Production process of lithium alcoholate

A production process, lithium alkoxide technology, applied in metal alkoxide preparation, organic chemistry, etc., can solve problems such as easy to catch fire, difficult to achieve industrialized production, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

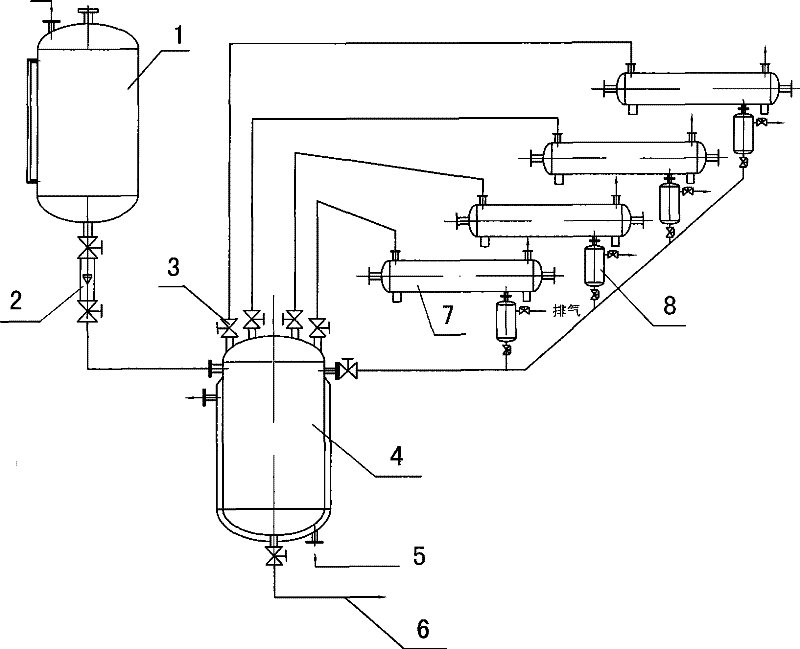

[0018] figure 1 It is a schematic diagram of the structure of the reaction device, which is intended to facilitate the description of the process of the present invention. Add 15kg lithium metal and 1000kg ethanol measured in the 2000L liter reaction tank. Before starting the dropwise addition, first turn on the ice water to cool down, the temperature drops to -20~-26°C, start to drop the measured alcohol (usually within 7 hours), and start dropping slowly through the metering tank , when it is added dropwise to 200L, close the ice water cooling valve, so that the temperature begins to rise slowly, and the temperature is controlled at 60-80 degrees (preferably 65-70 degrees C). During the reaction process, all 4 exhaust valves must be opened. The cooling valves of the stage condensers are fully opened. The gas components are condensed through the condenser, and the alcohol in it is condensed and refluxed through the collection tank to the reaction tank. After normal operati...

Embodiment 2

[0021] Different from Example 1, 15kg lithium metal was added to the reaction tank, and 900kg methanol was added to the alcohol metering tank. The mass content of lithium methoxide in the liquid lithium methoxide is 29%.

[0022] In the rake dryer, the vacuum degree is controlled to be 0.01-0.1Mpa, the temperature is 120°C, and the drying time is 14 hours. Lithium methoxide was obtained as a white crystalline powder solid. After testing, the mass content of lithium methoxide is 98.9%, the free alcohol is less than 0.5%, and the moisture content is zero.

Embodiment 3

[0024] Different from Example 1, 15kg lithium metal was added into the reaction tank, and 950kg n-butanol was added into the alcohol metering tank. The mass content of lithium n-butoxide in the liquid lithium n-butoxide is 28.5%.

[0025] In the rake dryer, the vacuum degree is controlled to be 0.01-0.1Mpa, the temperature is 100°C, and the drying time is 12 hours. Lithium n-butoxide was obtained as a white crystalline powder solid. After testing, the mass content of lithium n-butoxide is 98.8%, the free alcohol is less than 0.5%, and the moisture content is zero.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com