Method and system for checking SMT paster formula correctness

A correctness and programming technology, applied to measuring devices, instruments, etc., can solve problems such as delayed delivery, long time for new product introduction, low efficiency, etc., to achieve the effect of expanding production capacity, saving downtime and waiting time, and avoiding a lot of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The present invention aims at the large amount of work of online manual inspection of the first piece of SMT patch, and designs a machine that automatically completes the inspection work by a computer and has a large number of single-board components, which has a short inspection time and a high accuracy rate. The downtime and waiting time of the SMT process is saved, which is beneficial to the expansion of production capacity and the effect of improving efficiency. The invention will be described in detail below in conjunction with the diagrams.

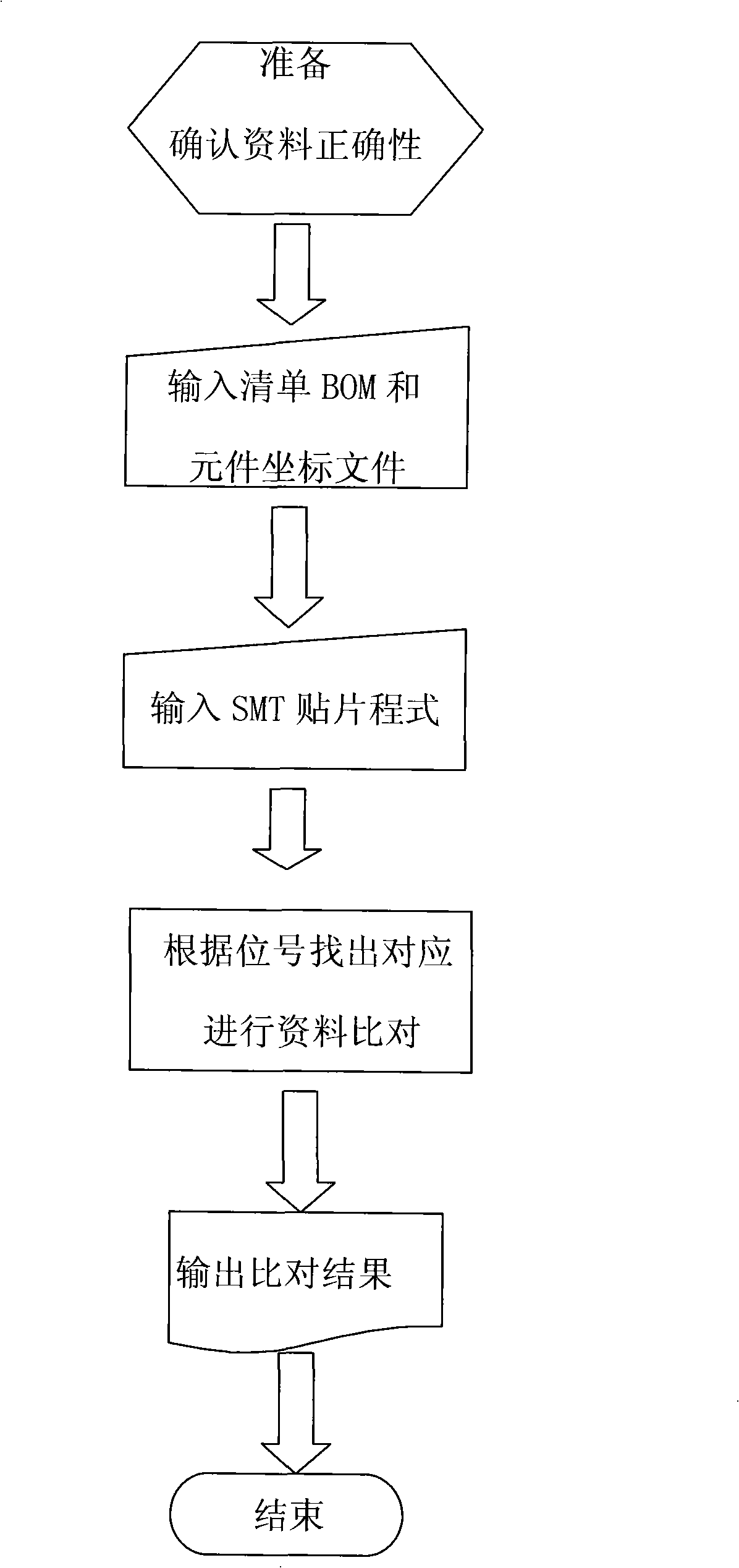

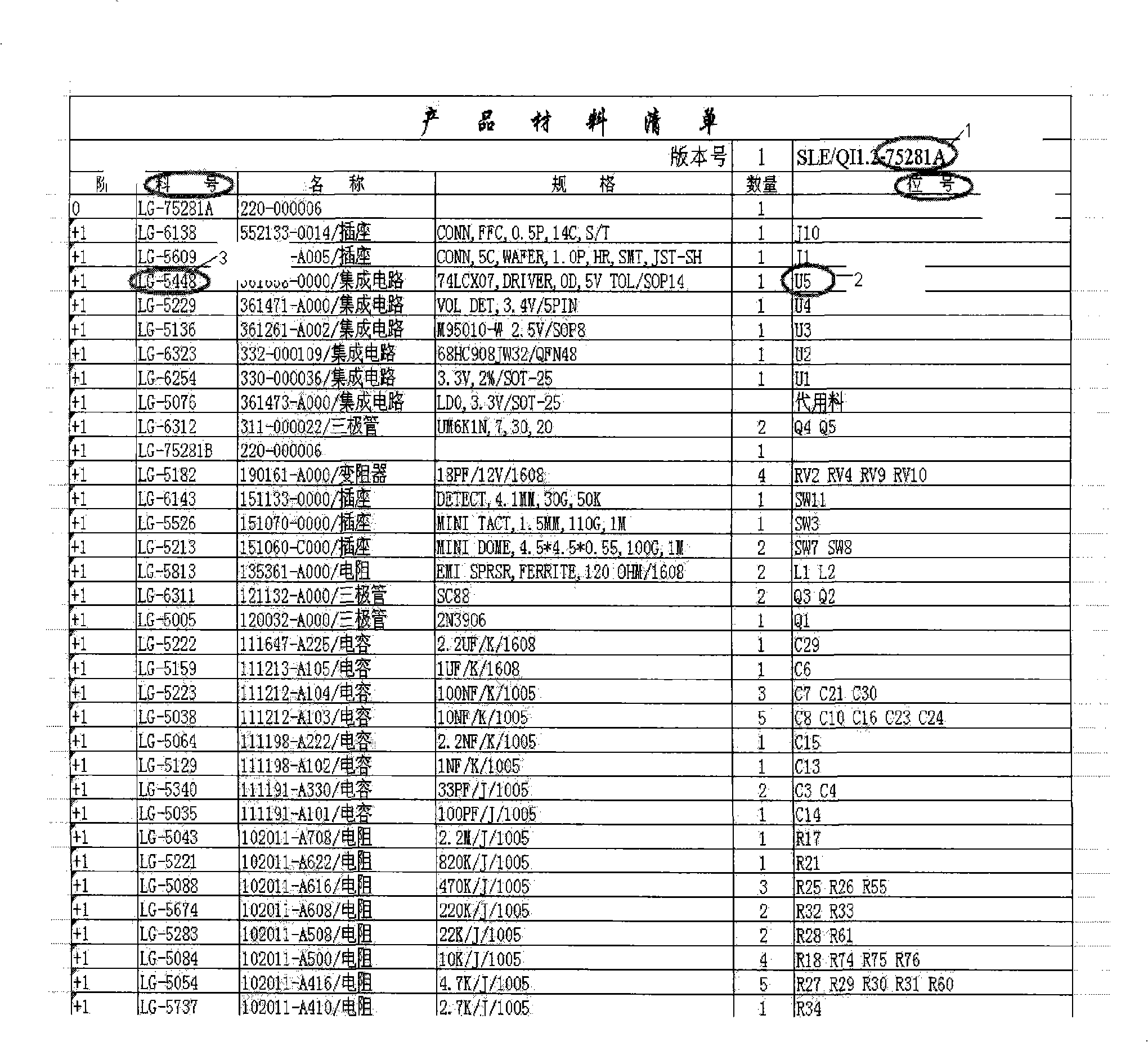

