Platform for manufacturing liquid crystal display device and method for examining exogenous impurity on platform

A technology for liquid crystal display components and platforms, applied in manufacturing tools, workbenches, optics, etc., to solve problems such as sticking, wasting man-hours and manpower, and scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]A preferred embodiment is proposed below as an illustration of the present invention; however, the alignment film manufacturing machine proposed in the embodiment is only for illustration and does not limit the protection scope of the present invention. Furthermore, the illustrations in the embodiments also omit unnecessary elements to clearly show the technical characteristics of the present invention.

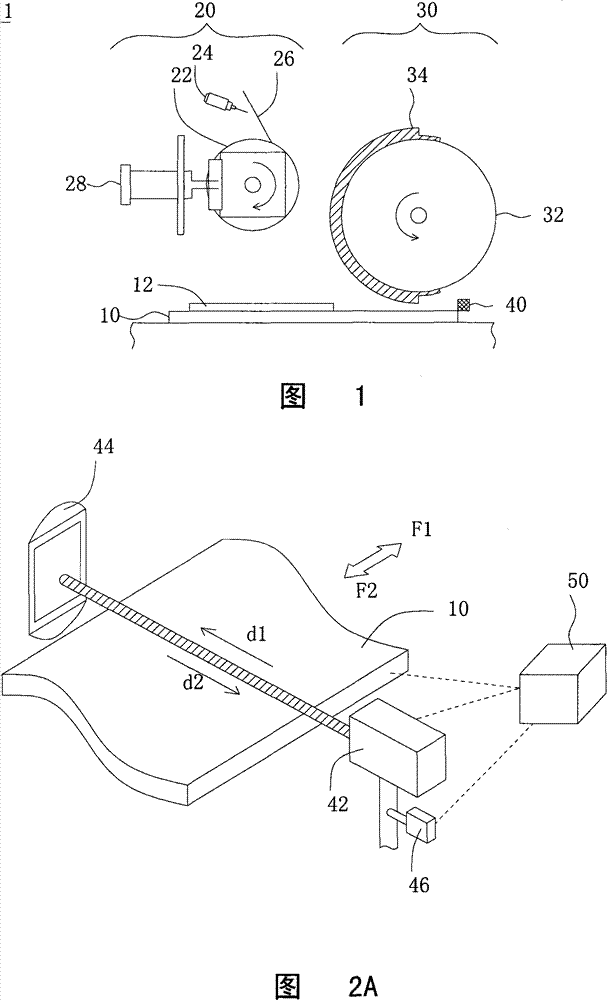

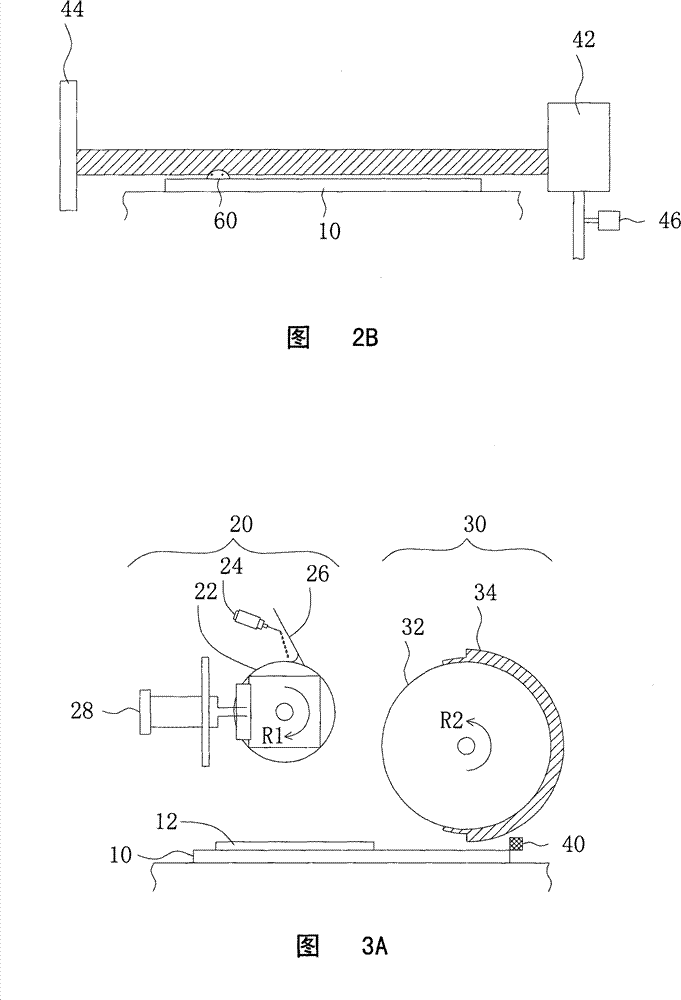

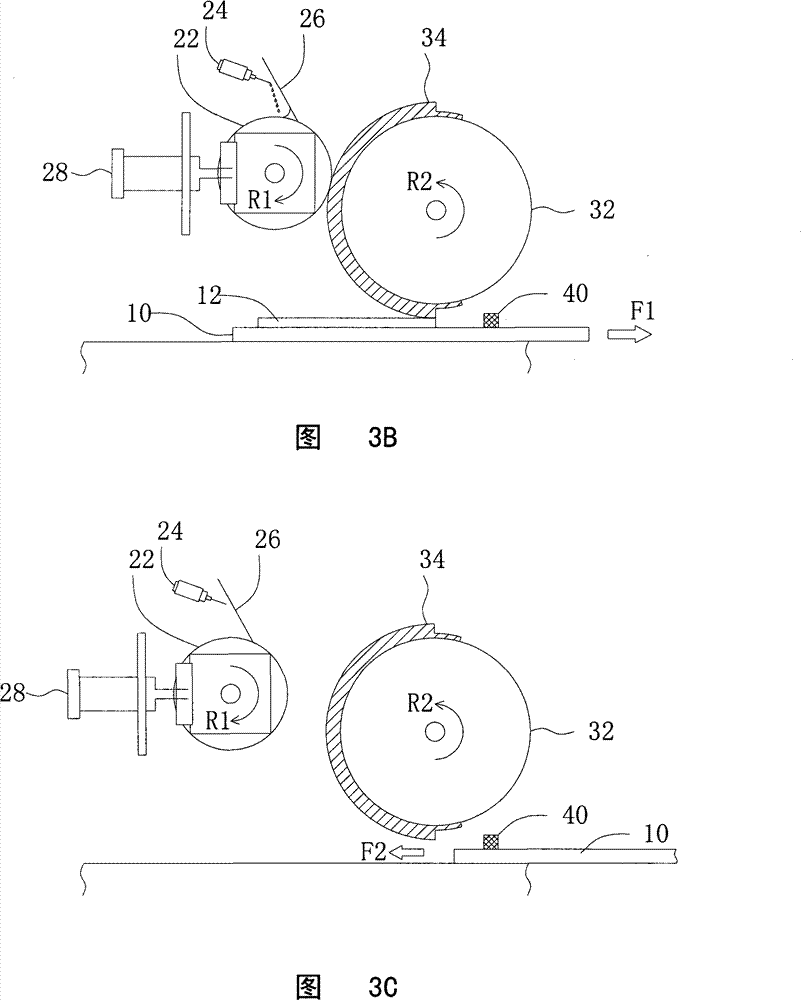

[0049] Please refer to figure 1 , which shows a schematic diagram of an alignment film manufacturing machine according to a preferred embodiment of the present invention. The manufacturing machine 1 at least includes a platform (Table) 10 , a material supply assembly (Material Supply Assembly) 20 , a film formation assembly (Film Formation Assembly) 30 and a reflective sensing assembly 40 . Wherein, a substrate 12 of a liquid crystal display element, such as a thin film transistor substrate (TFT substrate) or a color filter substrate (CF substrate), is movably carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com