Arca extract enteric-coated capsules and manufacture method thereof

A technology of enteric-coated capsules and manufacturing methods, which is applied in the field of marine biological drugs, can solve problems such as unseen reports, and achieve the effects of prolonging survival time, stable effect, and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

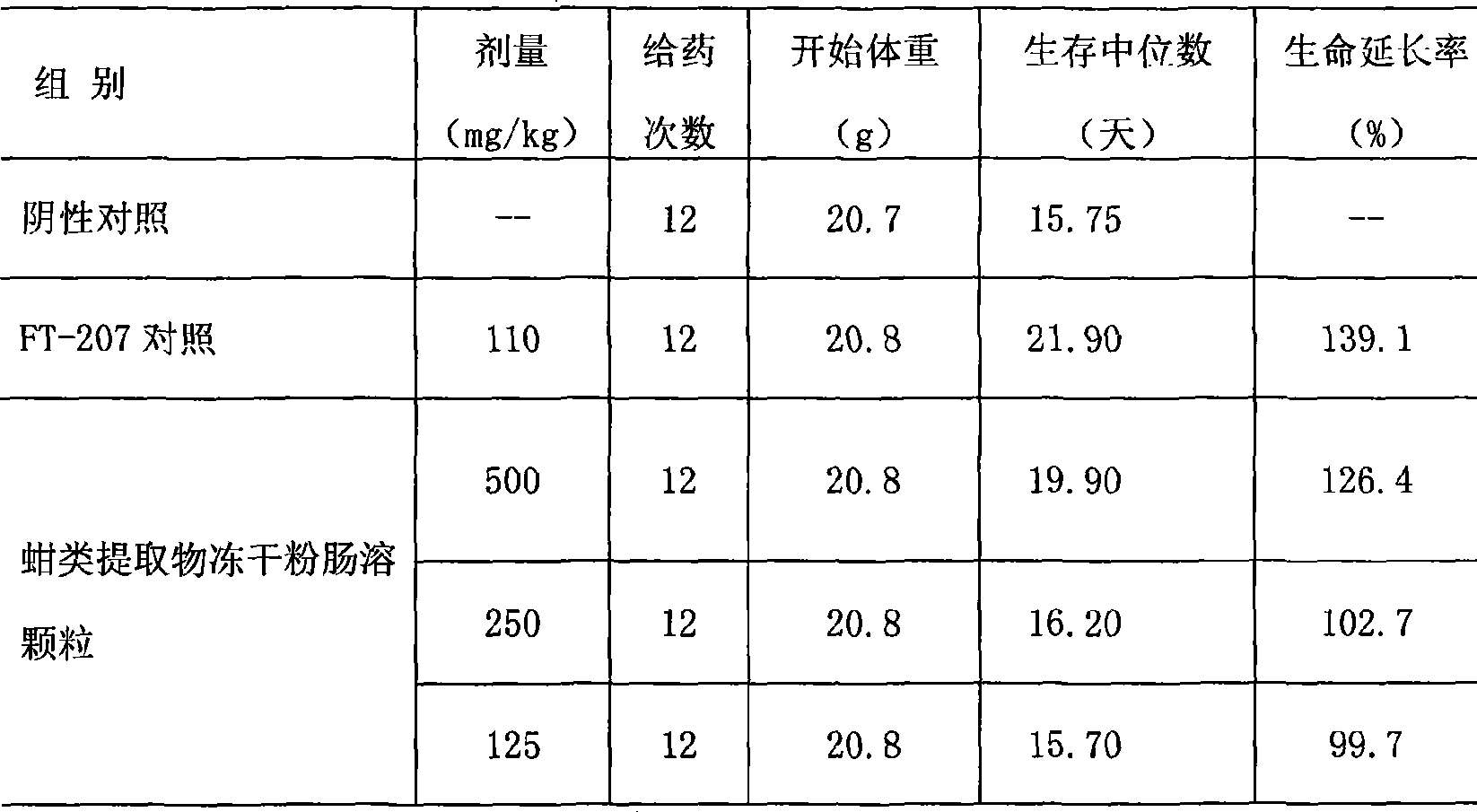

Examples

Embodiment 1

[0101] Take 400kg of fresh cockles, wash them repeatedly with drinking water until the surface of the shells is free of mud, then wash them three times with purified water, remove the shells and take soft tissues, wash them with purified water until there is no blood stain, drain the water and weigh 88Kg of the net materials. Crush it with a masher, the particle size is 0.3cm, add purified water at a weight ratio (w / w) of 1:1.5, stir and extract with a mixer at a slow speed (60r / min) for 4 hours at 0-10°C, and put the extract in GQ105 Centrifuge in a high-speed tubular centrifuge (20000r / min) to remove slag, and freeze-dry to obtain 5.16Kg of freeze-dried powder with a yield of 5.87% by weight. The mixture is evenly mixed, vacuum-packed, and placed in a refrigerator. The freeze-dried powder is a light yellow-brown loose powder, with a drying loss of 3.0%, a nitrogen content of 75 mg / g, a glucose content of 32.9 mg / g, and a residue on ignition of 3.8% by weight.

