Multi-direction multi-shaft stirring concrete earth pile machine

A technology of cement-soil pile driver and fuselage, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve the problems of large drill bit, inconvenient maintenance, and large drill bit resistance, so as to improve the working environment and stability , not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

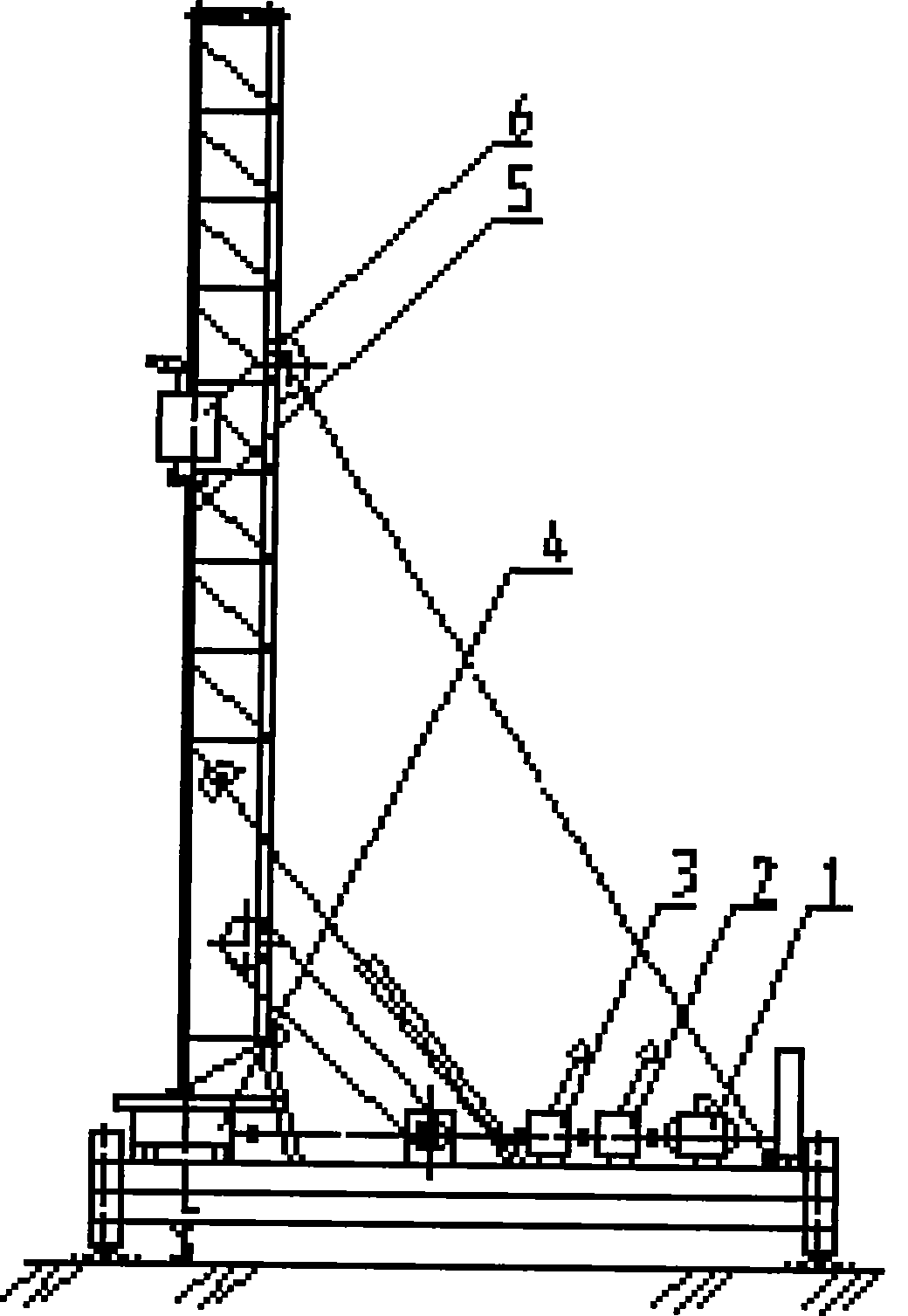

[0026] Explanation of marks in Fig. 1, electric motor 1, gearbox 2, forward and reverse case 3, rotary table 4, outer drill pipe 5, transmission case 6.

