Tunable interferometer for filling microstructure optical fiber based on functional material

A technology of micro-structured optical fiber and functional materials, which is applied in cladding optical fiber, optical waveguide coupling, optics, etc., can solve the problems of micro-structured optical fiber tunable interferometer that have not been reported in literature and patent reports, and achieve wide tuning range and realize Flexible and tuneable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: description in conjunction with accompanying drawing.

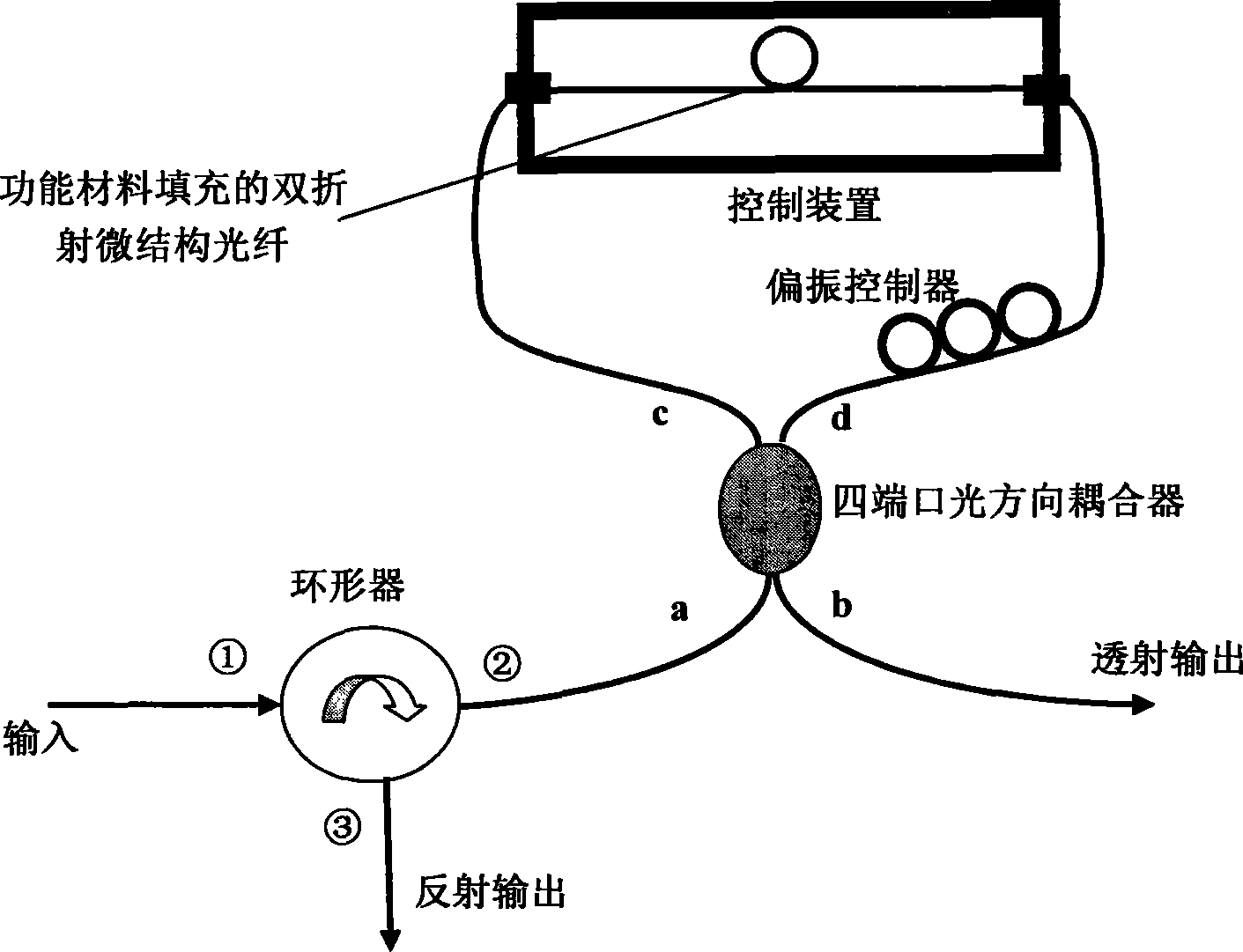

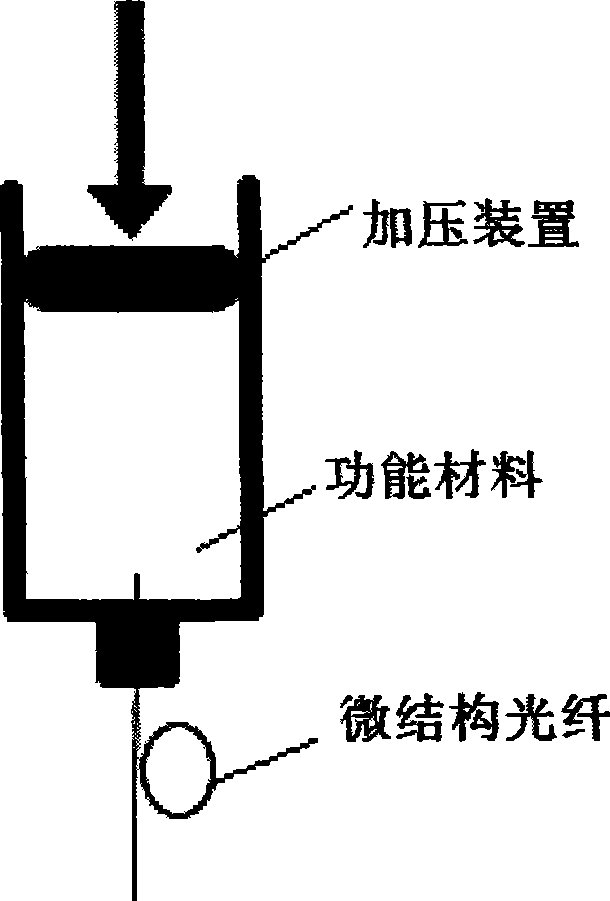

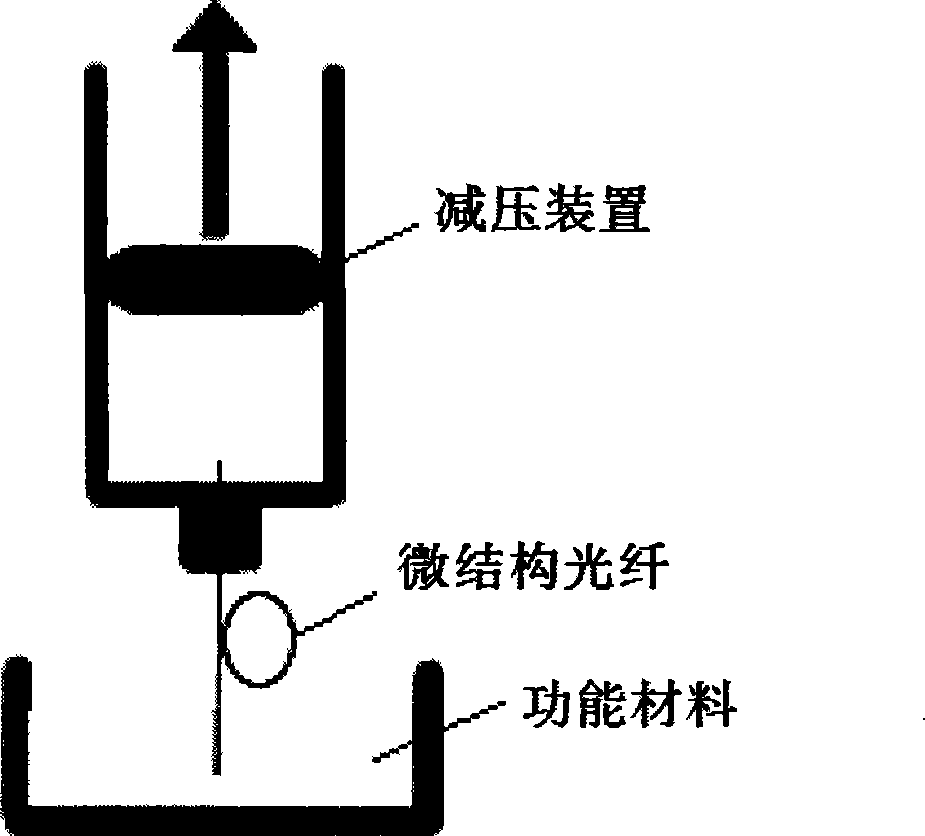

[0025] A tunable interferometer based on functional material filled microstructured optical fiber, see figure 1 , which is composed of birefringent microstructured fiber filled with functional material, control device, four-port optical directional coupler, polarization controller and circulator; the birefringent microstructured fiber filled with functional material is located in the control device, and the microstructure filled with functional material One end of the fiber is connected to port c of the four-port optical directional coupler, the other end is connected to one end of the polarization controller, and the other end of the polarization controller is connected to port d of the four-port optical directional coupler; Port a is connected to the ② port of the circulator, the ① port of the circulator is used as the input port of the interferometer, the ③ port of the circulator is used as the refle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com