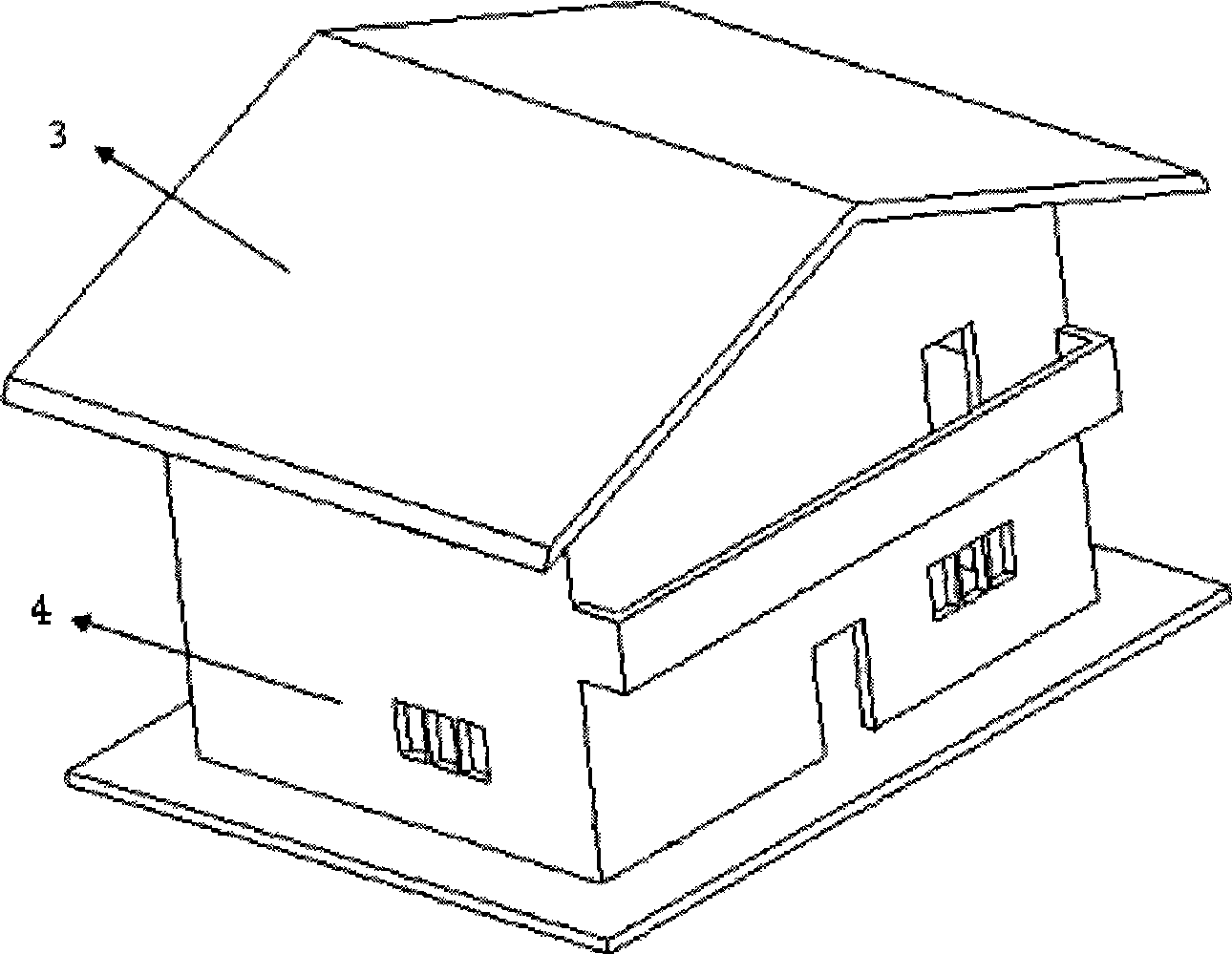

Gypsum reinforced concrete construction system

A technology of reinforced concrete and gypsum, which is applied to buildings, building components, building structures, etc., can solve the problems of high cost, high labor intensity, poor earthquake resistance, etc., and achieve the effects of low cost, fast construction and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

