Veneer and processing method thereof

A processing method and veneer technology, which are applied in the direction of wood processing utensils, chemical instruments and methods, manufacturing tools, etc., to achieve the effect of enhancing the use value, saving wood resources, and facilitating selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

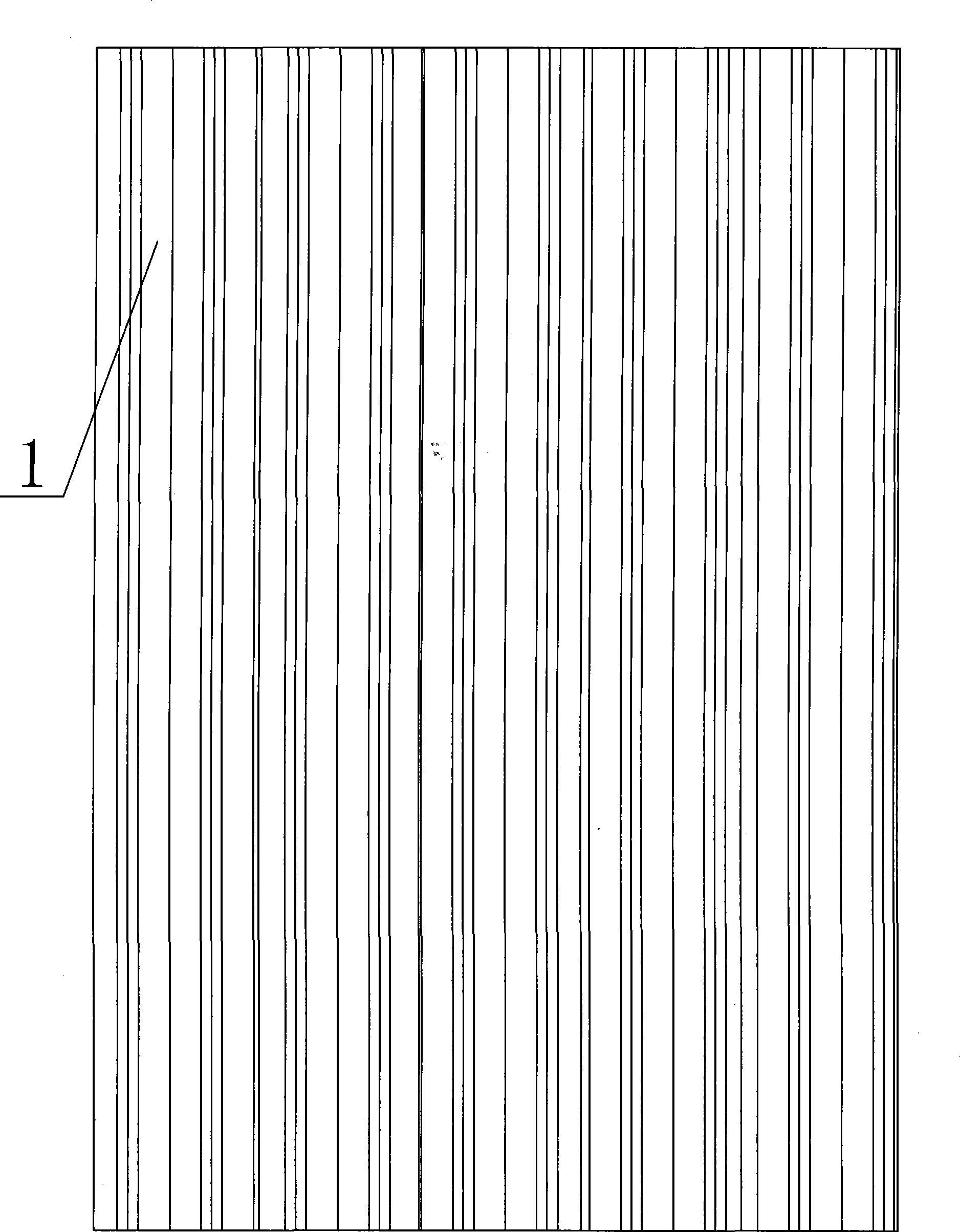

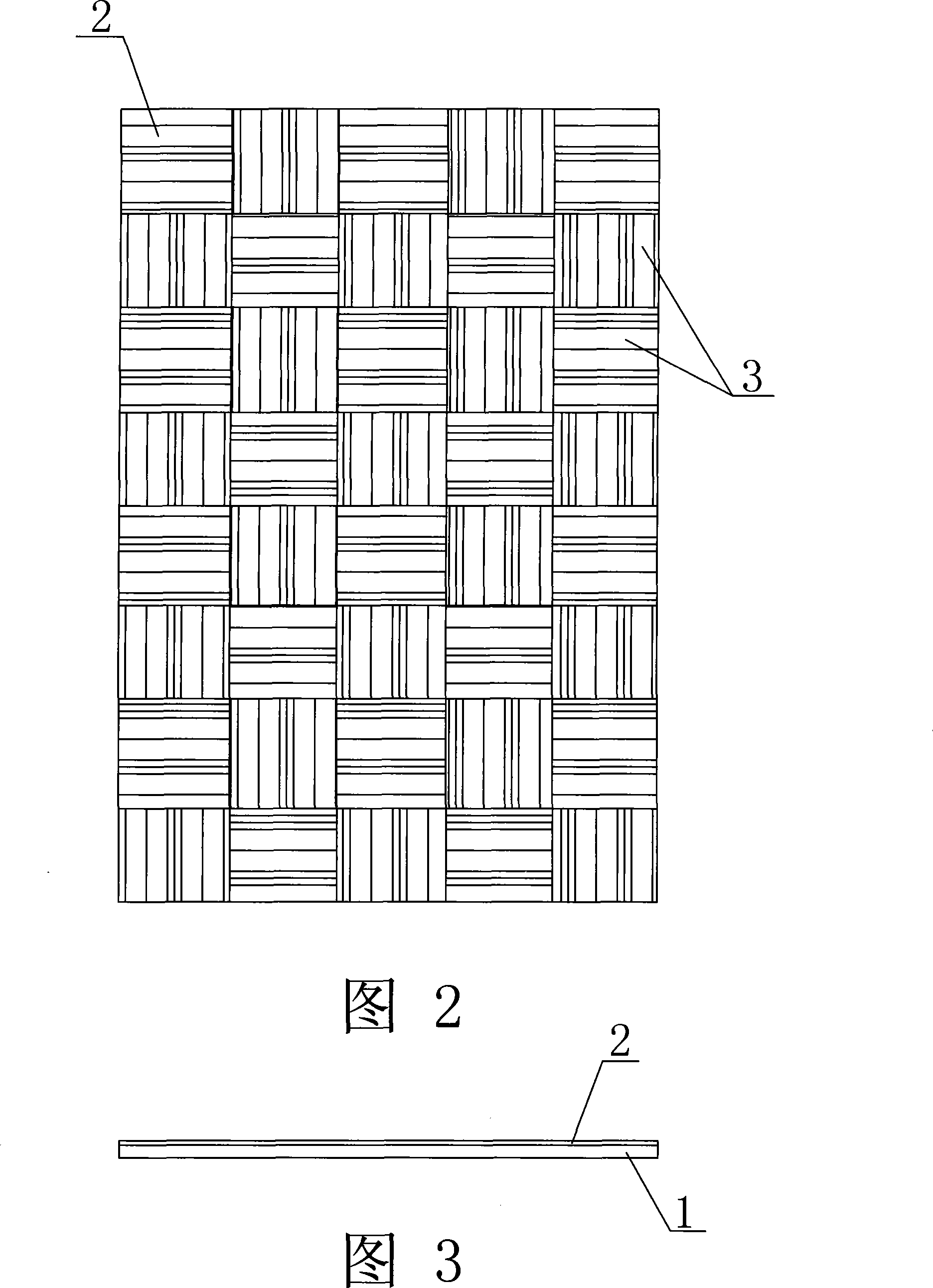

[0021] Embodiment 1: a kind of veneer of the present invention, as shown in Fig. 2, Fig. 3, comprises substrate 1, and substrate 1 is veneer, is bonded with one deck thickness on substrate 1 and is the veneer 2 of 0.1mm, so The veneer 2 described above is made up of several veneers 3 spliced in a criss-cross pattern with wood grain textures, that is, when placed, the wood grain textures on each veneer 3 are either parallel to the horizontal plane or perpendicular to the horizontal plane. The shape of veneer 3 is various, can all adopt square, also can all adopt rectangle, also can adopt square and rectangle interlaced stitching, the surface area of square veneer 3 is 144~169 square centimeters, the surface area of rectangular veneer 3 It is 288-388 square centimeters. The surface of the veneer in this embodiment is spliced with square veneers with an area of 144 square centimeters in a criss-cross pattern. After the consumer buys it, he can cut it out once and use it...

