieve the effect of meeting stress corrosion resistance conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

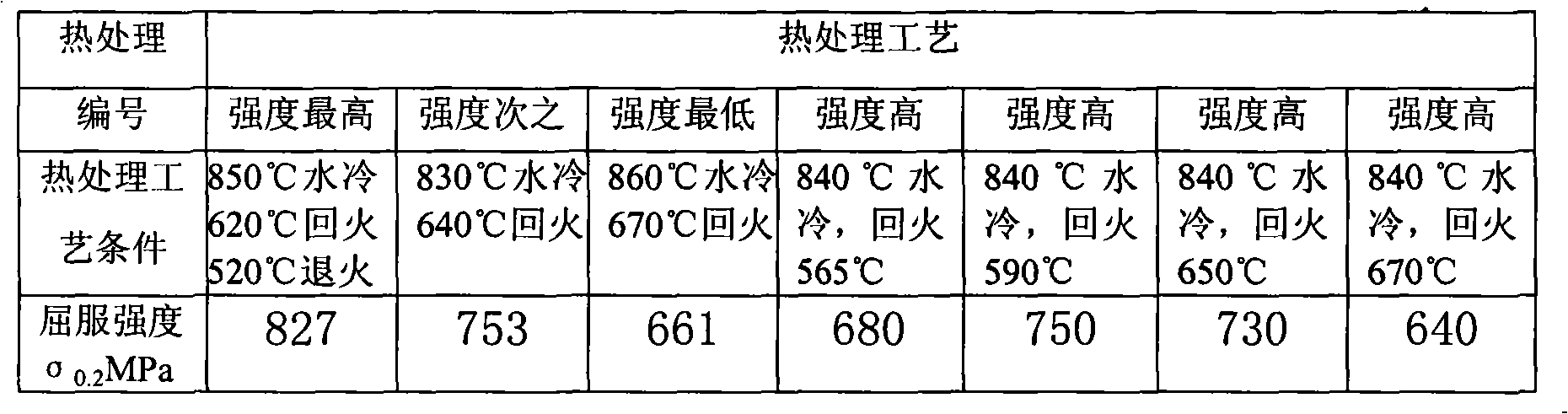

[0018] Heating the 30Cr2Ni4MoV steel material to the austenitization temperature of 850°C, cooling with water, and tempering temperature at 620°C can obtain the highest strength of the steel material, with a yield strength of 827MPa.

Embodiment 2

[0020] The 30Cr2Ni4MoV steel material is heated to the austenitization temperature of 830°C, cooled with water, and the tempering temperature is 640°C, and the yield strength of the steel material is 753MPa.

Embodiment 3

[0022] The 30Cr2Ni4MoV steel material is heated to the austenitization temperature of 860°C, cooled with water, and the tempering temperature is 670°C, and the yield strength of the steel material is 661MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com