Combined sand-washing well repairing machine

A technology of workover rig and sand flushing, applied in flushing wellbore, drilling equipment, wellbore/well components, etc., can solve the problems of non-adjustable angle, narrow adaptation range, low efficiency, etc., to achieve improved efficiency, stable pressure, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

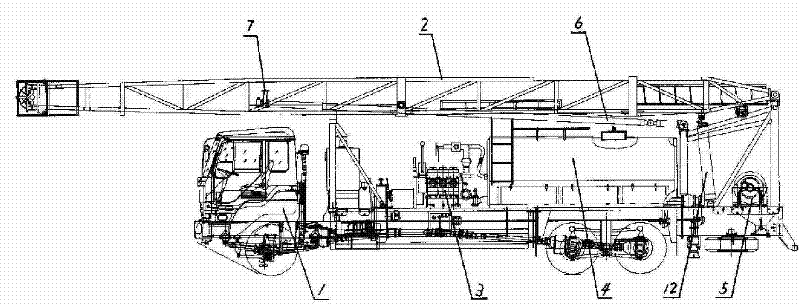

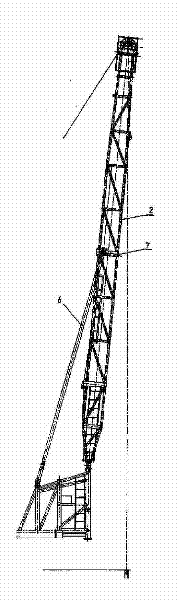

[0013] see figure 1 , 2 The combined sand washing and workover rig includes a vehicle-mounted chassis 1 and a vehicle-mounted derrick 2 . A sand washing pump 3 , a solution tank 4 and a winch 5 are installed on the vehicle chassis 1 , and the sand washing pump 3 is connected to the solution tank 4 . The winch 5 is mainly used for hoisting the screw pump rotor.

[0014] The vehicle-mounted chassis 1 is provided with a diagonal tie rod 6, and the diagonal stay rod 6 is locked and connected with the cylinder 7 (preferably pneumatic or oil-driven) on the derrick 2 top.

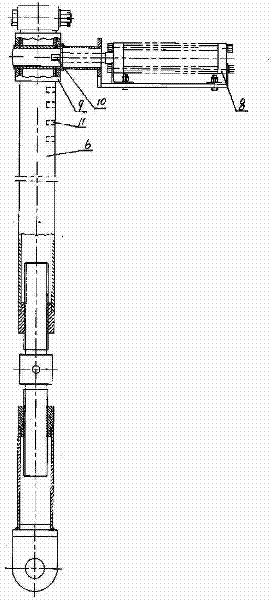

[0015] see image 3 , the oblique tie rod 6 and the cylinder block 8 are slidingly connected through the sliding sleeve 9, the sliding sleeve 9 is fixedly connected with the cylinder block 8, and the cylinder block 8 is fixedly connected with the derrick 2. The piston rod 10 in the cylinder 7 is plugged into the jacks 11 arranged at intervals on the diagonal stay rod 6 respectively. When the piston rod 10 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com