Embodiment 2

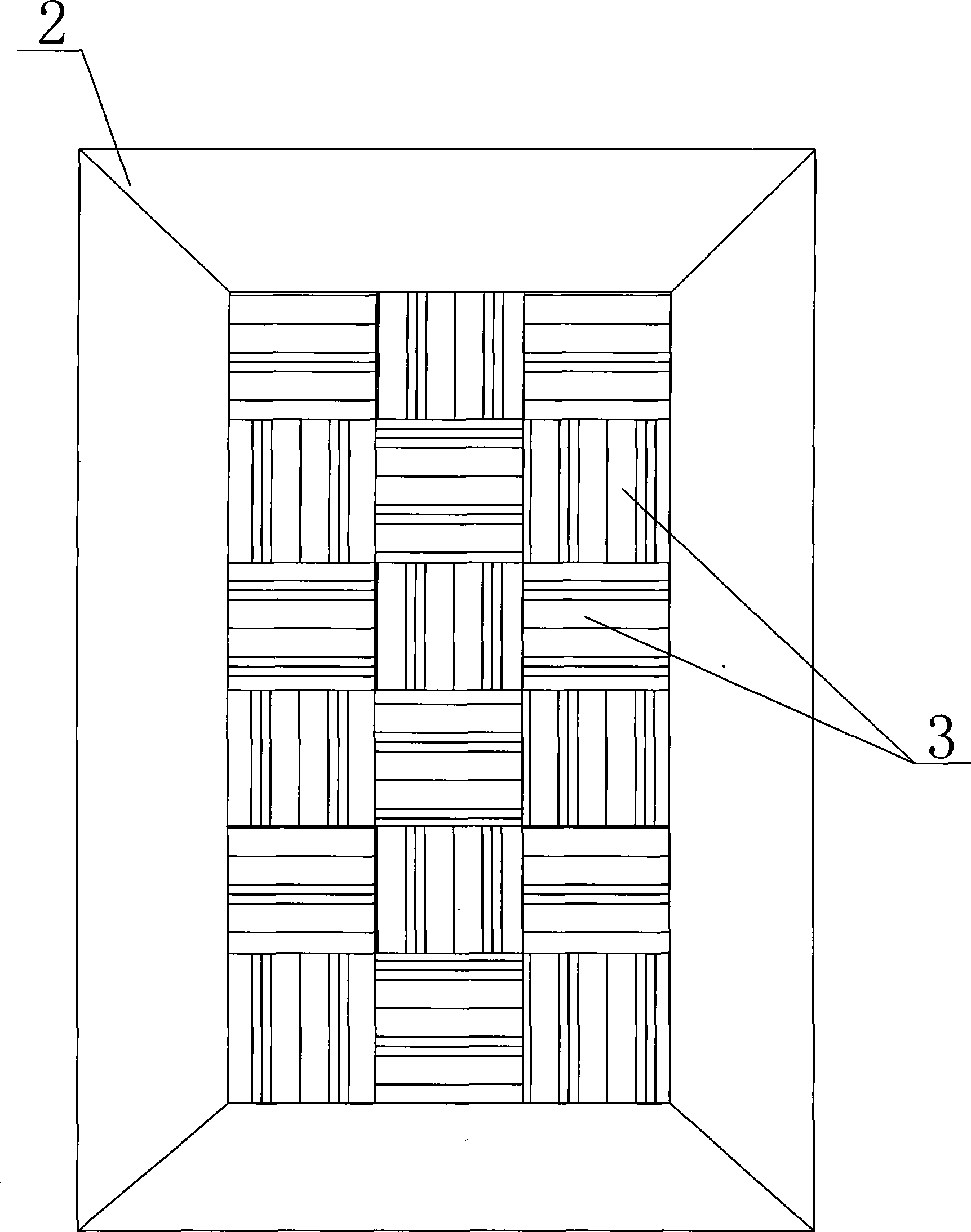

[0023] Embodiment 2: as Figure 4 As shown, in this embodiment, four strips of thin veneers 2 are first bonded around the upper surface of the substrate, two adjacent veneers are closely spliced at the adjacent joints, and then four strips of thin veneers are bonded together. In the rectangular area surrounded by the veneer 2, several pieces of rectangular veneers 3 with wood grain textures criss-crossed and spliced are bonded. In this way, a whole veneer with a woven pattern is formed, and consumers do not need to cut it, and it can be used as a whole veneer for decoration. Other technical schemes are identical with embodiment 1.

Embodiment 3

[0024] Embodiment 3: as Figure 5 As shown, several pieces of rectangular veneer 3 can also be spliced obliquely with wood grain texture, that is, when cutting or placing splicing, the wood grain texture on each veneer 3 is inclined at a certain angle relative to the horizontal plane , the angle is an acute angle. In this embodiment, the wood grain texture on each piece of veneer 3 is inclined at an angle of 45 degrees relative to the horizontal plane. Other technical solutions are the same as in Embodiment 1. The panel pattern is more beautiful and more favored by consumers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com