Disc mill and method for controlling action element action in beating process thereof

A control method and disc refiner technology, applied in pulp beating/refining method, electrical program control, digital control, etc., can solve the problems of pulp conveying device failure, grinding disc rupture, low liquid level in the pulp pool, etc., to prevent The effect of friction collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

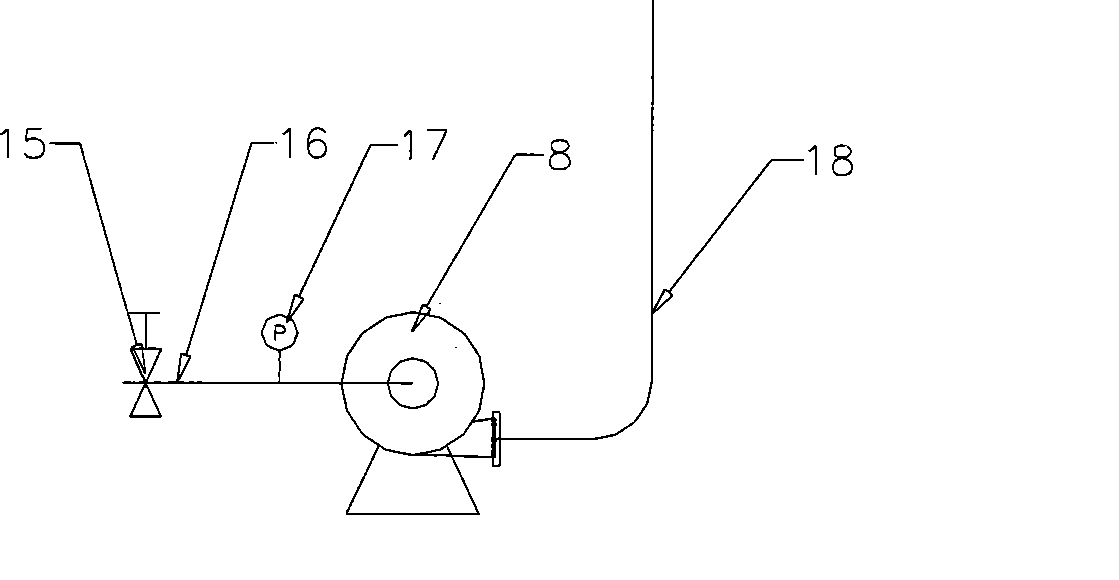

[0033] In this embodiment, the installation position of the pressure sensor 17 is as follows image 3 As shown, the pressure sensor is installed on the slurry feeding pipeline 16.