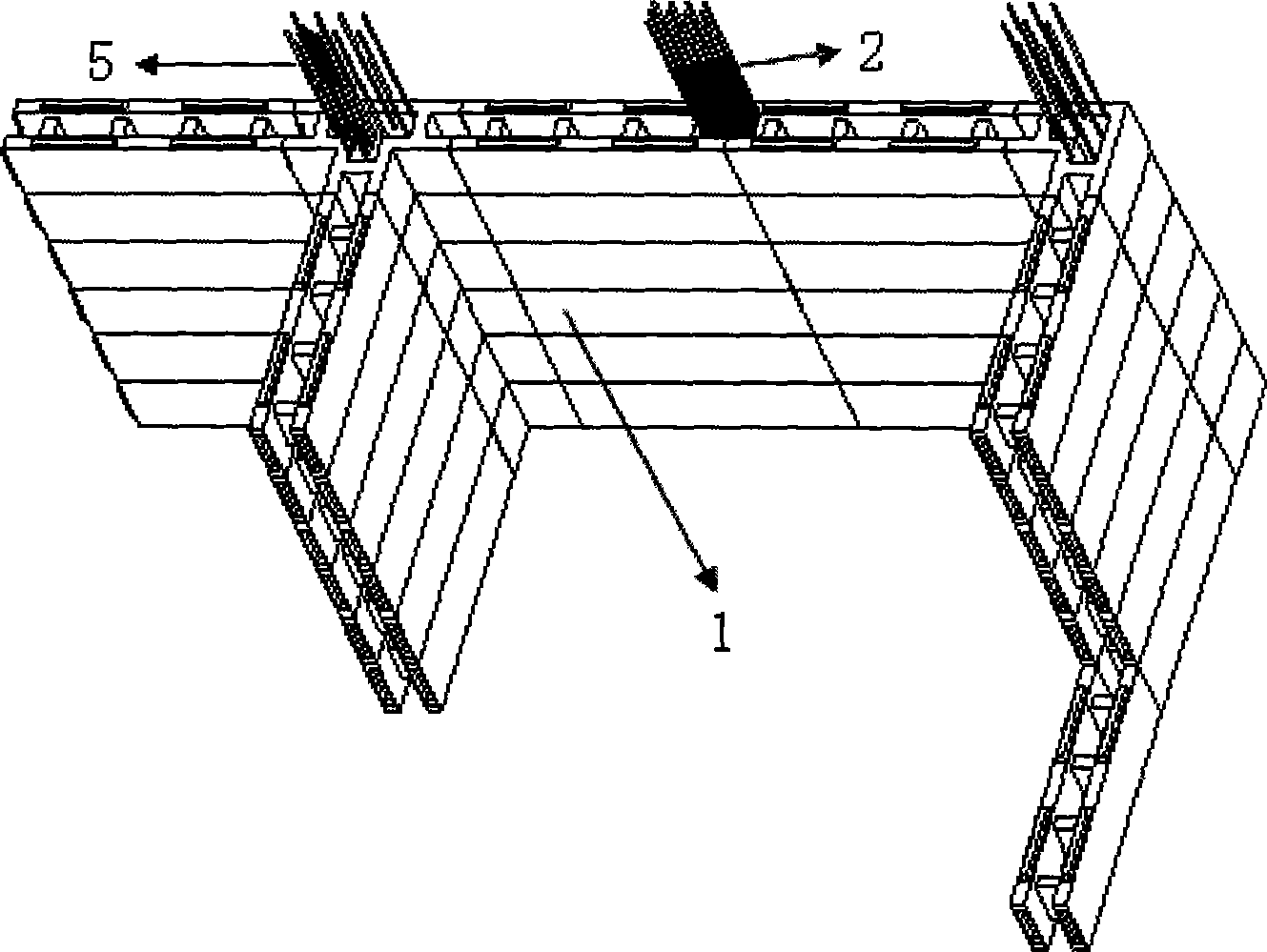

[0023] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

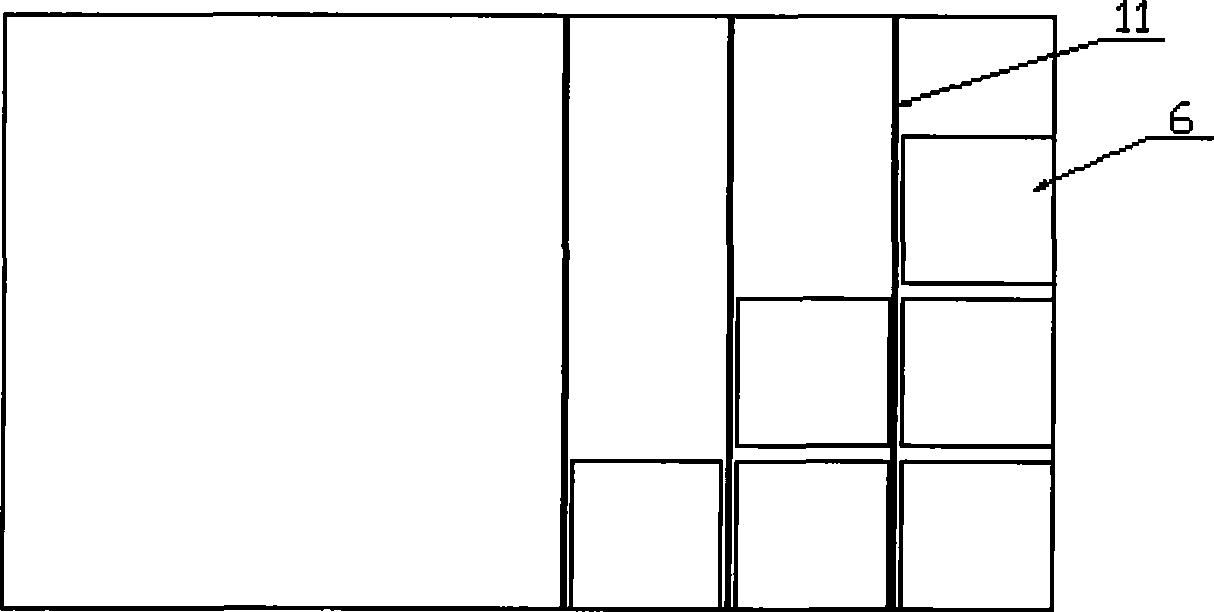

[0024] The invention is different from the frame light board building system and the brick-concrete structure building system, and is a new self-contained gypsum plus reinforced concrete building system. First of all, clean up the ground level, build the wall foundation and bottom ring reinforced concrete according to the design; build the gypsum wall 1 with hollow composite blocks 7 (reserve doors, windows and pre-buried pipelines). The ordinary hollow block 8 in the hollow composite block 7 is basically a rectangular hollow module (900mm×300mm, fully conforming to the building modulus of 3, 6, and 9, with a thickness of more than 200mm), and the frame thickness is more than 20mm. The tenons are closely connected with each other and cannot be misplaced; the thickness of the inner space of the block is more than 150mm, which can meet the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com