Method for moving belt oil pumping machine

A technology of pumping units and belts, which is applied in the direction of machines/engines, mechanical equipment, earthwork drilling, etc., can solve the problems of insufficient moving distance and easy deviation of pumping units, etc., and achieve stable movement, fast and convenient use, and convenient manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

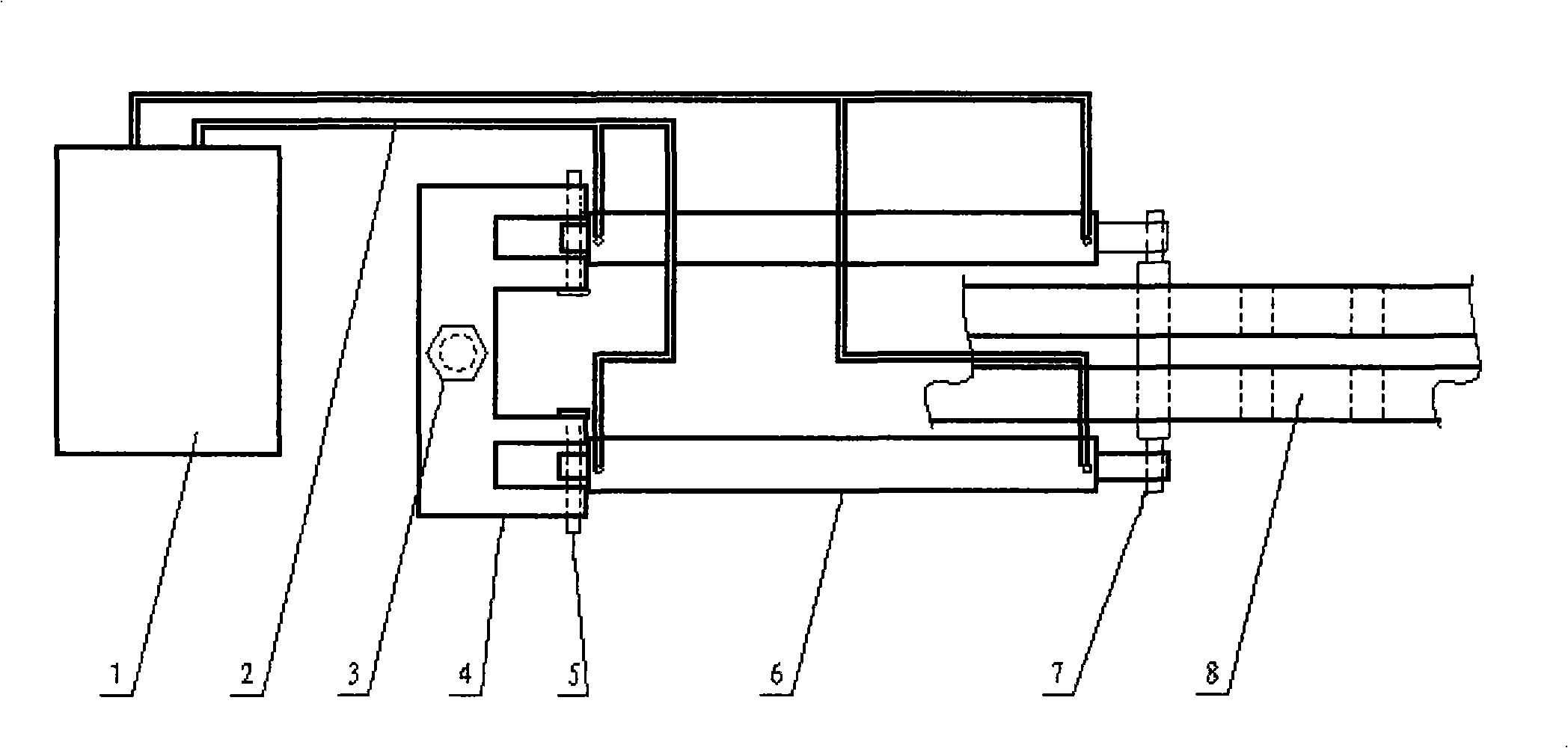

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The method of moving the belt pumping unit consists of a hydraulic station 1, a high-pressure hose 2, a double-acting hydraulic cylinder 6, a hydraulic cylinder fixing seat 4, an anchor bolt 3, a pin shaft 5, and a horizontal shaft 7 for moving the machine. The hydraulic station 1 passes through The high-pressure rubber hose 2 communicates with the double-acting hydraulic cylinder 6; the hydraulic cylinder fixing seat 4 is fixed on the ground by the anchor bolt 3, one end of the two hydraulic cylinders 6 is connected with the hydraulic cylinder fixing seat 4 through the pin shaft 5, and the other end is connected with the moving machine Horizontal shaft 7 links to each other, and there are two rows or three rows of moving machine holes on pumping unit base 8, and moving machine horizontal shaft 7 is fixed on the pumping unit base 8 by moving mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com