Die-cutting mark press (or thermoprinting machine) with paper holding and locating at the feed portion and one time paper-push-paper movement

A technology of die-cutting and indentation, applied in the direction of machining/deformation, etc., can solve the problems of complex and huge structure, and achieve the effect of ensuring continuity, simple structure and improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

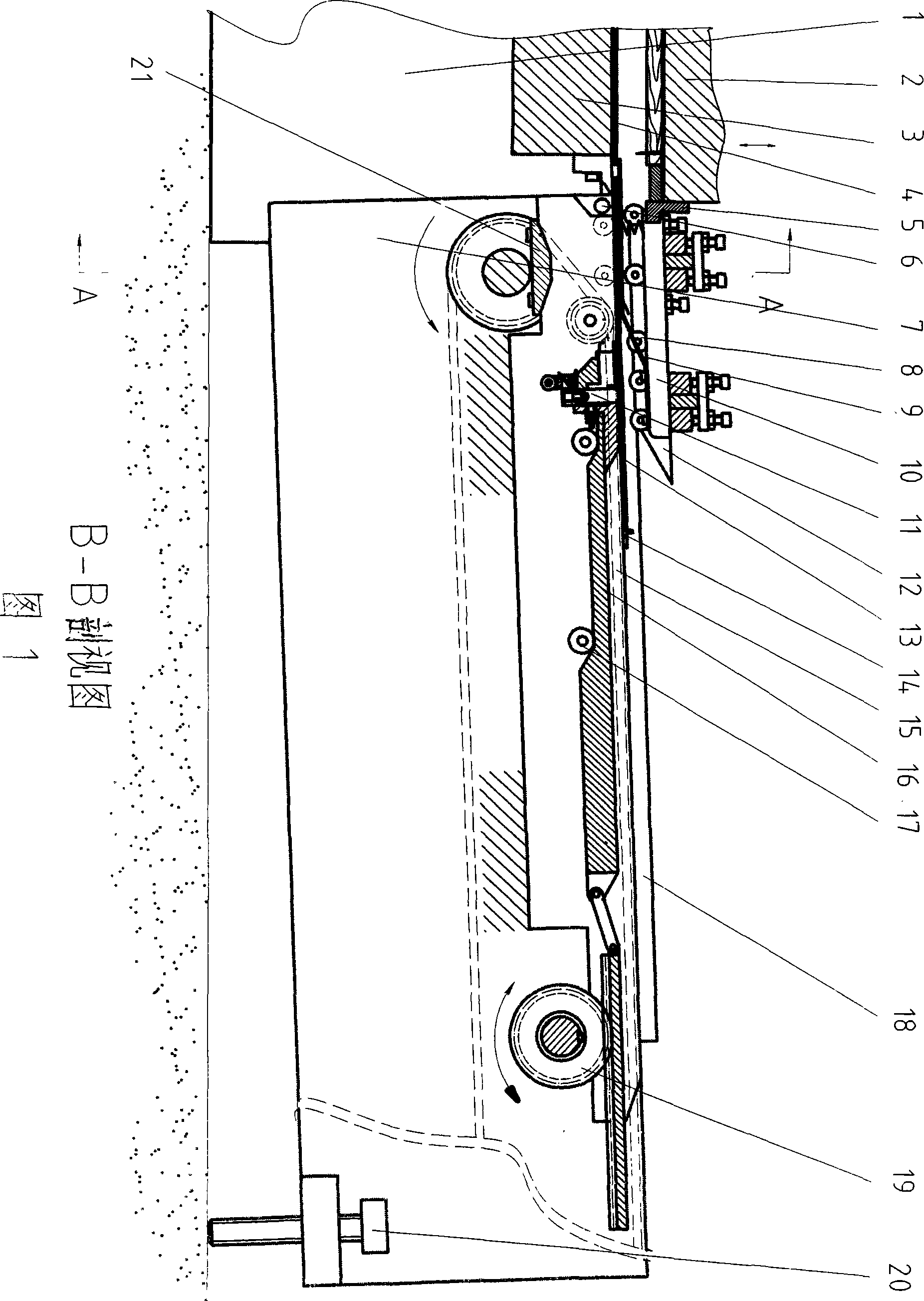

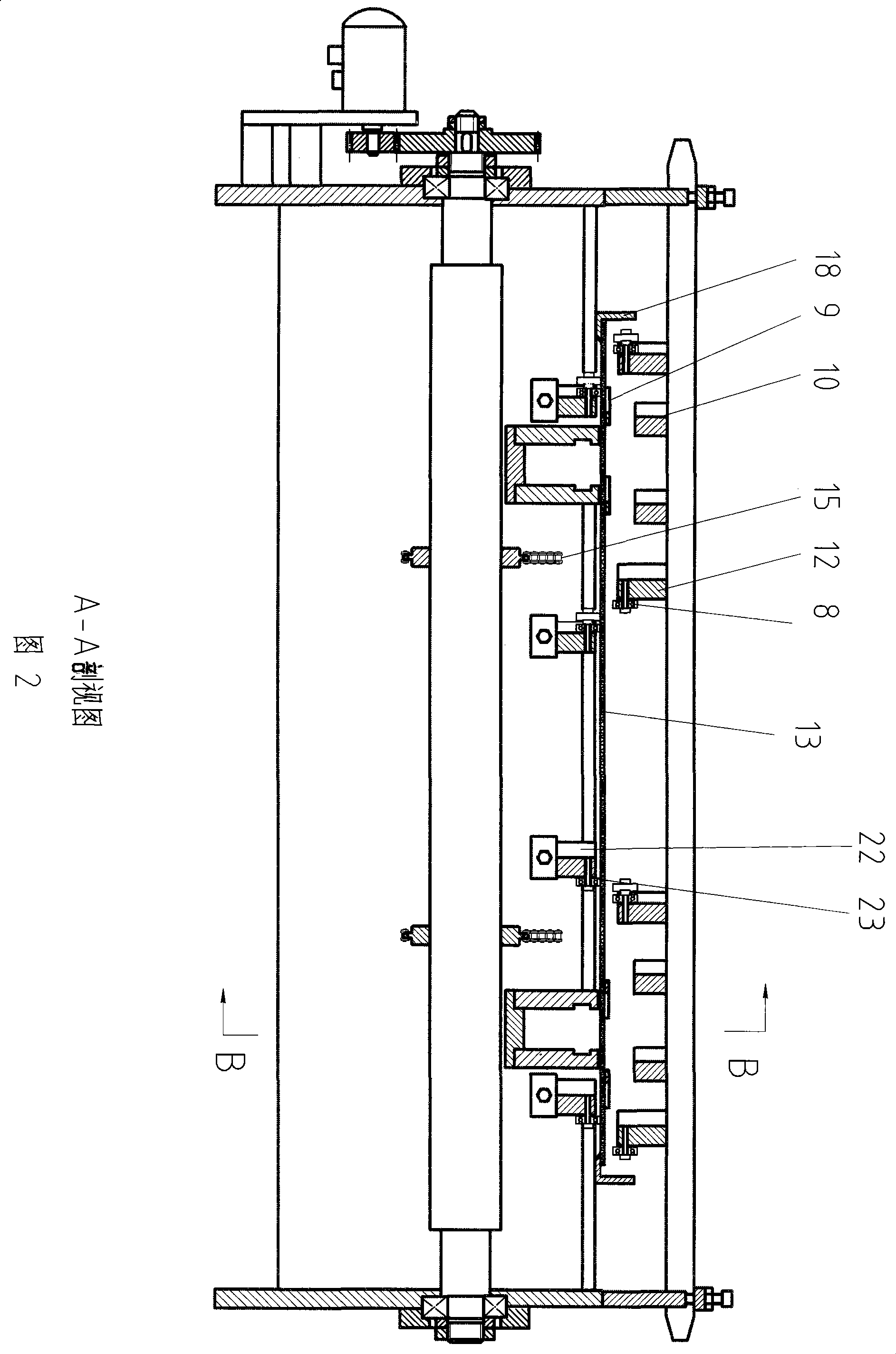