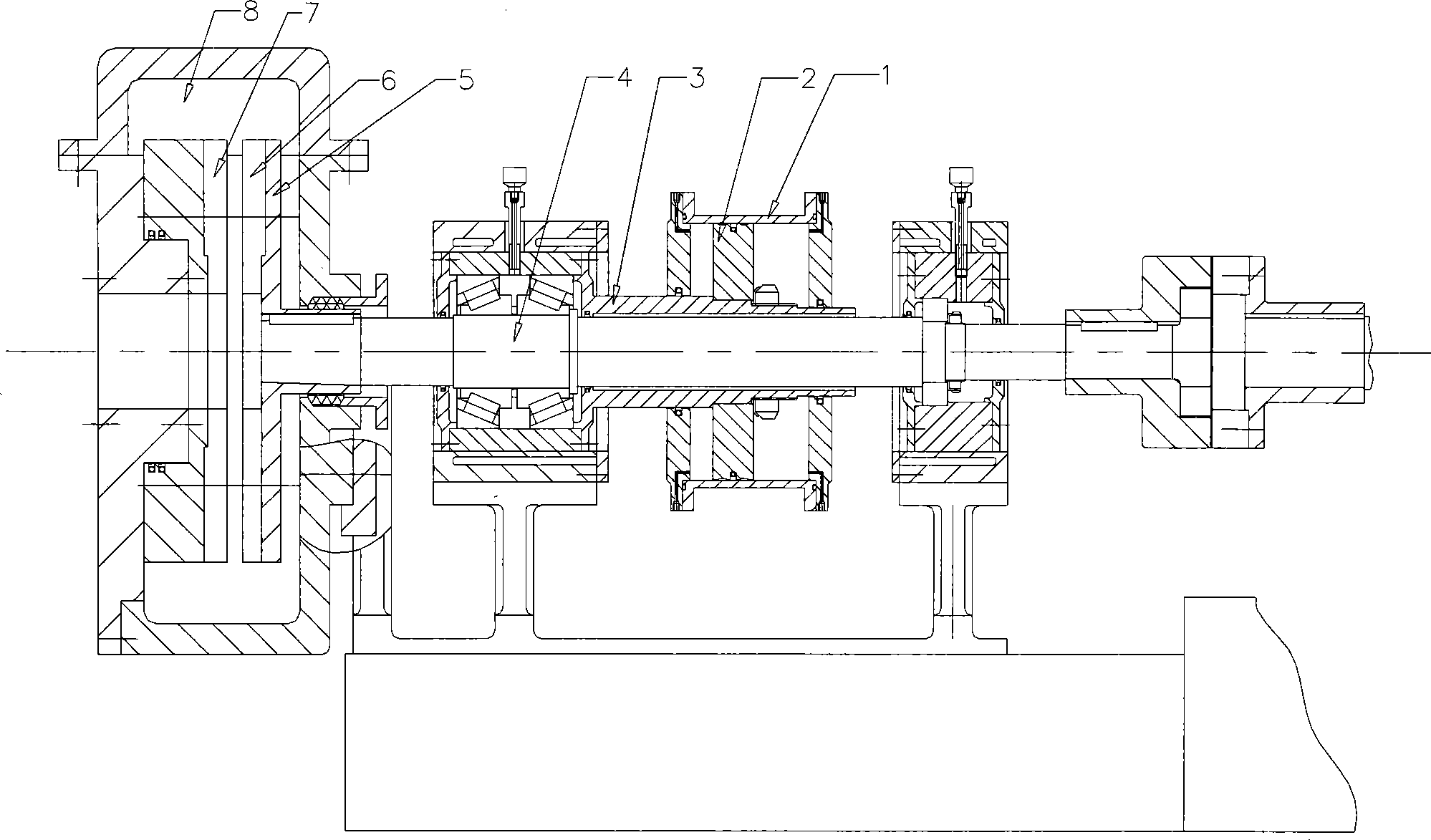

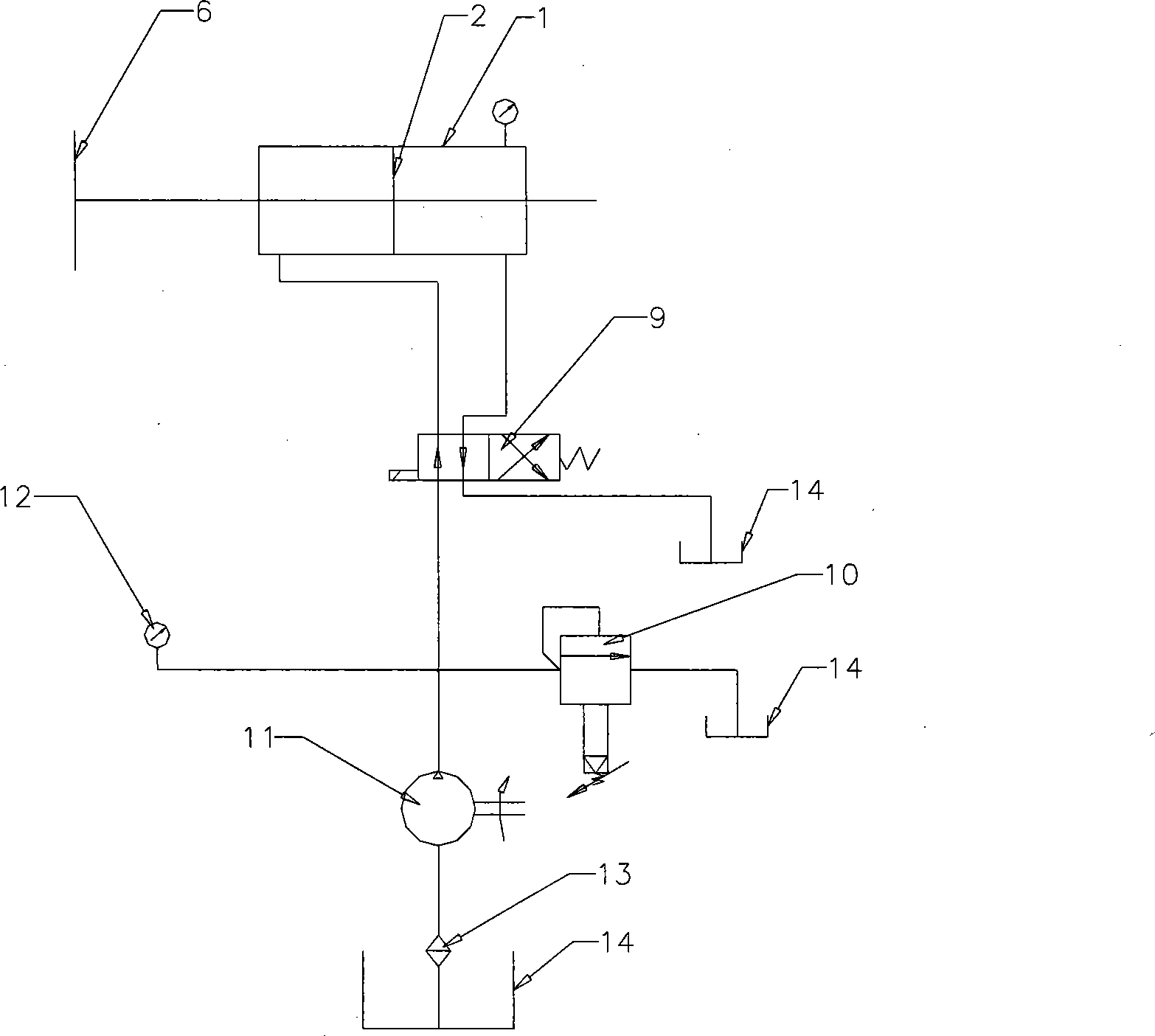

[0034] (1) When the pulp tank before the mill is full of pulp, start the beating system for beating. Connect the power supply of the disc grinder control device, start the disc grinder hydraulic control system, and then start the main motor to make the disc grinder motorized disc 6 rotate with the shaft 4. The pressure oil of the hydraulic control system enters the left side of the oil cylinder 1 through the oil tank 14, the oil filter 13, the oil pump 11, and the electromagnetic reversing valve 9. The pressure oil pushes the piston 2 to move to the right, and pushes the sleeve 3 to drive the shaft 4 to move to the right. Make the movable millstone seat 5 and the movable millstone 6 move to the right, the movable millstone 6 leaves the fixed millstone 7, is in the state of withdrawing the knife, a...

Embodiment 2

[0040] Embodiment 2 has the same steps as Embodiment 1, the difference is that the installation position of the pressure sensor 17 is as follows: Figure 4 As shown, the pressure sensor 17 is installed on the slurry outlet pipeline 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com