Fuzzy control method and system based on successive type fuzzy interpolation

A technology of fuzzy control and fuzzy control quantity, applied in general control systems, control/regulation systems, adaptive control and other directions, can solve problems such as poor control accuracy and loss of fuzzy inference information, and achieve fast response speed and strong anti-interference ability. , the effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation of the present invention will now be described in detail in conjunction with the accompanying drawings and embodiments.

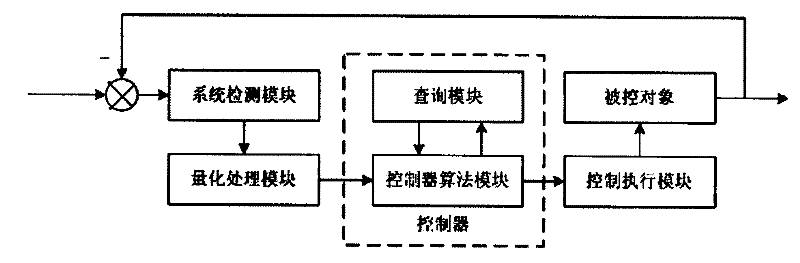

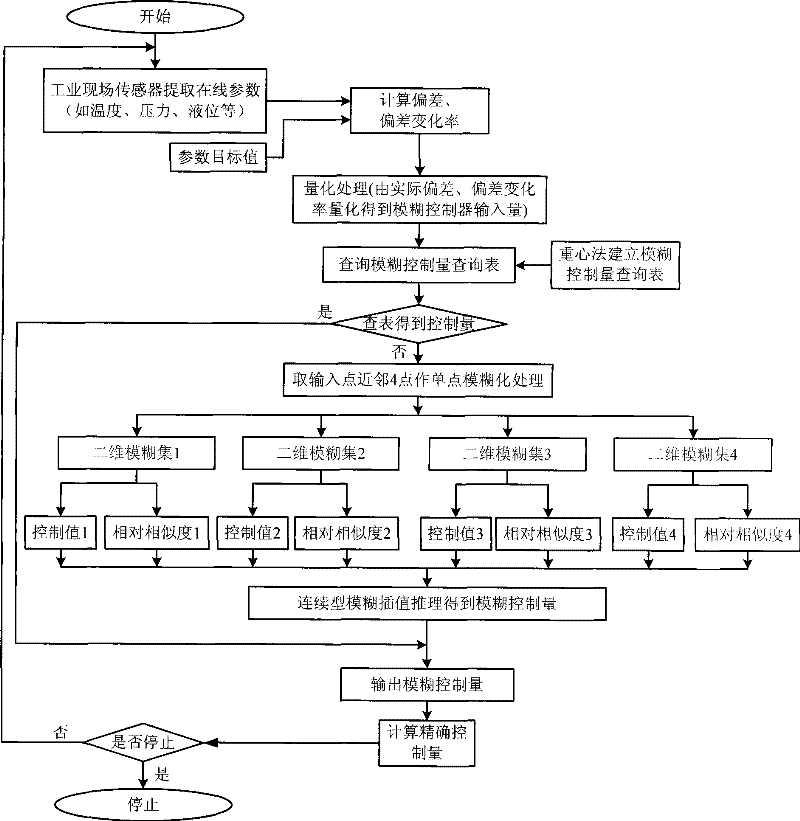

[0013] like figure 1 Shown is a fuzzy control system module structure diagram based on continuous fuzzy interpolation. The present invention uses sensors to extract on-line control object related parameters in the industrial field control process as system input (input includes temperature, pressure, liquid level, etc.), and calculates Its deviation and the rate of change of the deviation; the deviation and the rate of change of the deviation are quantified within the value range to obtain finite discrete values, which constitute the discrete domain of controller input, which is determined by the empirical data and rule base through the center of gravity method. Clear processing, the query module establishes the fuzzy control quantity query table of the relationship between the deviation fuzzy quantity, the deviation change rate fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com