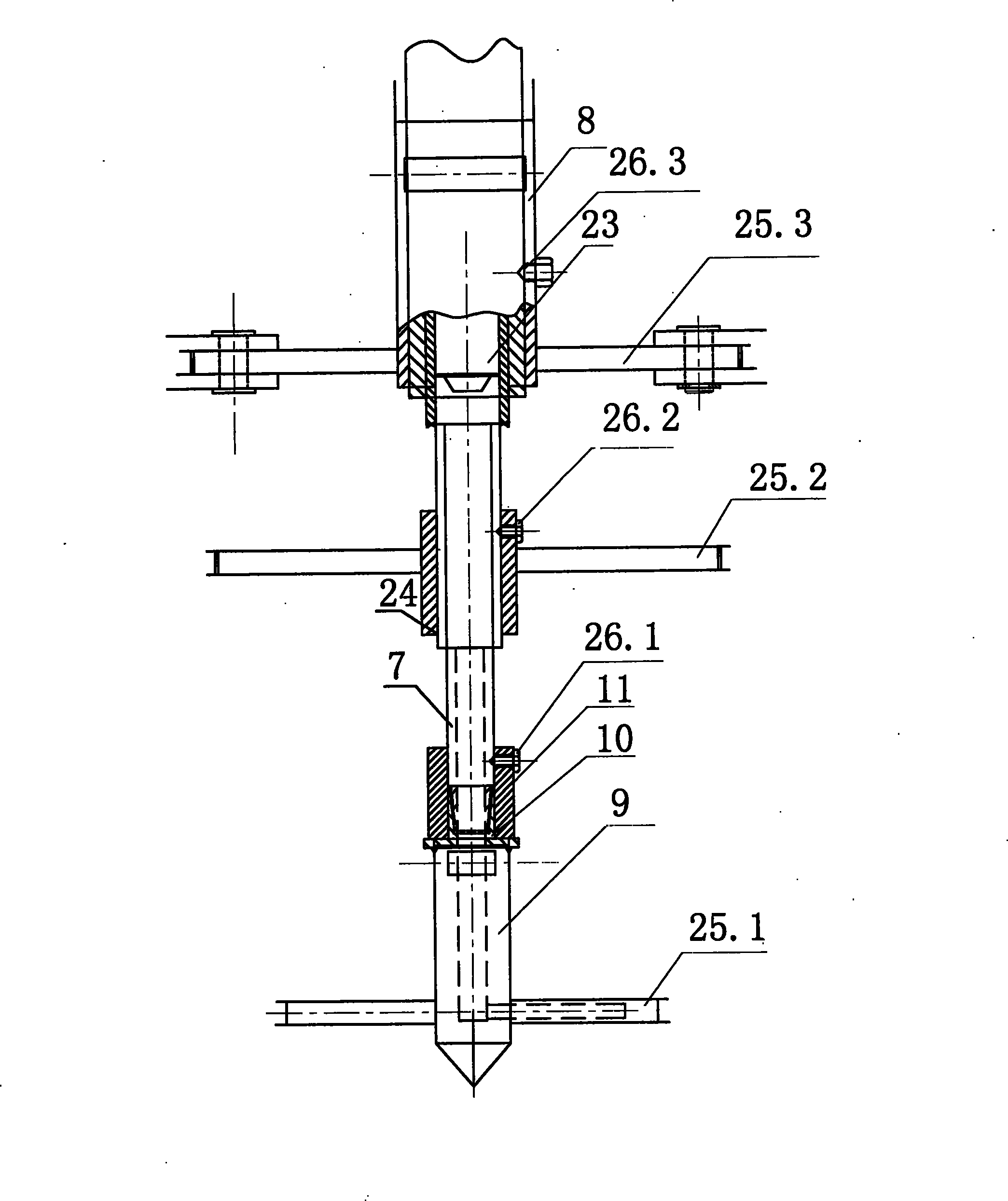

[0027] Explanation of mark among Fig. 2, inner drilling rod 7, outer stirring drill bit 8, inner stirring drill bit 9, union 10, small square cover 11.