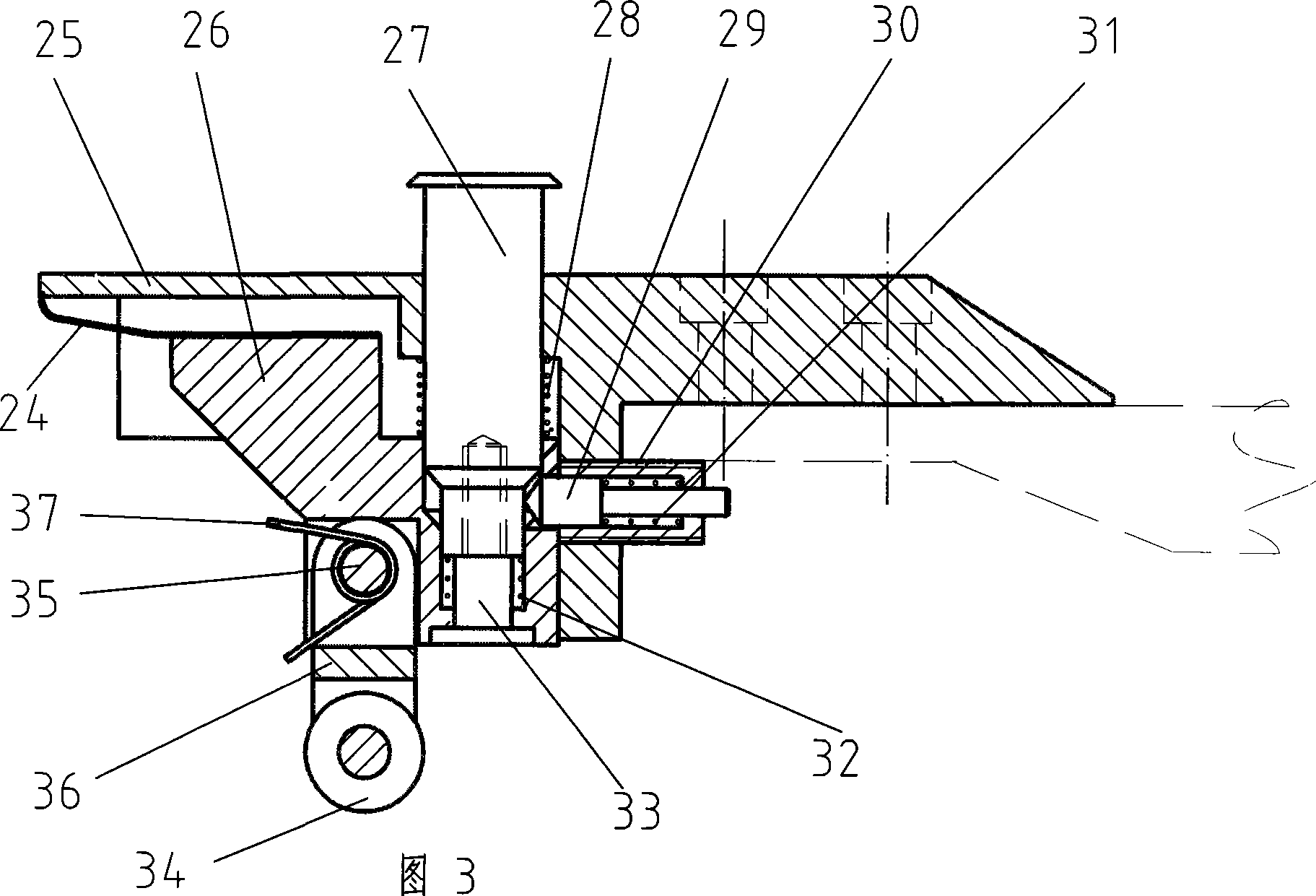

[0025] Fig. 1 is the overall structural diagram of the paper continuation and positioning system of the present invention: the machine has a host wallboard 1, an upper stamping pallet 2 that moves up and down, a pressing iron 5 is installed on the stamping pallet, and there is a fixed mounting The lower pallet 3 for embossing has a cardboard pallet 7 and foot screws 20 installed on it, side positioning gauges 18 and clamping inclined irons 21, and a cardboard conveying device 15, which is mainly composed of a paper pusher. 14, chain pulley 40 (seeing Fig. 6), sprocket wheel and chain transmission mechanism are made up of, and paper pusher 14 is connected on the chain with hinge; 17 and rack and pinion transmission mechanism are formed; The paper-out stick 39 (seeing Fig. 5) of non-stop motion is installed on the trailing edge of pallet 3 under embossing.

[0026] Realization of frontier positioning:

[0027] Cardboard positioning adopts two paper-push positioning gauges 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com