Embodiment 2-4

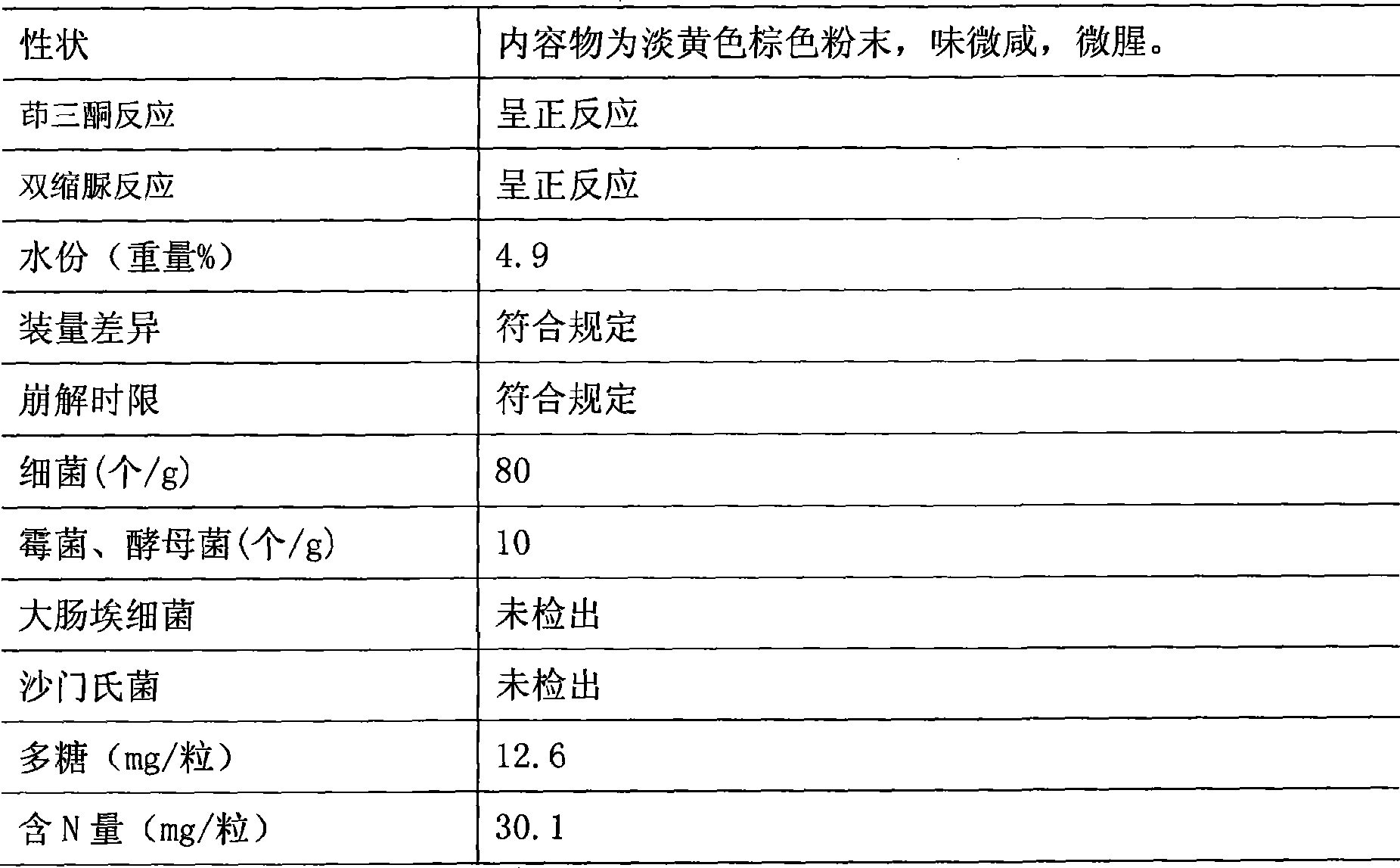

[0103] In Example 2, take 4 kg of the freeze-dried powder of the clam extract from Example 1, add 0.08 kg of silicon dioxide and 0.04 kg of magnesium stearate, mix well, and pack into enteric-coated capsules to make 10,000 enteric-coated capsules of the extract of clams in total. The properties and characteristics of the dissolved capsules are shown in Table 9.

[0104] Table 9

[0105]

[0106] Embodiment 3 manufacturing process is identical with embodiment 2, and different embodiment 3 silicon dioxide is 0.08kg, magnesium stearate 0.08kg.

[0107] Embodiment 4 manufacturing process is identical with embodiment 2, and different embodiment 4 silicon dioxide is 0.12kg, magnesium stearate 0.08kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com