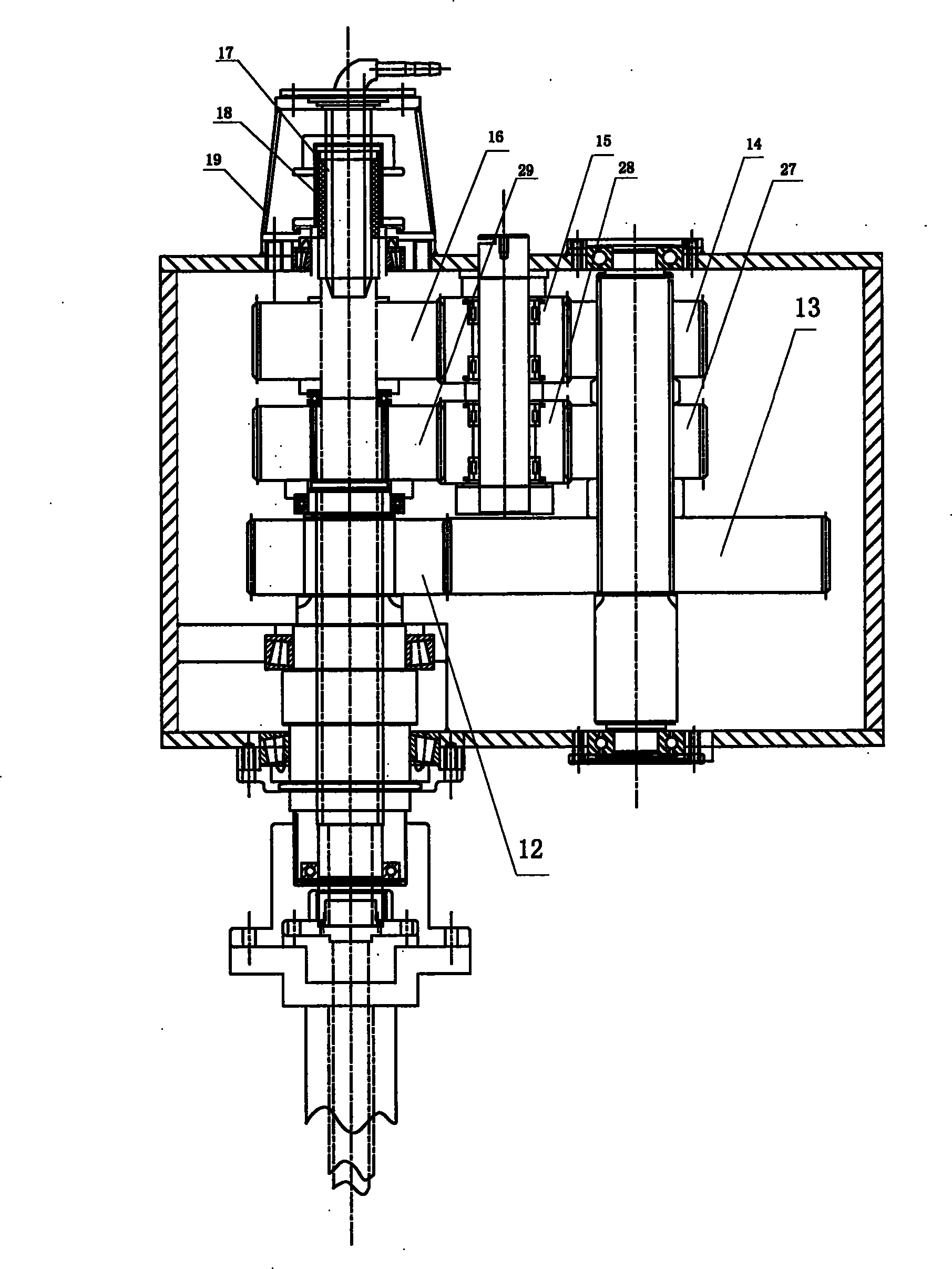

[0028] Explanation of marks in Fig. 3, driving wheel 12, driven wheel 13, coaxial gear 14, reversing wheel 15, inner drill rod gear 16, core pipe 17, skeleton oil seal 18, double-layer flange 19.

[0029] In the illustration of the mark in Fig. 4, the speed regulating motor 20, the worm gear reducer 21, and the chain 22.

[0030] Explanation of marking among Fig. 5, middle drilling rod 23, middle stirring drill bit 24, blade 25.1, 25.2, 25.3, screw 26.1, 26.2, 26.3.

[0031] 6, coaxial gear 27, reversing wheel 28, middle drill rod gear 29, core pipe 30, skeleton oil seal 31, double-layer flange 32.

[0032] Referring to Fig. 1, Fig. 2 and Fig. 3, the multi-directional and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com