Seal device for ultra-high pressure contain

A sealing device, ultra-high pressure technology, applied in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of short service life, high pressure, falling off, etc., and achieve long service life, moderate hardness, and economical cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention provides a sealing device for an ultra-high pressure vessel, and the present invention will be further described below through the description of the drawings and specific implementation methods.

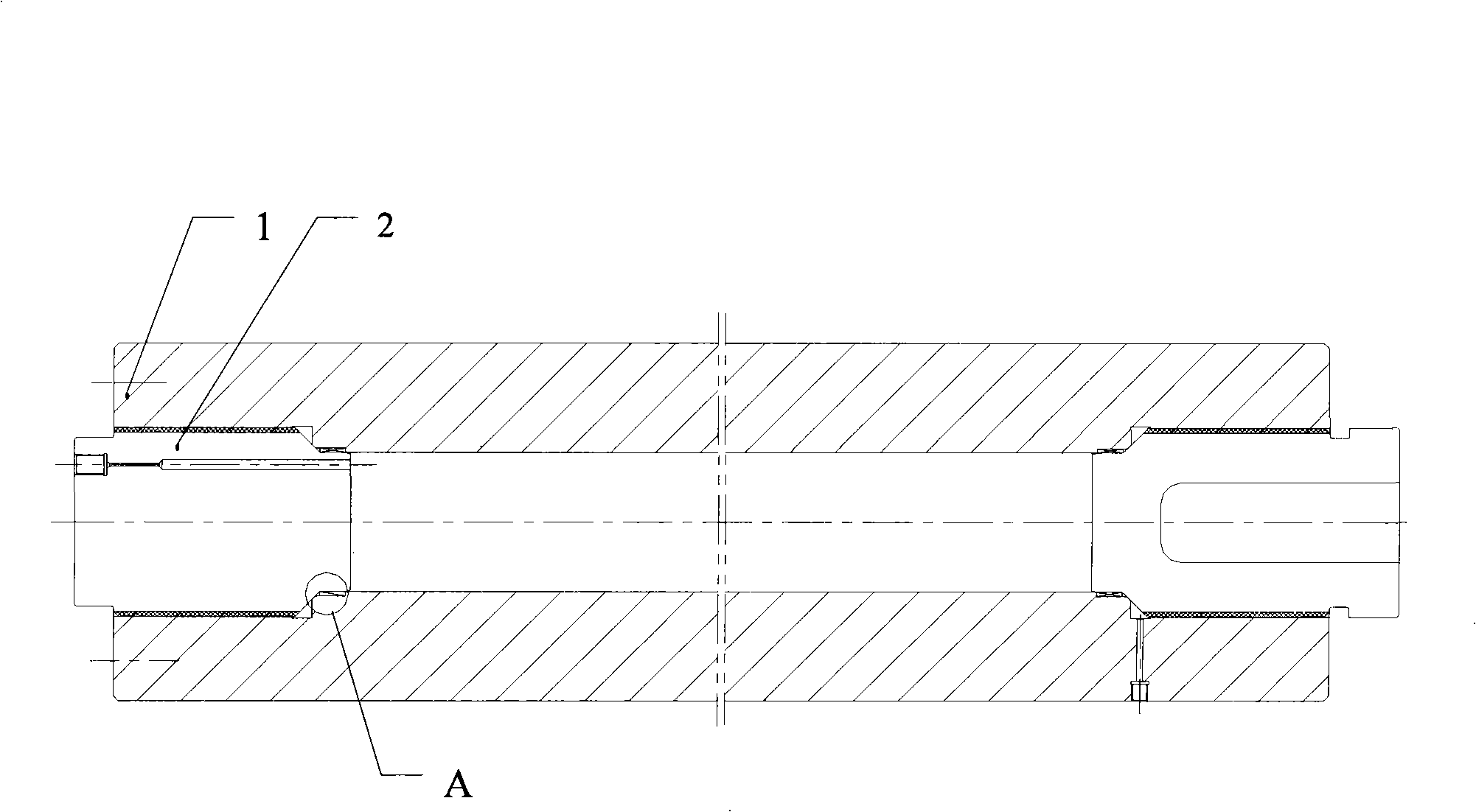

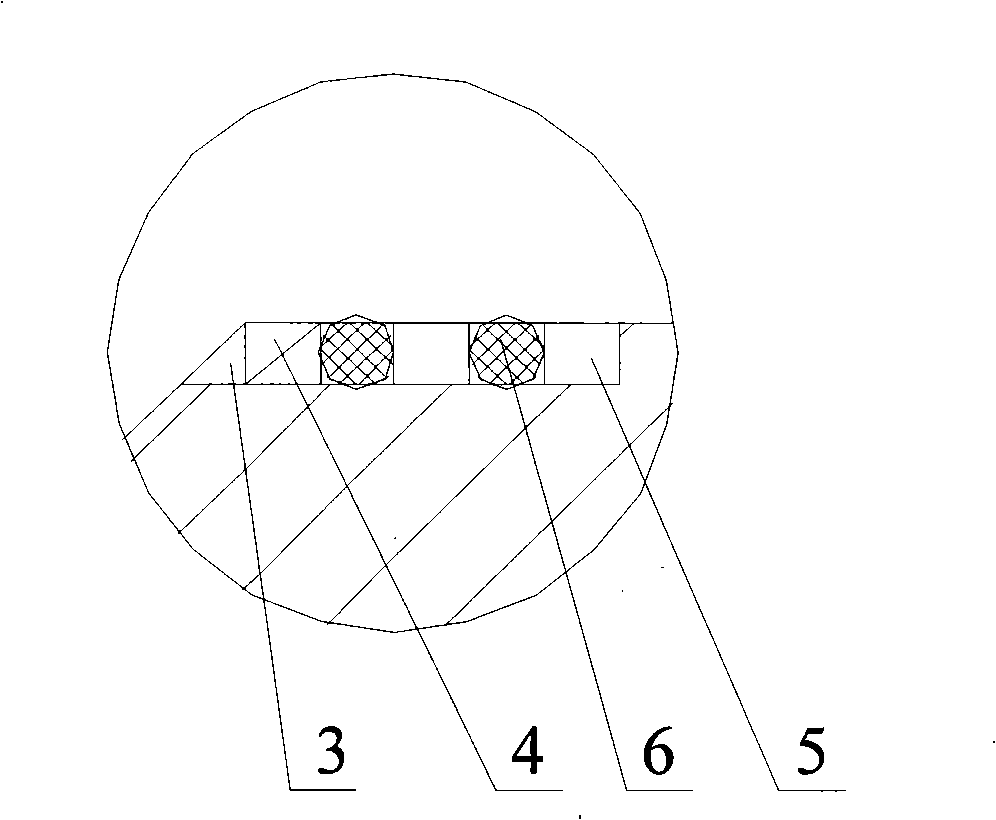

[0016] figure 1 It is a schematic diagram of the assembly of the sealing device of the present invention, figure 2 for figure 1 The enlarged schematic diagram of the structure of part A in the middle. The cylinder body 1 of the ultra-high pressure vessel is provided with a trapezoidal groove near the outlet. During assembly, the sealing device is pre-installed in the trapezoidal groove of the cylinder body 1 of the ultra-high pressure vessel; the plug 2 and the cylinder body 1 of the ultra-high pressure vessel are connected together by threads , the end of the plug 2 close to the inner side of the ultra-high pressure vessel cylinder 1 is an inclined plane, which matches the triangular gasket 3 of the sealing device to achieve a double seal; the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com