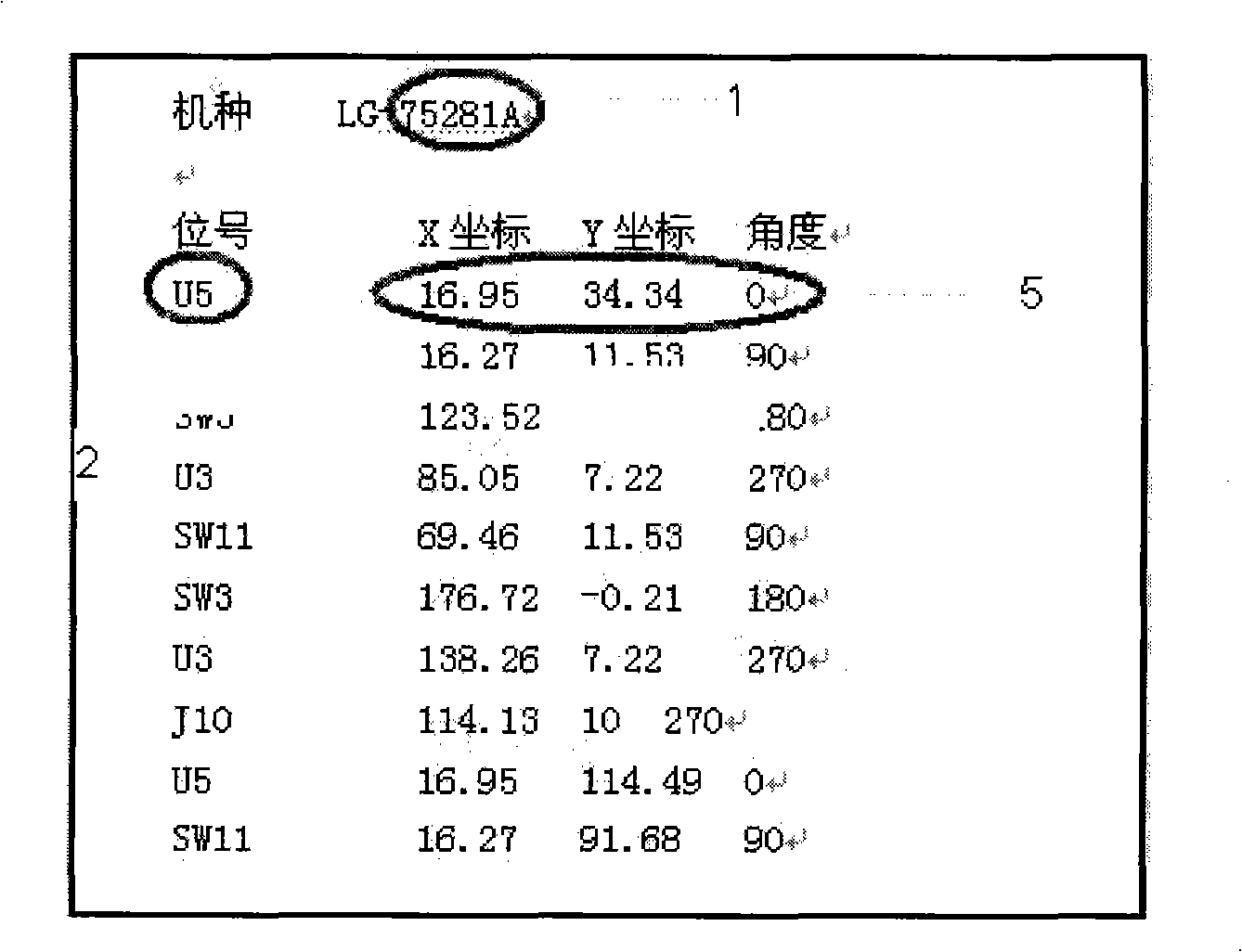

[0028] figure 1 Shown is the flow chart of the method for checking the correctness of the SMT placement program, by sorting out the relevant data on the coordinates and angles of the relevant components collected on the circuit board; the standard format of the list (BOM) has been distinguished The bottom surface and the top surface include the component material number, component specification, and component nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com