Freestanding bi-convex-pole fault-tolerance motor

A double-salient, independent technology, applied in the fields of motors, electricians, and controls, can solve the problems of reduced operating capacity of motors with faults, complex rotor structure, and difficult heat dissipation of permanent magnets, etc., to improve operating capacity with faults and small moment of inertia , the effect of not easy to demagnetize at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

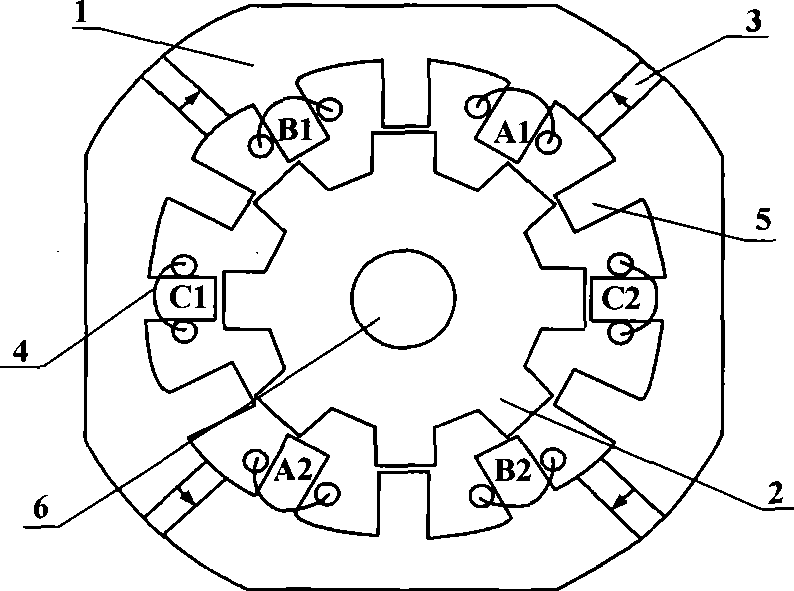

[0010] Taking a 12 / 8-pole stand-alone doubly salient pole fault-tolerant motor as an example, its cross-section is as follows: figure 1 shown. The independent doubly salient pole fault-tolerant motor of the present invention is composed of a stator 1, a rotor 2, a permanent magnet 3 and an armature winding 4 fixed on the stator 1. Wherein, the stator salient poles are evenly distributed on the inner circumference of the stator 1 , and the permanent magnets 3 are symmetrically distributed on the stator 1 . The stator is composed of 12 salient pole stator cores 1 and 4 permanent magnets 3 . Stator core 1 and rotor core 2 are punched out of silicon steel sheets with a thickness of 0.35mm respectively, and sufficient punches are stacked to form stator core 1 and rotor core 2 . The stator armature winding 4 is a concentrated winding, each coil winding is wound on a stator tooth, there is a set of coil windings separated by a fault-tolerant tooth 5, and there is only one set of wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com