Method for eliminating pit buoyancy and pit structure

A buoyancy and pit technology, which is applied to the method and pit structure, eliminates the field of pit buoyancy, can solve the problems of material waste and large amount of materials, and achieves the effect of reducing material consumption, reducing construction difficulty, and realizing controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

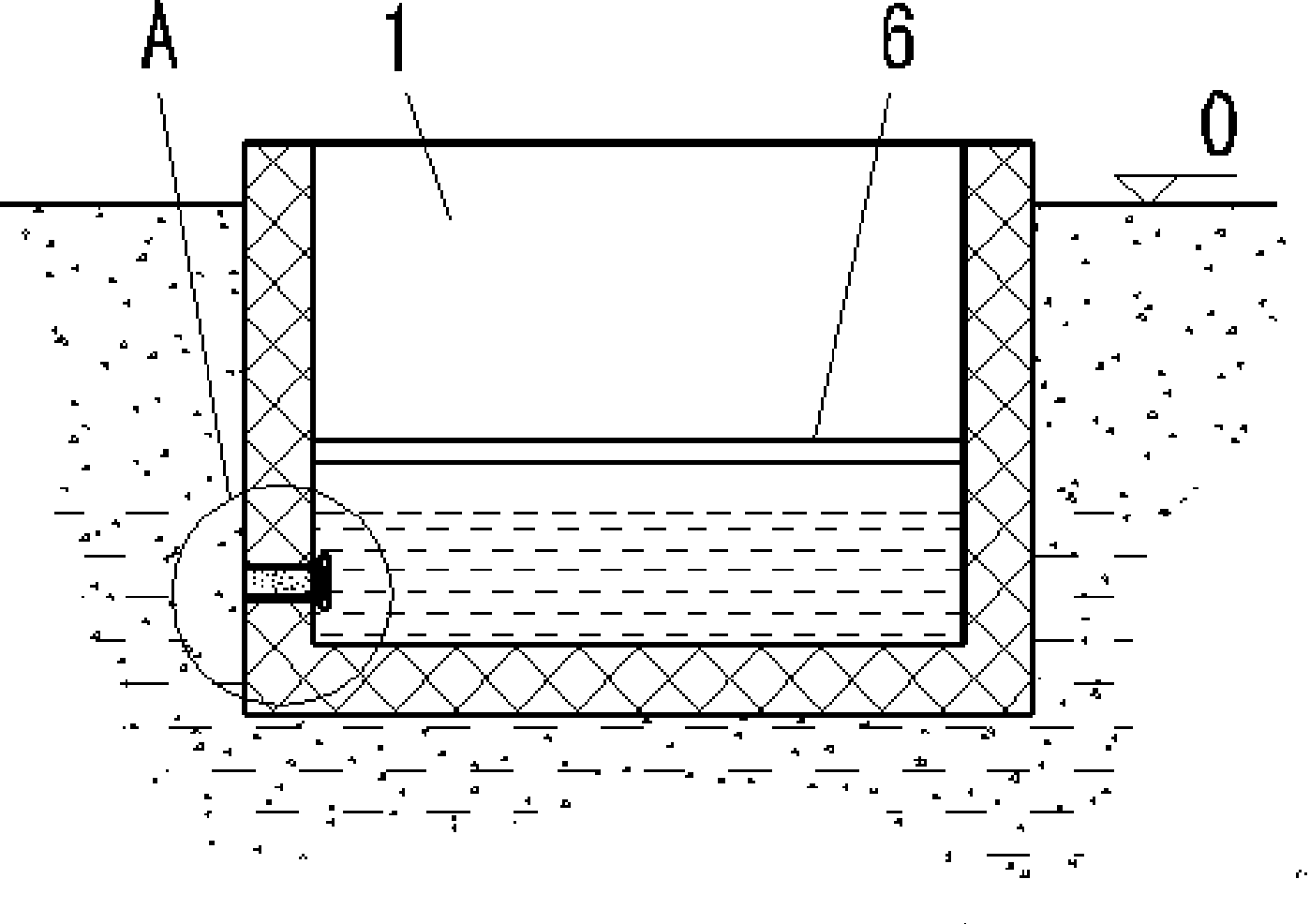

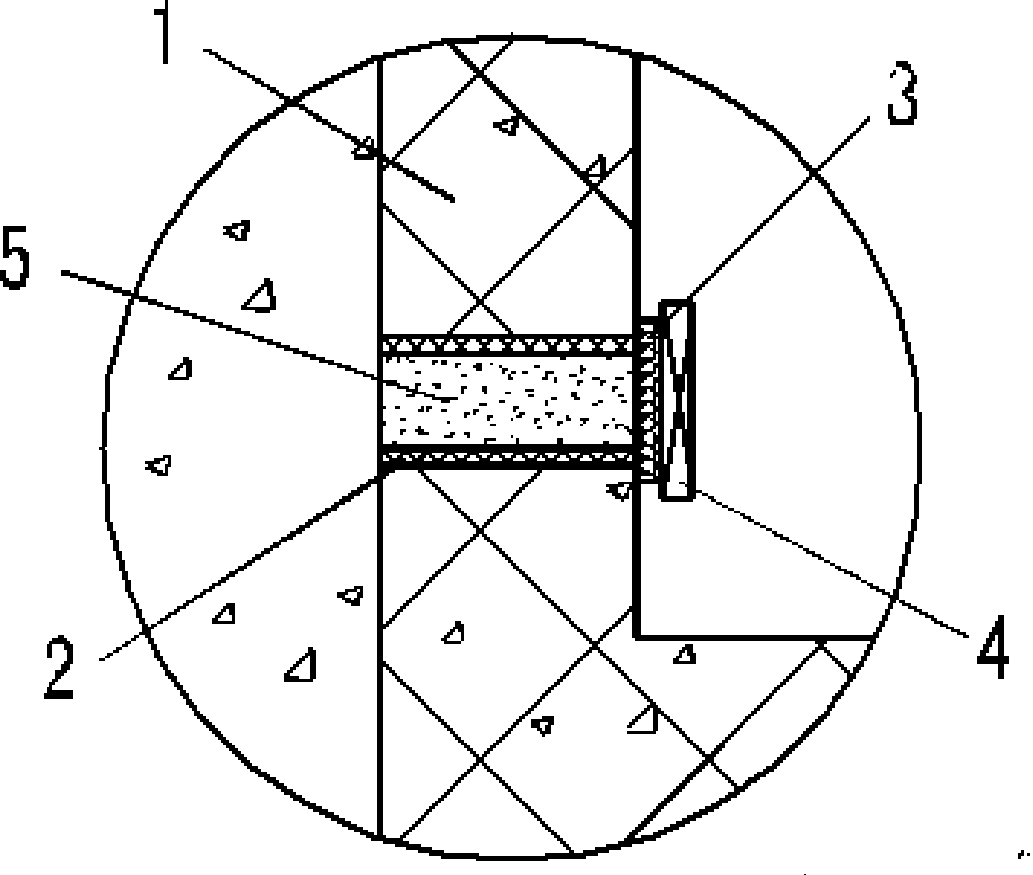

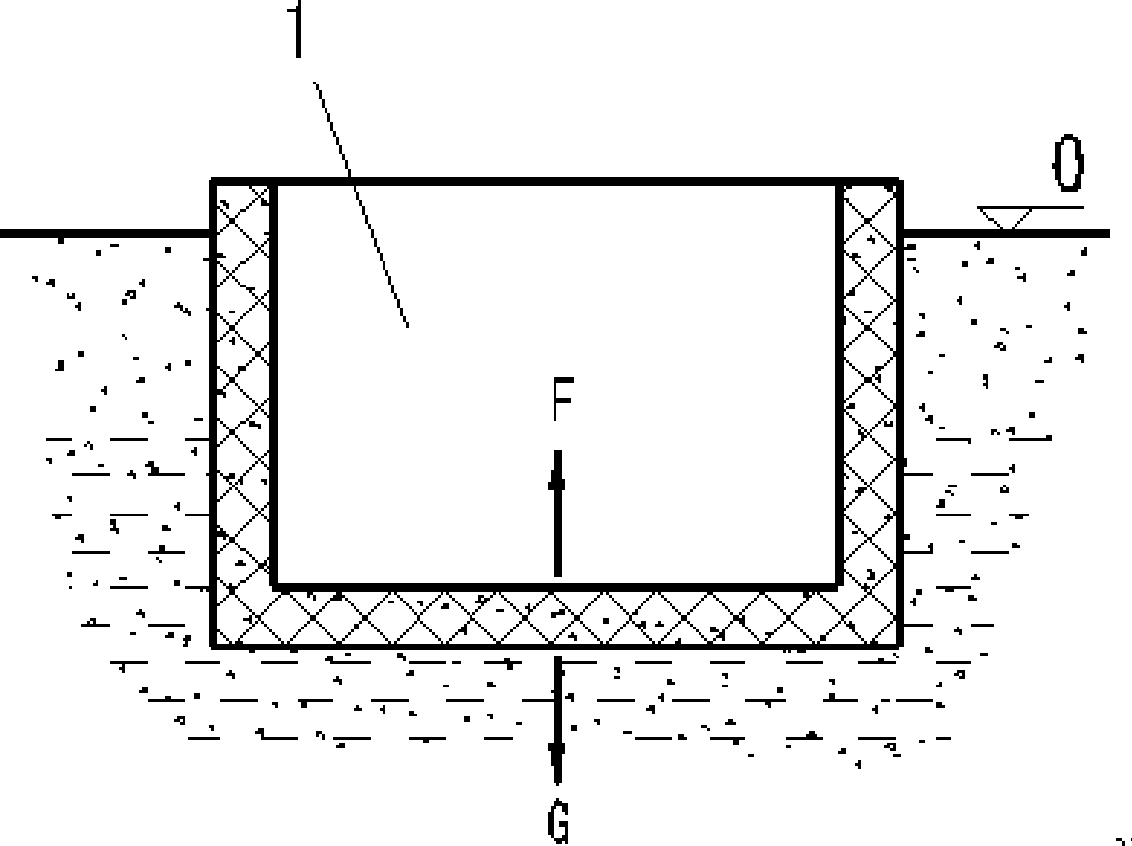

[0018] Example. The method for eliminating the buoyancy of the pit of the present invention and the pit structure such as figure 1 and figure 2 shown. The method is to open an overflow hole on the ground pit, a filter screen is arranged at the opening of the overflow hole, and a filter layer is arranged in the hole of the overflow hole to prevent silt from entering the pit. When the groundwater level exceeds the overflow hole, the groundwater overflows into the pit, which increases the self-weight of the pit to balance the buoyancy brought by the rise of the groundwater level. The orifice of the overflow hole is provided with a water stop valve to artificially control the water level in the pit. There is a working platform in the pit above the overflow hole, and eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com